Volkswagen Golf Variant / Jetta. Manual - part 67

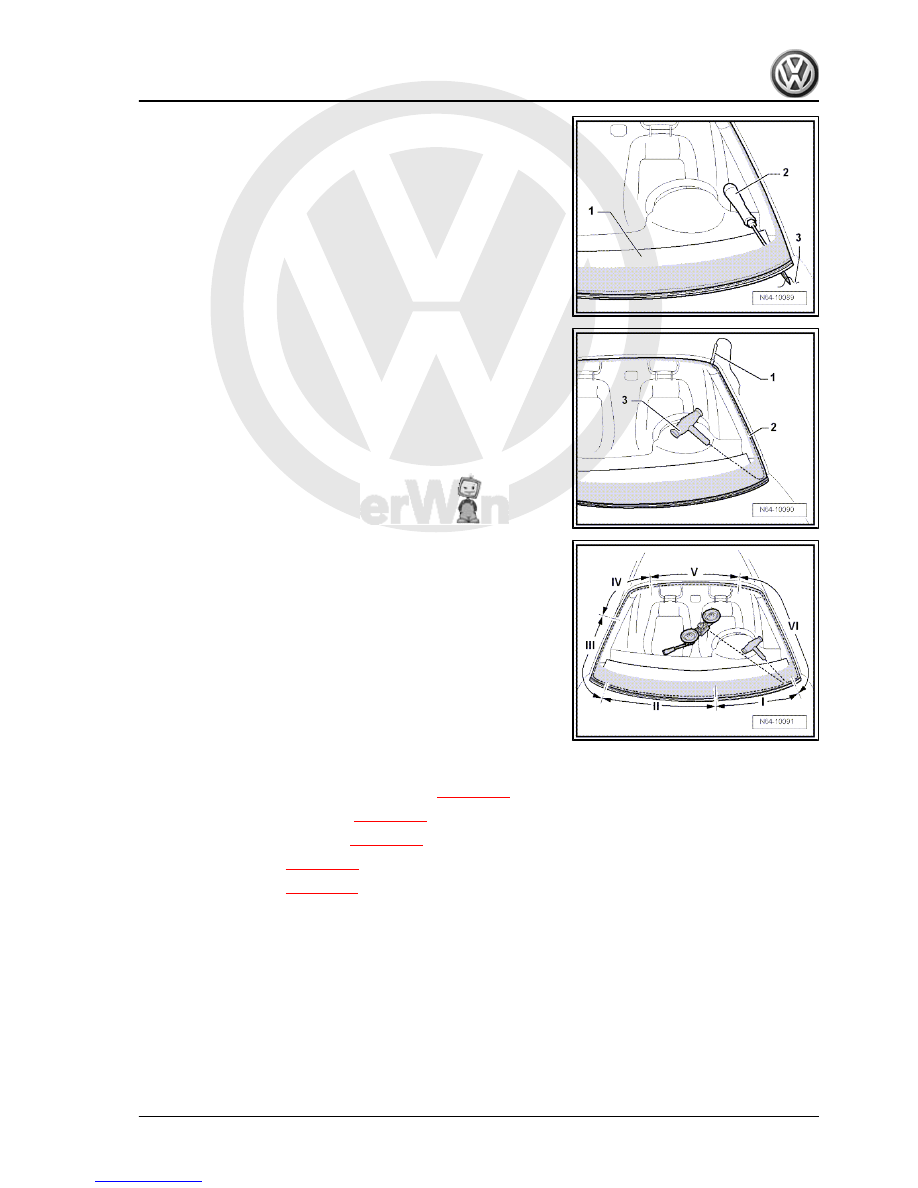

– Thrust awl -V.A.G 1474/2- -2- through adhesive bead.

– Pull cutting cord -3- through adhesive sealing material into in‐

side of vehicle using awl -V.A.G 1474/2- -2-.

– Secure inside end of cutting cord against falling out using pull

handle -V.A.G 1351/1- -3-.

– Place cutting cord -2- using small tube -1- in upper area of

window.

– Lay cutting cord -2- around window and guide second end of

cord inwards into interior.

Ensure that cutting cord -2- lies under window in corners.

– Secure other end of cord to reel device -V.A.G 1654- .

– Position reel device -V.A.G 1654- in “position I”.

– Reposition reel device -V.A.G 1654- as necessary and cut

window free.

– Use wedge -V.A.G 1474/5- to press cutting cord against win‐

dow glass while cutting in order to avoid damaging dash panel

and to create clearance at window flange.

1.6.2

Installing windscreen

Preparing used undamaged window for glazing

⇒ page 274

Preparing new window for glazing

⇒ page 274

Preparing body flange for glazing

⇒ page 275

Installation instructions

⇒ page 276

.

Minimum curing period

⇒ page 276

1. Flush bonded windows

265