Volkswagen Golf Variant / Jetta. Manual - part 182

⇒ Fig. ““Selector Lever/Relay Lever Installed Position”“ , page 76

9 - Cap

❑ For the transmission ventilation

10 - Lock Washer

❑ Always replace.

❑ Not needed for the plastic relay lever

11 - Cap

12 - Spring

❑ Not installed in all transmissions

❑ Install if present

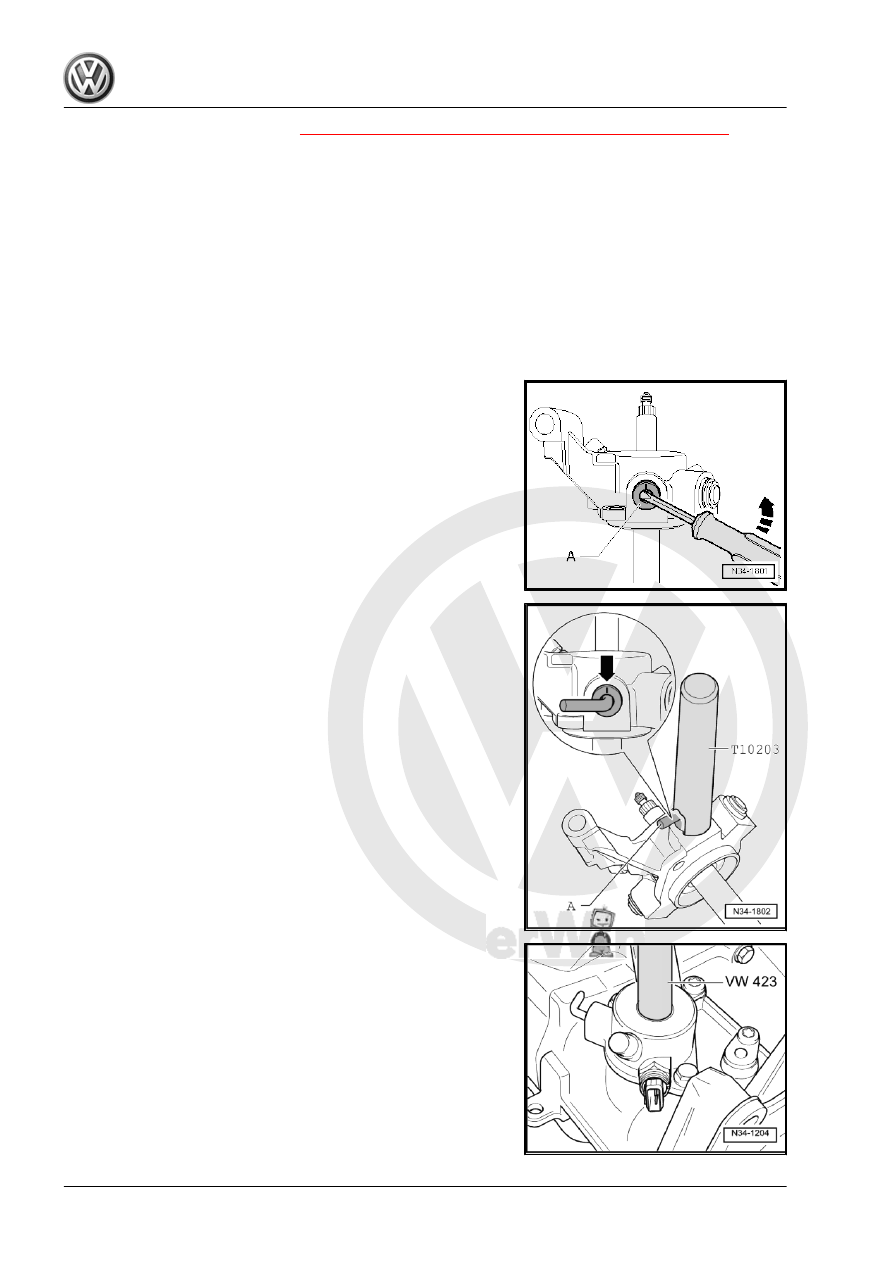

Removing the locking elbow -A- from the shift cover

– Remove the outer part of the locking elbow.

– Remove the locking elbow carefully with a screwdriver.

Pressing the locking elbow -A- into selector cover

Installation position:

The marking -arrow- faces toward upper part of gearshift shaft.

Installing the seal

190