Volkswagen Golf Variant / Jetta. Manual - part 385

oil supply line.

– Remove the camshaft toothed belt sprocket and remove the

camshaft hub using the Puller - Camshaft Sprocket - T10052- .

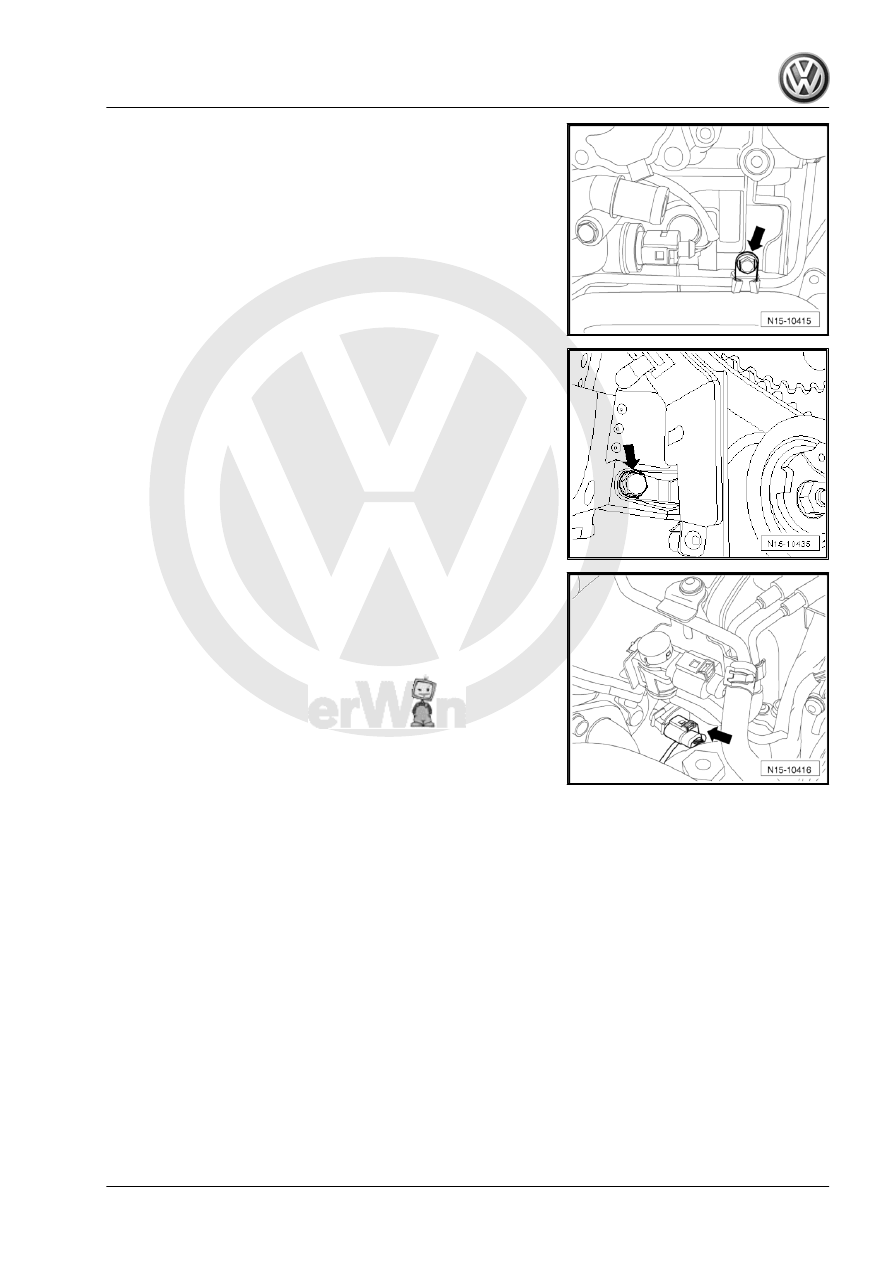

– Remove the bolt -arrow- on the toothed belt guard.

– Remove the nut on the toothed belt tensioning roller.

– Disconnect the connector for the Camshaft Position Sensor -

G40- -arrow-.

1. Cylinder Head

123