Volkswagen Golf / Golf Plus. Manual - part 52

Special tools and workshop

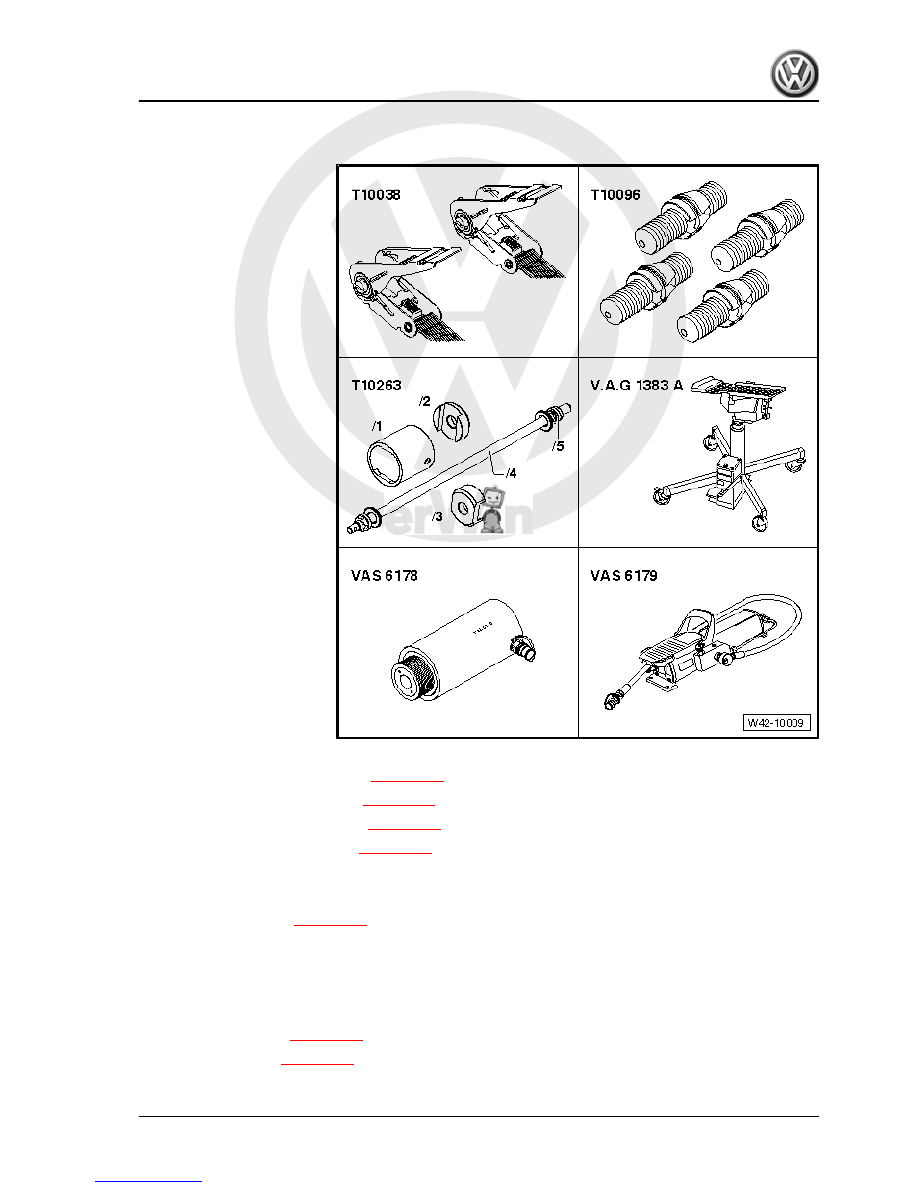

equipment required

♦ Tensioning strap -T10038-

♦ Locating pins -T10096-

♦ Assembly tool -T10263-

♦ Engine and gearbox jack -

V.A.G 1383 A-

♦ Hydraulic press -VAS

6178- and thrust piece -

T10205/13-

♦ Foot pump -VAS 6179-

Pulling out front bonded rubber bush

⇒ page 205

Pulling in front bonded rubber bush

⇒ page 207

Pulling out rear bonded rubber bush

⇒ page 208

Pulling in rear bonded rubber bush

⇒ page 210

Pulling out front bonded rubber bush

– Remove rear wheels.

– Removing coil spring

⇒ page 257

.

– Remove rear exhaust system silencer ⇒ Rep. Gr. 26 ; Ex‐

haust system; Removing and installing parts of the exhaust

system .

– Disconnect electrical connections between rear axle and

body.

– Remove anti-roll bar

⇒ page 265

.

– Remove track rods

⇒ page 231

.

10. Assembly overview - subframe made from steel, final drive (four-wheel drive)

205