Subaru Legacy IV (2008 year). Service manual - part 816

6MT-77

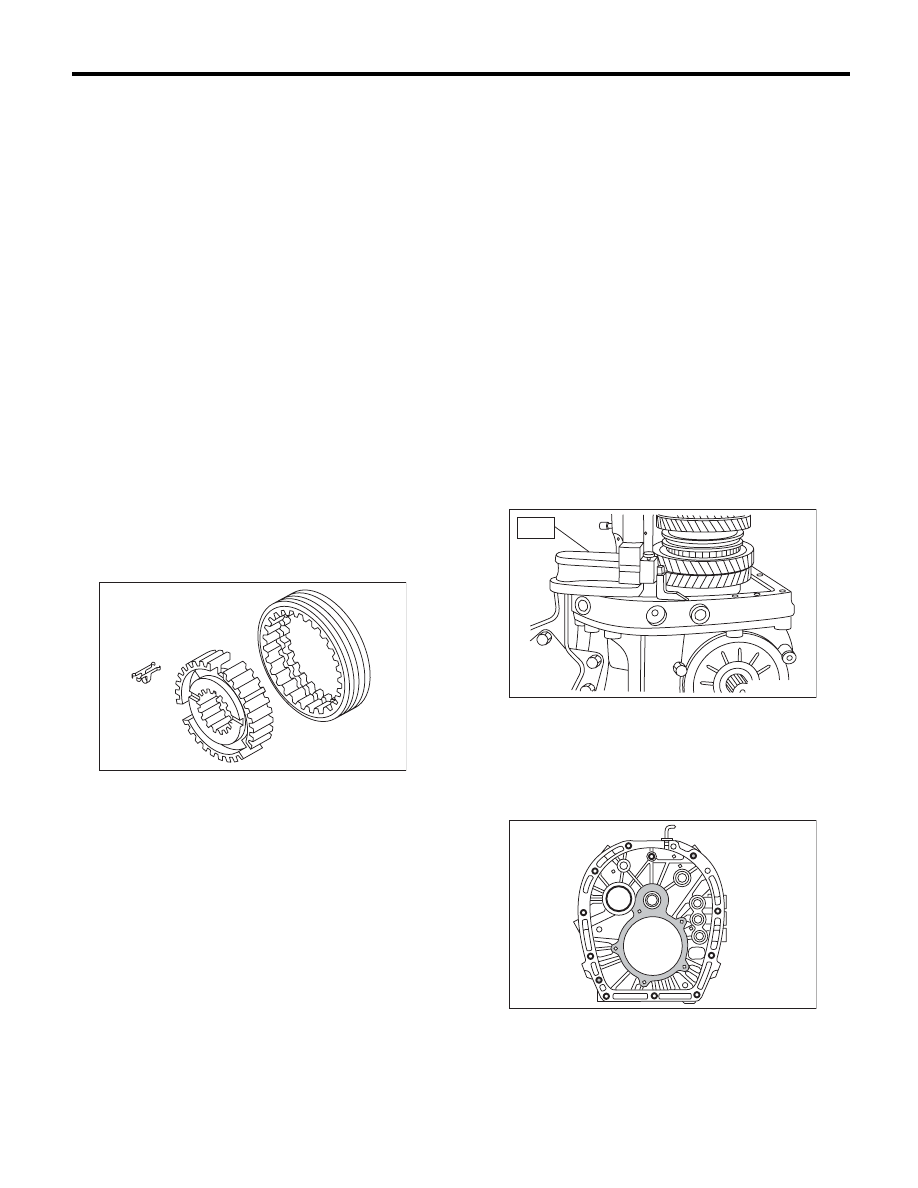

Main Shaft Assembly

MANUAL TRANSMISSION AND DIFFERENTIAL

E: INSPECTION

Disassembled parts should be washed clean first

with cleaning solvent and then inspected carefully.

1) Bearing

Replace the bearings in the following cases.

• Wear, rusting or damage of the bearings

• The bearing does not rotate smoothly or an ab-

normal noise is emitted when turning.

• The bearing has other defects.

2) Bushing (each gear)

Replace the bushing in following cases.

• The sliding surface is damaged or abnormally

worn.

3) Gear

Replace gears in the following cases.

• The gear teeth surface is damaged or excessive-

ly worn.

• The contact area of the baulk ring is damaged.

• The inner face of the gear is worn.

4) Baulk ring, synchro cone

Replace the baulk ring and synchro cone in the fol-

lowing cases.

• Wear, rusting or damage of the baulk ring

5) Shifting insert key

Replace the shifting insert key if deformed, exces-

sively worn or defective in any way.

F: ADJUSTMENT

1. MAIN SHAFT SNAP RING & WASHER

SELECTION

NOTE:

In the following conditions, perform the procedures

below.

• Replacing driven gears 1st through 6th

• Replacing the 1st and 2nd synchro ring assem-

bly

• Replacing the ball bearing

• Replacing the adapter plate

• Replacing the driven shaft

1) Insert the drive pinion assembly into the adapter

plate.

NOTE:

Confirm that the thrust bearing outer race has not

been removed and the drive pinion is not lifted.

2) Set the height gauge to the adapter plate. Lower

the height gauge indicator to the mating surface of

the adapter plate and case, and set to zero points.

ST

18853AA000

HEIGHT GAUGE

NOTE:

• The adapter plate will be the base point for the

measurement. Use a scraper to remove any gasket

material remaining on the end face.

• During measurement, do not place the height

gauge in the shaded area shown in the figure.

MT-00581

MT-00582

ST

MT-00583