Volkswagen Golf Variant / Jetta. Manual - part 525

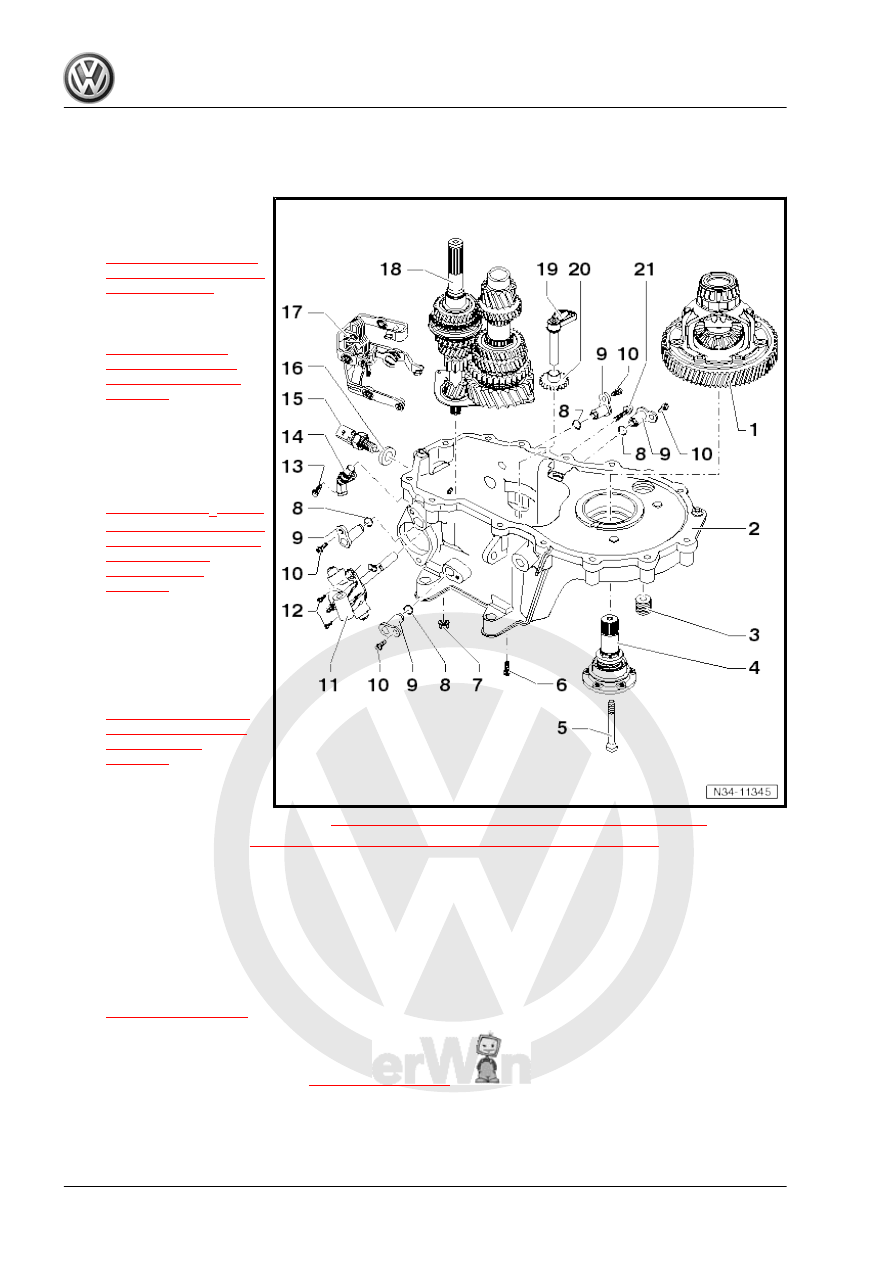

Overview - Input Shaft, Output Shaft, Differential Selector Mechanism and

Shift Rods, Removing and Installing

1 - Differential

❑ Disassembling and as‐

sembling. Refer to

2 - Transmission Housing

❑ Servicing. Refer to

❑ Shim S1 for the differen‐

tial outer race/tapered

roller bearing if deleted

from transmission date

of manufacture

04/12/2006. Refer to

❑ Outer race/tapered roll‐

er bearing seat adapted

in transmission housing

3 - Oil Drain Plug

❑ Tightening specifica‐

tion. Refer to

4 - Flange Shaft with Pressure

Spring

❑ Removing and installing. Refer to

⇒ “6.6 Disassembly and Assembly Sequence”, page 117

.

❑ Assembling. Refer to

⇒ “2.1 Differential, Disassembling and Assembling”, page 173

5 - Bolt

❑ 25 Nm

6 - Bolt

❑ 5 Nm and 90° additional turn

❑ Self-locking

❑ Replace after removing

❑ for securing bearing mount with grooved ball bearing for input and output shaft -item 18-

7 - Hex Collar Bolt

❑ 23 Nm

❑ For shift mechanism -item 17-

❑ Self-locking

❑ Replace after removing

116