Volkswagen Golf / Golf Plus. Manual - part 2

2.1

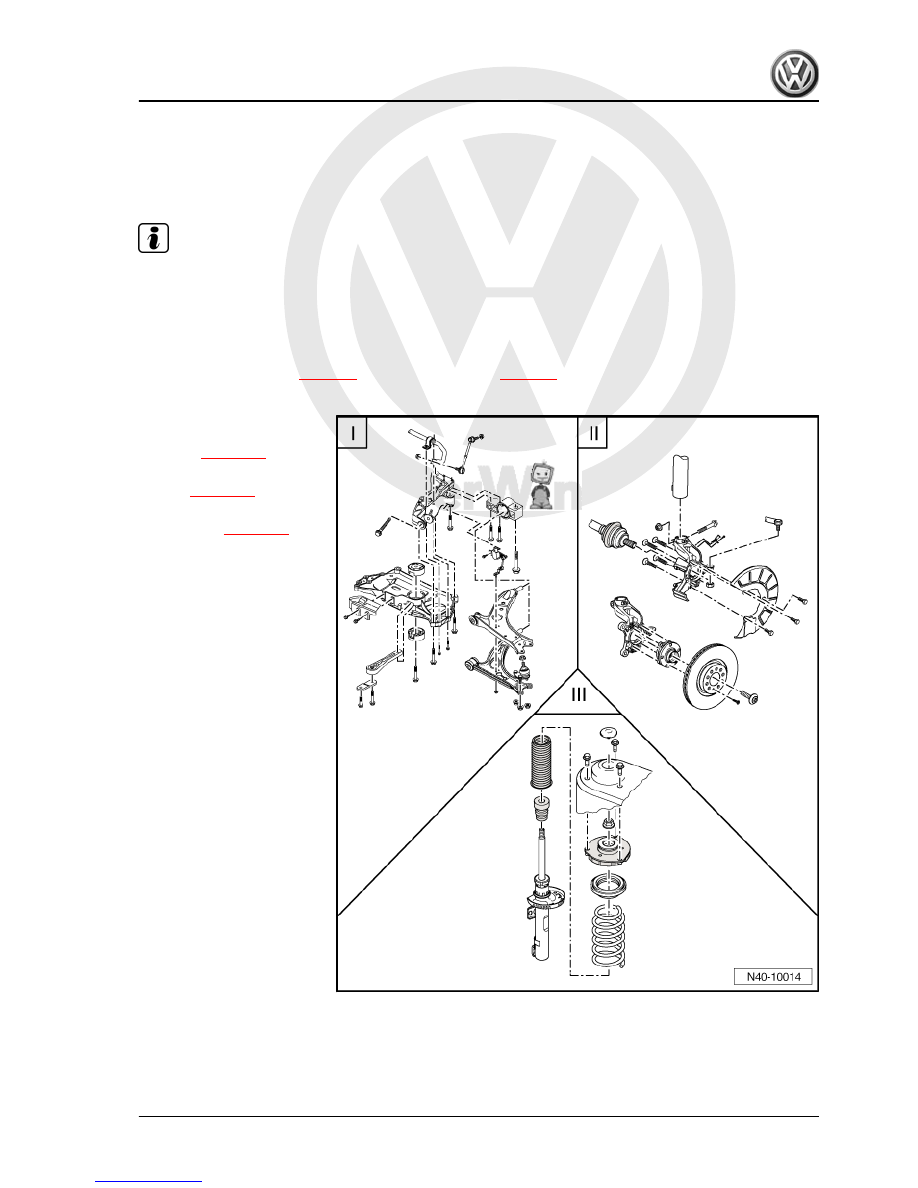

Overview - front axle

Note

♦

It is not permitted to weld or straighten load-bearing or wheel-guiding components of the suspension.

♦

Always renew self-locking nuts.

♦

Always renew corroded nuts and bolts.

♦

Bonded rubber bushes can be twisted only to a limited extent. Therefore, you should only tighten the threa‐

ded connections of components with bonded rubber bushes when the wheel bearing housing is raised to

unladen position, Golf

⇒ page 6

; Golf Plus, CrossGolf

⇒ page 8

.

I - Assembly overview - sub‐

frame, anti-roll bar, suspen‐

sion links

⇒ page 10

II - Assembly overview - wheel

bearing

⇒ page 56

III - Assembly overview - sus‐

pension strut

⇒ page 64

2. Repairing front suspension

5