SsangYong Stavic / SsangYong Rodius (2005 year). Service manual - part 91

DI02-39

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

ENGINE HOUSING

DI ENG SM - 2004.9

Notice

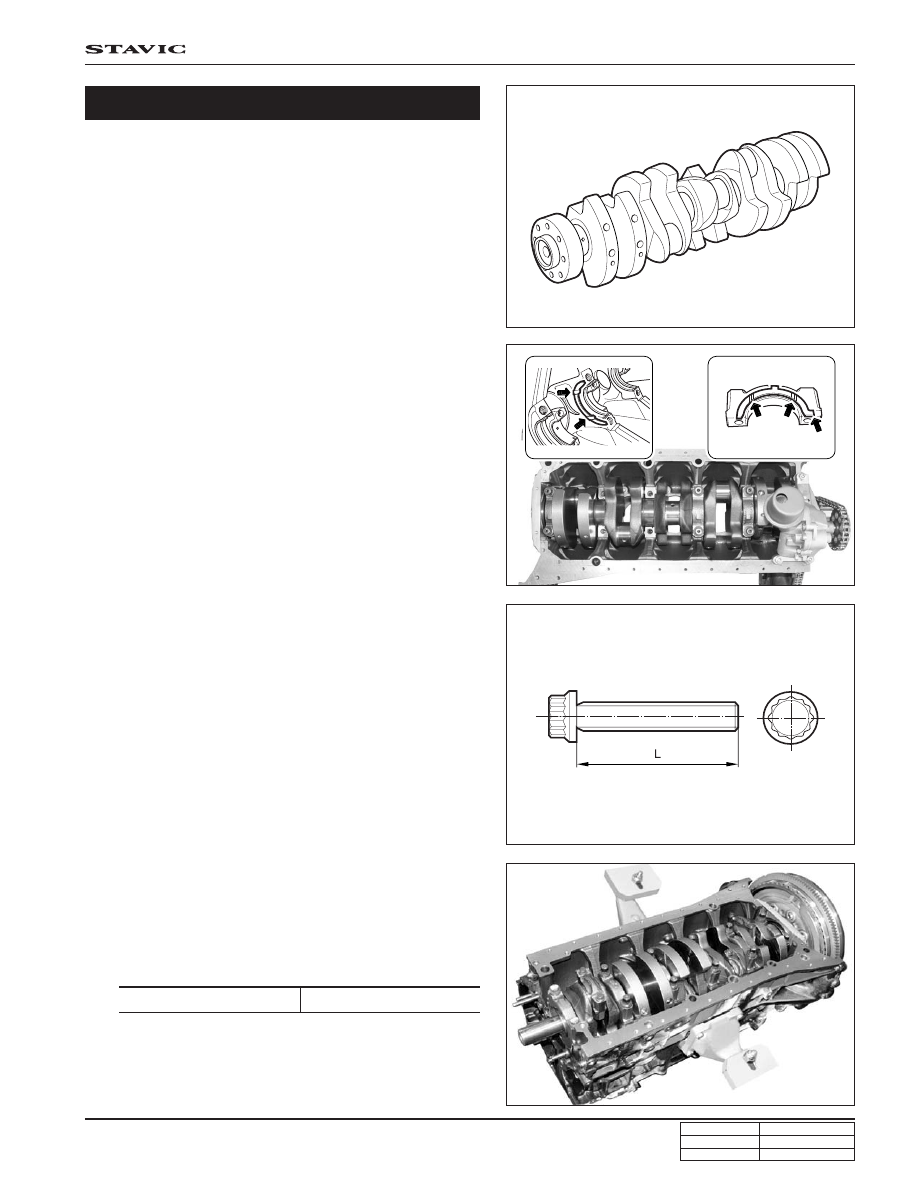

The retaining lugs should be positioned in the grooves

(arrow).

Notice

If the maximum permissible length of L= 63.8 mm is

exceeded, the 12-sided stretch bolts should be

replaced.

2. Coat the upper thrust washers with oil and insert into the

crankcase so that the oil grooves are facing the crank

webs (arrow).

3. Coat the lower thrust washers with oil and insert into the

crankcase so that the oil grooves are facing the crank

webs (arrow).

1. Thoroughly clean the oil galleries and check the journal

section and bearings. Replace if necessary.

4. Coat the new crankshaft with engine oil and place it on

the crankcase.

5. Install the crankshaft bearing caps according to the

markings and tighten the bolts.

Installation Notice

Tightening torque

55 ± 5 Nm + 90° + 10°

•

Install from #1 cap.

Crankshaft - Reassembly