SsangYong Stavic / SsangYong Rodius (2005 year). Service manual - part 80

DI01-15

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

ENGINE ASSEMBLY

DI ENG SM - 2004.9

Notice

• Before cranking the engine, make sure that the test wiring, tools and persons are keeping away from moving

components of engine (e.g., belt and cooling fan).

• Park the vehicle on the level ground and apply the parking brake.

• Do not allow anybody to be in front of the vehicle.

Specifications

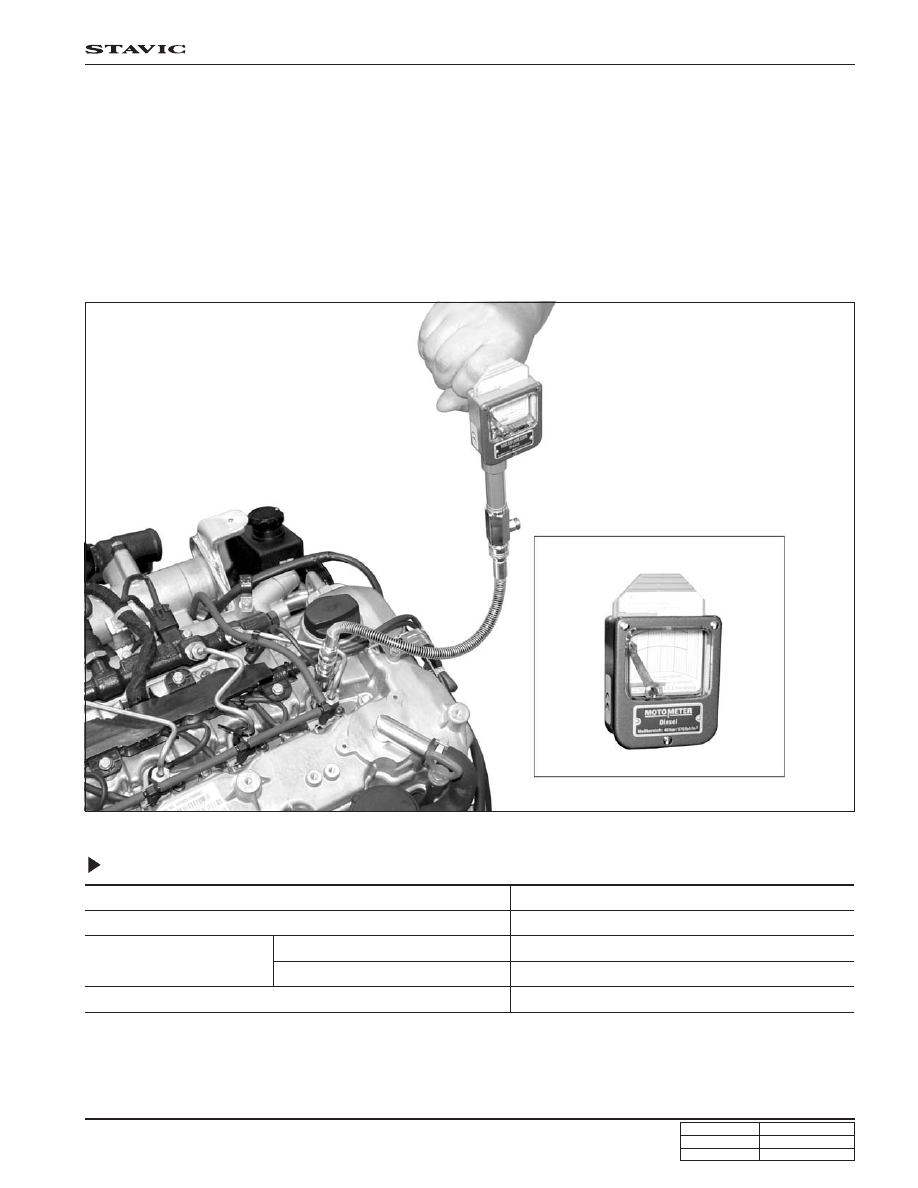

COMPRESSION PRESSURE TEST

The compression pressure test is to check the conditions of internal components (piston, piston ring, intake and

exhaust vale, cylinder head gasket). This test provides current engine operating status.

Compression ratio

Test temperature

Compression pressure

Normal value

Minimum value

Permissible pressure difference between individual cylinders

18 : 1

at normal operating temperature (80°C)

32 bar

18 bar

Max. 3 bar