Toyota Corolla (2004+). Manual - part 20

32-5

BRAKE

- BRAKE FLUID

(e) Repeat the above procedures to bleed the air out of the

brake line for each wheel.

4.

CHECK FLUID LEVEL IN RESERVOIR

(a) Check the fluid level and add fluid if necessary.

Fluid: SAE J1703 or FMVSS No. 116 DOT3

C80823

32-24

BRAKE

- FRONT BRAKE

FRONT BRAKE

320II-01

COMPONENTS

Union Bolt

29 (296, 21)

Front Disc

Front Disc Brake

F Gasket

Cylinder Sliding Pin

106.8 (1,089, 79)

Flexible Hose

F Bush Dust Boot

106.8 (1,089, 79)

Front Disc Brake

Cylinder Mounting LH

Front Disc

Pad Wear

Brake Cylinder

Indicator Plate

Anti-squeal Shim No.1

Sliding Pin

F Bush Dust Boot

Front Disc Brake Pad Support Plate

Anti-squeal

Pad Wear Indicator

Shim No.2

Plate

Anti-squeal Shim No.2

Disc Brake Pad

Kit Front

Bleeder Plug Cap

Front Disc Brake

34.3 (350, 25)

Pad Support Plate

Disc Brake Pad

Kit Front

Disc Brake Cylinder

Anti-squeal Shim No.1

Bleeder Plug

8.3 (85, 74 in.·lbf)

Assy LH

FCylinder Boot

34.3 (350, 25)

FPiston Seal

FSet Ring

Front Disc Brake Piston

N·m (kgf·cm, ft·lbf)

: Specified torque

F Non-reusable part

Lithium soap base glycol grease

Disc brake grease

F42829

32-25

BRAKE

- FRONT BRAKE

320IJ-01

OVERHAUL

HINT:

Overhaul the RH side by the same procedure as the LH side.

1.

REMOVE FRONT WHEEL

2.

DRAIN BRAKE FLUID

NOTICE:

Wash the brake fluid off immediately if it comes into contact with any painted surface.

3.

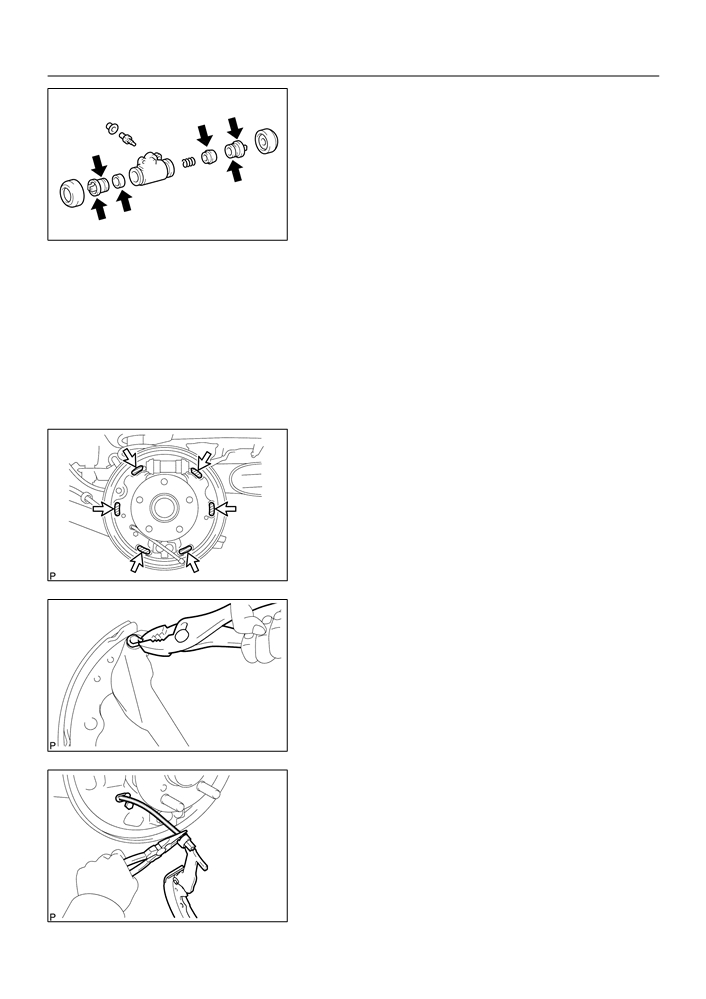

REMOVE FRONT DISC BRAKE CYLINDER

SUB-ASSY

(a) Remove the union bolt and gasket from the disc brake cyl-

inder, then disconnect the flexible hose.

HINT:

Gasket has 2 types: 2-piece type and 1-piece type.

C86274

(b) Hold the cylinder slide pin and remove the 2 bolts.

C86275

4.

REMOVE DISC BRAKE PAD KIT FRONT (PAD ONLY)

(a) Remove the 2 brake pads with anti-squeal shims.

(b) Remove the anti-squeal shim No.1 and anti-squeal shim No.2 from each pad.

5.

REMOVE FRONT DISC BRAKE PAD SUPPORT PLATE

(a) Remove the 2 front disc brake pad support plates from the cylinder mounting.

6.

REMOVE FRONT DISC BRAKE CYLINDER SLIDE PIN

(a) Remove the 2 cylinder slide pins from the disc brake cylinder mounting.

7.

REMOVE FRONT DISC BRAKE CYLINDER

MOUNTING LH

(a) Remove the 2 bolts and disc brake cylinder mounting.

F41561

32-26

BRAKE

- FRONT BRAKE

8.

REMOVE FRONT DISC BRAKE BUSH DUST BOOT

(a) Place front disc brake cylinder mounting in vise.

(b) Using a screwdriver and hammer, remove the 2 bush dust

boots from the disc brake cylinder mounting.

C68791

9.

REMOVE CYLINDER BOOT

(a) Using a screwdriver, remove the set ring and cylinder

boot.

R09298

10. REMOVE FRONT DISC BRAKE PISTON

(a) Place a piece of cloth or similar, between the piston and

the disc brake cylinder.

(b) Use compressed air to remove the piston from the disc

brake cylinder.

CAUTION:

Do not place your fingers in front of the piston when using

compressed air.

C64095

NOTICE:

Do not spatter the brake fluid.

11. REMOVE PISTON SEAL

(a) Using a screwdriver, remove the piston seal from the disc brake cylinder.

12. REMOVE FRONT DISC BRAKE BLEEDER PLUG

(a) Remove the bleeder plug cap and bleeder plug from the disc brake cylinder.

13. INSPECT BRAKE CYLINDER AND PISTON

(a) Check the cylinder bore and piston for rust or scoring.

14. INSPECT PAD LINING THICKNESS

(a) Using a ruler, measure the pad lining thickness.

Standard thickness: 11.0 mm (0.433 in.)

Minimum thickness: 1.0 mm (0.039 in.)

R02951

32-27

BRAKE

- FRONT BRAKE

15. INSPECT FRONT DISC BRAKE PAD SUPPORT PLATE

(a) Make sure that they have sufficient rebound, no deformation, cracks or wear, and have had all rust and

dirt cleaned off.

16. INSPECT DISC THICKNESS

(a) Using a micrometer, measure the disc thickness.

Standard thickness: 25.0 mm (0.984 in.)

Minimum thickness: 23.0 mm (0.906 in.)

F42895

17. REMOVE FRONT DISC

Matchmarks

(a) Make matchmarks on the front disc and the axle hub.

(b) Remove the front disc.

18. INSTALL FRONT DISC

(a) Aligning the matchmarks, install the front disc.

HINT:

Select the installation position where the front disc has the mini-

mum runout.

F41543

19. INSPECT DISC RUNOUT

(a) Temporarily fasten the disc with hub nuts.

Torque: 103 N m (1,050 kgf cm, 76 ft lbf)

(b) Using a dial indicator, measure the disc runout 10 mm

(0.39 in.) away from the outer edge of the disc.

Maximum disc runout: 0.05 mm (0.0020 in.)

(c)

If the disc runout is the maximum value or greater, check

the bearing play in the axial direction and check the axle

F42896

hub runout (See page 30-2). If the bearing play and axle

hub runout are normal, adjust the disc runout or grind it

on a ”On-car” brake lathe.

20.

TEMPORARY TIGHTEN FRONT DISC BRAKE BLEEDER PLUG

(a)

Temporarily tighten the bleeder plug, and install bleeder plug cap to the disc brake cylinder.

21.

INSTALL PISTON SEAL

(a)

Apply the lithium soap base glycol grease on a new piston seal.

(b)

Install the piston seal to the disc brake cylinder.

22.

INSTALL FRONT DISC BRAKE PISTON

(a)

Apply the lithium soap base glycol grease on the piston.

(b)

Install the piston to the disc brake cylinder.

NOTICE:

Do not screw the piston forcedly in the disc brake cylinder.

32-28

BRAKE

- FRONT BRAKE

23. INSTALL CYLINDER BOOT

(a) Apply the lithium soap base glycol grease to a new cylin-

der boot. Install the cylinder boot to the disc brake cylin-

der.

HINT:

Install the boot securely to the grooves of the cylinder and pis-

ton.

(b) Using a screwdriver, install the set ring.

F42832

NOTICE:

Do not damage the cylinder boot.

24. INSTALL FRONT DISC BRAKE BUSH DUST BOOT

(a) Place front disc brake cylinder mounting in vise.

(b) Apply the lithium soap base glycol grease to seal surface

of 2 new bush dust boots.

(c)

Using a socket wrench (19 mm) and hammer, drive the 2

bush dust boots to the disc brake cylinder mounting.

C68792

25. INSTALL FRONT DISC BRAKE CYLINDER MOUNTING LH

(a) Install the disc brake cylinder mounting LH with the 2 bolts.

Torque: 106.8 N m (1,089 kgf cm, 79 ft lbf)

26. INSTALL FRONT DISC BRAKE CYLINDER SLIDE PIN

(a) Apply the lithium soap base glycol grease to the sliding part and the seal surface of the 2 cylinder slide

pins.

(b) Install the 2 cylinder slide pins to the disc brake cylinder mounting.

27. INSTALL FRONT DISC BRAKE PAD SUPPORT PLATE

(a) Install the 2 front disc brake pad support plates to the cylinder mounting.

Anti-squeal

28. INSTALL DISC BRAKE PAD KIT FRONT (PAD ONLY)

Front Disc Brake

Shim No.2

Pad Wear Indicator Plate

NOTICE:

If necessary, replace the anti-squeal shim kit when replac-

Anti-squeal

ing the brake pad.

Shim No.1

Anti-squeal

(a) Apply disc brake grease to each anti-squeal shim No.1.

Anti-squeal

Shim No.2

(b) Install anti-squeal shims on each pad.

Shim No.1

(c)

Install the pad wear indicator plate facing upward, and

Disc Brake

install each pad.

Pad Kit

F42831

29. INSTALL FRONT DISC BRAKE CYLINDER SUB-ASSY

(a) Install the disc brake cylinder with the 2 bolts.

Torque: 34.3 N m (350 kgf cm, 25 ft lbf)

C86275

32-29

BRAKE

- FRONT BRAKE

(b) Install a new gasket and flexible hose with the union bolt.

Torque: 29 N m (296 kgf cm, 21 ft lbf)

HINT:

F

Gasket has 2 types: 2-piece type and 1-piece type.

F

Install the flexible hose lock securely in the lock hole in the

disc brake cylinder.

C86274

30. FILL RESERVOIR WITH BRAKE FLUID

31. BLEED MASTER CYLINDER (See page 32-4)

SST

09023-00100

32. BLEED BRAKE LINE (See page

32-4)

33. CHECK FLUID LEVEL IN RESERVOIR

34. CHECK BRAKE FLUID LEAKAGE

35. INSTALL FRONT WHEEL

Torque: 103 N m (1,050 kgf cm, 76 ft lbf)

32-1

BRAKE

- BRAKE SYSTEM

BRAKE SYSTEM

320I7-01

PRECAUTION

F

Care must be taken to replace each part properly, because it could affect the performance of

the brake system and result in a driving hazard. Replace the parts with the parts which have

the same part number or equivalent.

F

It is very important to keep parts and the area clean when repairing the brake system.

F

If the vehicle is equipped with a mobile communication system, refer to the precaution in the

introduction section.

32-38

BRAKE

- PROPORTIONING VALVE ASSY

PROPORTIONING VALVE ASSY

320IM-01

ON-VEHICLE INSPECTION

1.

INSTALL LSPV GAUGE (SST) AND BLEED AIR

(a) Remove the bleeder plugs from the front and rear brake cylinder.

(b) Install the LSPV gauge (SST), and bleed the air.

SST

09709-29018

SST

SST

C86277

2.

RAISE MASTER CYLINDER PRESSURE AND CHECK REAR WHEEL CYLINDER PRESSURE

Master cylinder pressure

Rear wheel cylinder pressure

2,942 kPa (30 kgf/cm2, 427 psi)

2,942 kPa (30 kgf/cm2, 427 psi)

4,903 kPa (50 kgf/cm2, 711 psi)

3,667 kPa (37 kgf/cm2, 531 psi)

7,845 kPa (80 kgf/cm2, 1,138 psi)

4,756 kPa (49 kgf/cm2, 689 psi)

HINT:

When inspecting the fluid pressure, inspect the left front and right rear together, and the right front and left

rear together.

If the rear wheel cylinder pressure is imprper, replace the proportioning valve assy.

3.

REMOVE LSPV GAUGE (SST)

(a) Remove the LSPV gauge (SST).

SST

09709-29018

(b) Install the bleeder plugs.

Torque: 8.3 N m (85 kgf cm, 74 in. lbf)

4.

BLEED MASTER CYLINDER (See page 32-4)

SST

09023-00100

5.

BLEED BRAKE LINE (See page 32-4)

6.

CHECK FOR LEAKS

32-39

BRAKE

- PROPORTIONING VALVE ASSY

320IN-01

REPLACEMENT

1.

REMOVE PROPORTIONING VALVE ASSY

(a) Using SST, disconnect the 5 brake tubes from the propor-

tioning valve assy.

SST

09023-00100

F42835

(b) Remove the 2 bolts and proportioning valve assy from the

body.

F42836

2.

INSTALL PROPORTIONING VALVE ASSY

(a) Install the proportioning valve assy with the 2 bolts.

Torque: 5.4 N m (55 kgf cm, 48 in lbf)

F42836

(b) Using SST, connect the 5 brake tubes to the proportioning

valve assy.

SST

09023-00100

Torque: 15.2 N m (155 kgf cm, 11 ft lbf)

F42835

3.

FILL RESERVOIR WITH BRAKE FLUID

4.

BLEED MASTER CYLINDER (See page 32-4)

SST

09023-00100

5.

BLEED BRAKE LINE (See page 32-4)

6.

CHECK FLUID LEVEL IN RESERVOIR

32-30

BRAKE

- REAR BRAKE

REAR BRAKE

320IK-01

COMPONENTS

Bleeder Plug

10 (102, 7)

8.3 (85, 74 in. lbf)

F

Cylinder

Bleeder Plug Cap

F Cylinder Cup

Dust Boot

15.2 (155, 11)

F Cylinder Cup

Hole Plug

Piston

Pin

F

Cylinder

Pin

Dust Boot

Piston

Compression Spring

Rear Wheel Brake

Cylinder Assy

FC-Washer

Parking Brake Shoe

Lever Sub-assy

Rear Brake Shoe

Return Spring

Parking Brake Shoe

Strut Set LH

Cup

Front Brake Shoe

Shoe Hold-down

Spring

Rear Brake Automatic

Adjust Lever LH

Tension Spring

Shoe Hold-down Spring

Tension Spring

Cup

Parking Brake Shoe

Strut Set LH

Rear Brake Drum Sub-assy

Nm (kgfcm, ftlbf)

: Specified torque

F Non-reusable part

Lithium soap base glycol grease

High temperature grease

F42669

32-31

BRAKE

- REAR BRAKE

320IL-01

OVERHAUL

HINT:

Overhaul the RH side by the same procedures with LH side.

1.

REMOVE REAR WHEEL

2.

DRAIN BRAKE FLUID

NOTICE:

Wash the brake fluid off immediately if it comes into contact with any painted surface.

3.

REMOVE REAR BRAKE DRUM SUB-ASSY

(a) Release the parking brake lever, and remove the brake

Contract

drum.

HINT:

If the brake drum cannot be removed easily, do the following

steps.

(b) Remove the hole plug and insert a screwdriver through

the hole in the backing plate, and hold the automatic ad-

F42837

justing lever away from the adjuster.

(c)

Using a another screwdriver, reduce the brake shoe ad-

juster by turning the adjusting wheel.

4.

INSPECT BRAKE DRUM INSIDE DIAMETER

(a) Using a brake drum gauge or equivalent, measure the in-

side diameter of the drum.

Standard inside diameter: 200.0 mm (7.874 in.)

Maximum inside diameter: 201.0 mm (7.913 in.)

F06408

5.

REMOVE REAR BRAKE AUTOMA TIC ADJUST LEVER

LH

(a) Using a needle-nose pliers, remove the upper side ten-

sion spring.

(b) Remove the rear brake automatic adjust lever LH from the

rear brake shoe.

F42670

32-32

BRAKE

- REAR BRAKE

6.

REMOVE FRONT BRAKE SHOE

(a) Using a needle-nose pliers, remove the anchor side ten-

sion spring.

F42671

(b) Using SST, remove the cup, shoe hold-down spring and

pin.

SST

09718-00010

(c)

Disconnect the upper side return spring from the front

SST

brake shoe, and remove the front brake shoe.

F42672

7.

REMOVE PARKING BRAKE SHOE STRUT SET LH

8.

REMOVE REAR BRAKE SHOE

(a) Using SST, remove the cup, shoe hold-down spring and

pin.

SST

09718-00010

SST

F42673

(b) Using a needle-nose pliers, disconnect the parking brake

cable No.3 and remove the rear brake shoe.

(c)

Remove the upper side return spring from the rear brake

shoe.

F42688

32-33

BRAKE

- REAR BRAKE

9.

REMOVE REAR BRAKE PARKING BRAKE SHOE

LEVER SUB-ASSY

(a) Using a screwdriver, remove the C-washer and parking

brake shoe lever.

F42689

10. INSPECT REAR DRUM B RAKE SHOE LINING

THICKNESS

(a) Using a ruler, measure the thickness of the shoe lining.

Standard thickness: 4.4 mm (0.173 in.)

Minimum thickness: 1.0 mm (0.039 in.)

If the lining thickness is at the minimum thickness or less, or if

there is severe, uneven wear, replace the brake shoe.

F42690

11. INSPECT BRAKE DRUM AND REAR DRUM BRAKE

SHOE LINING FOR PROPER CONTACT

(a) Apply chalk to the inside surface of the drum, then grind

drum on the brake shoe lining to fit.

If the contact between the drum and the shoe lining is improper,

repair it using a brake shoe grinder or replace the brake shoe

assembly.

R01564

12. REMOVE RH, FRONT OR UPPER REAR WHEEL

BRAKE CYLINDER ASSY

(a) Using SST, disconnect the brake tube, use a container to

catch brake fluid.

SST

09023-00100

(b) Remove the bolt and wheel cylinder.

F42691

13. REMOVE REAR WHEEL CYLINDER CUP KIT

(a) Remove the 2 cylinder dust boots from the wheel cylinder.

(b) Remove the 2 pistons and compression spring.

(c)

Remove the 2 wheel cylinder cups from each piston.

(d) Remove the bleeder plug cap and bleeder plug from the wheel cylinder.

14. INSPECT BRAKE WHEEL CYLINDER

(a) Check the cylinder bore and piston for rust or scoring.

32-34

BRAKE

- REAR BRAKE

15. INSTALL REAR WHEEL CYLINDER CUP KIT

(a) Temporary tighten the bleeder plug to the wheel cylinder,

and install the bleeder plug cap.

(b) Apply the lithium soap base glycol grease to 2 new wheel

cylinder cups and the 2 pistons.

(c)

Install the 2 wheel cylinder cups to each piston.

(d) Install the compression spring and 2 pistons to the wheel

cylinder.

F42692

(e) Install 2 new cylinder dust boots to the wheel cylinder.

16. INSTALL RH, FRONT OR UPPER REAR WHEEL BRAKE CYLINDER ASSY

(a) Install the wheel cylinder with the bolt.

Torque: 10 N m (102 kgf cm, 7 ft lbf)

(b) Using SST, connect the brake tube.

SST

09023-00100

Torque: 15.2 N m (155 kgf cm, 11 ft lbf)

17. APPLICATION HIGH TEMPERATURE GREASE

(a) Apply the high temperature grease to the shoe attached

surface of backing plate.

F42693

F42893

18. INSTALL REAR BRAKE PARKING BRAKE SHOE

LEVER SUB-ASSY

(a) Using a pliers, install the parking brake shoe lever with a

new C-washer.

F42694

19. INSTALL REAR BRAKE SHOE

(a) Using a needle-nose pliers, connect the parking brake

cable No.3 to the parking brake shoe lever.

F42688