Volkswagen Golf Variant / Jetta. Manual - part 173

Subframe Mount

⇒ “4.1 Overview - Subframe Mount”, page 154

4.1

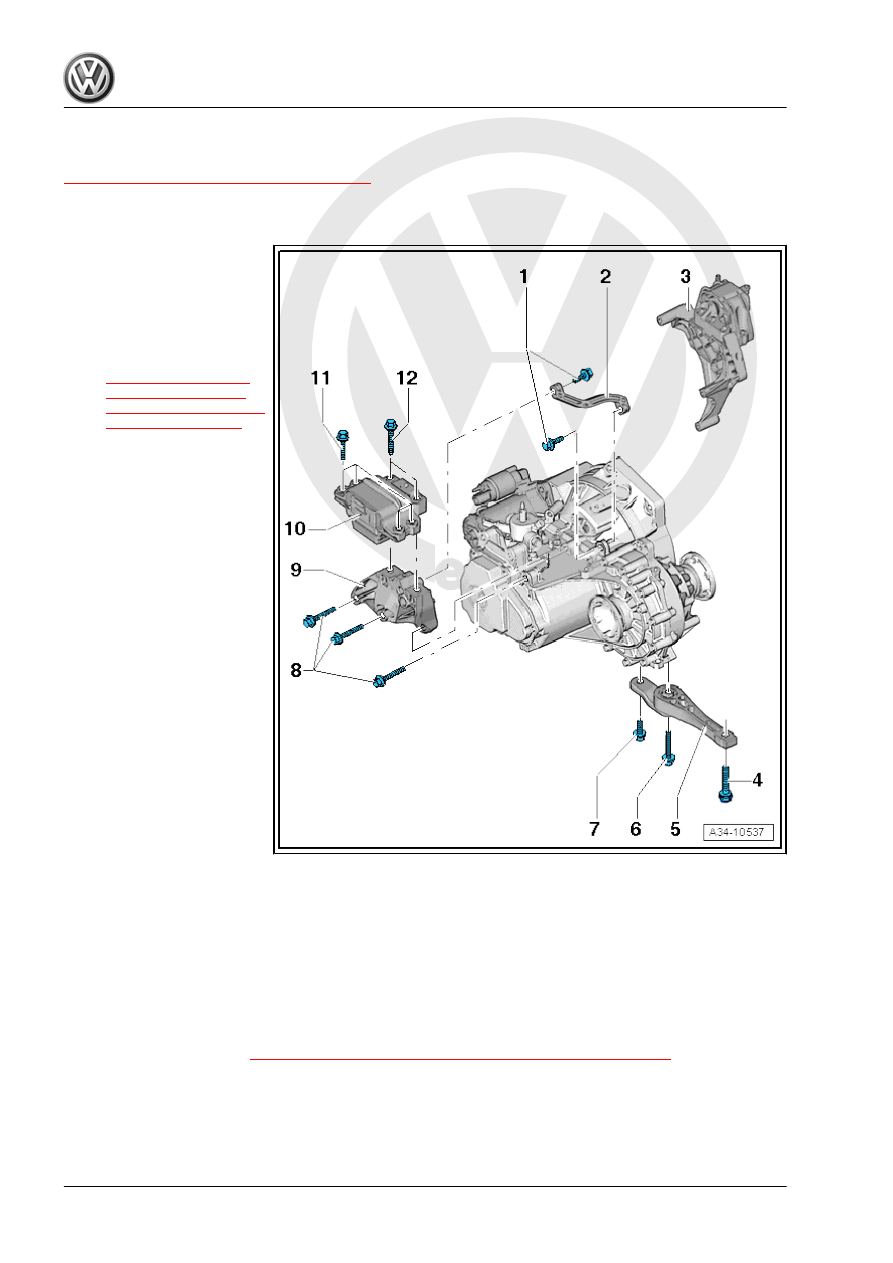

Overview - Subframe Mount

1 - Bolt

❑ 20 Nm +90°

❑ Transmission support to

transmission bracket

and transmission

❑ Tightening sequence.

Refer to

❑ Replace after removing

2 - Transmission Support

❑ To the transmission

bracket and transmis‐

sion

3 - Engine Mount with Engine

Support

Subframe Mount .

4 - Bolt

❑ Pendulum support to

subframe

❑ Refer to ⇒ Suspension,

Wheels, Steering; Rep.

Gr. 40 ; Subframe;

Overview - Subframe .

5 - Pendulum Support

❑ Refer to ⇒ Suspension,

Wheels, Steering; Rep.

Gr. 40 ; Subframe;

Overview - Subframe .

6 - Bolt

❑ Pendulum support to

transmission

❑ Refer to ⇒ Suspension, Wheels, Steering; Rep. Gr. 40 ; Subframe; Overview - Subframe .

7 - Bolt

❑ Pendulum support to transmission

❑ Refer to ⇒ Suspension, Wheels, Steering; Rep. Gr. 40 ; Subframe; Overview - Subframe .

8 - Bolt

❑ 40 Nm +90°

❑ Transmission bracket to transmission.

❑ Tightening sequence

⇒ Fig. ““Transmission Bracket -A- to Transmission.”“ , page 155

❑ Replace after removing

9 - Transmission Bracket

10 - Transmission Mount

154