SsangYong Stavic / SsangYong Rodius (2005 year). Service manual - part 107

DI04-21

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

EXHAUST SYSTEM

DI ENG SM - 2004.9

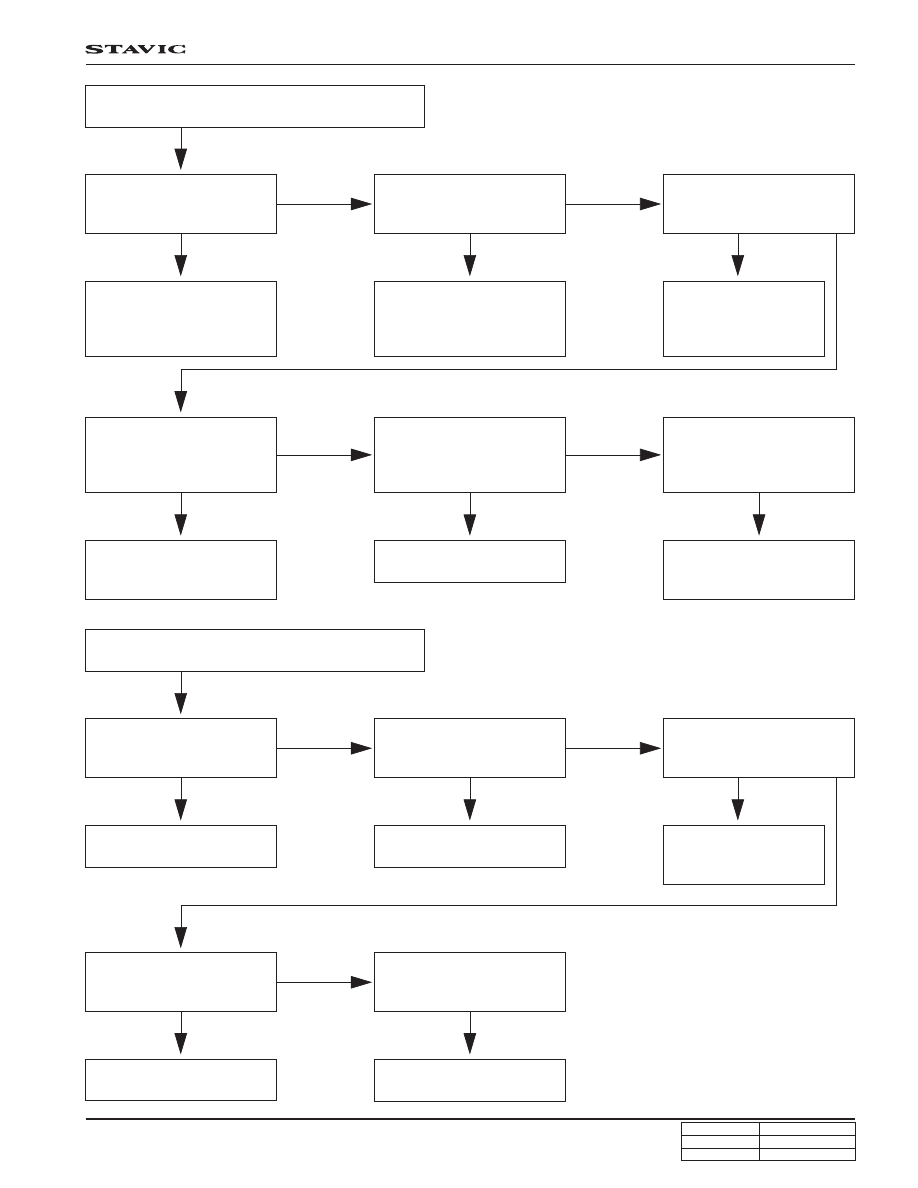

Poor Rotation of the Turbo Charger

Compressor Wheel

Damages By Inflow of

Foreign Material

Turbine Wheel Damages

By Inflow of Foreign

Material

Interference of Compres-

sor Wheel with Housing

NO

NO

YES

YES

YES

Repair or Replace Air

Cleaner Element and

Turbo Charger

Repair or Replace Ex-

haust Manifold

NO

Clogging of Compressor

by Dust

Excessive Deposit of

Carbon or Combustion

Residues Inside of Turbine

Wheel by Oil Contamination

Gel Type Oil in Center

Housing

NO

NO

YES

YES

Repair or Replace Air

Cleaner Element and

Turbo Charger

Repair or Replace Engine

Oil Filter and Turbo

Charger

Excessive Filling of Oil

When Installing

Clogging of Oil Drain

Pipes in Turbo Charger

Gel Type Oil in Center

Housing or Excessively

Contaminated Oil

NO

NO

YES

YES

YES

Oil Disappears After

Combustion

Clean or Replace Drain

Line

Repair or Replace

Engine Oil Filter and

Turbo Charger

NO

Deterioration of Turbo

Charger Journal

Poor Engine Function

(Too High Blow-by gas

pressure in crankcase)

NO

YES

Refer to Diagnosis Table

YES

Inspect PVC Line

YES

Repair or Replace Turbo

Charger

Oil Leakage at Turbine in Turbo Charger

Fatigue and Wear in

Bearing or Shaft

Journal (Refer to

Diagnosis Table)