SsangYong Stavic / SsangYong Rodius (2005 year). Service manual - part 73

DI0A-28

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

DI ENG SM - 2004.9

VEHICLE LIFTING PROCEDURES

To raise the vehicle, place the lifting equipment only at the

points indicated. Failure to use these precise positions

may result in permanent vehicle body deformation.

Many dealer service facilities and service stations are

equipped with automative hoists that bear upon some parts

of the frame in order to lift the vehicle. If any other hoist

method is used, take special care to avoid damaging the

fuel tank, the filter neck, the exhaust system, or the

underbody.

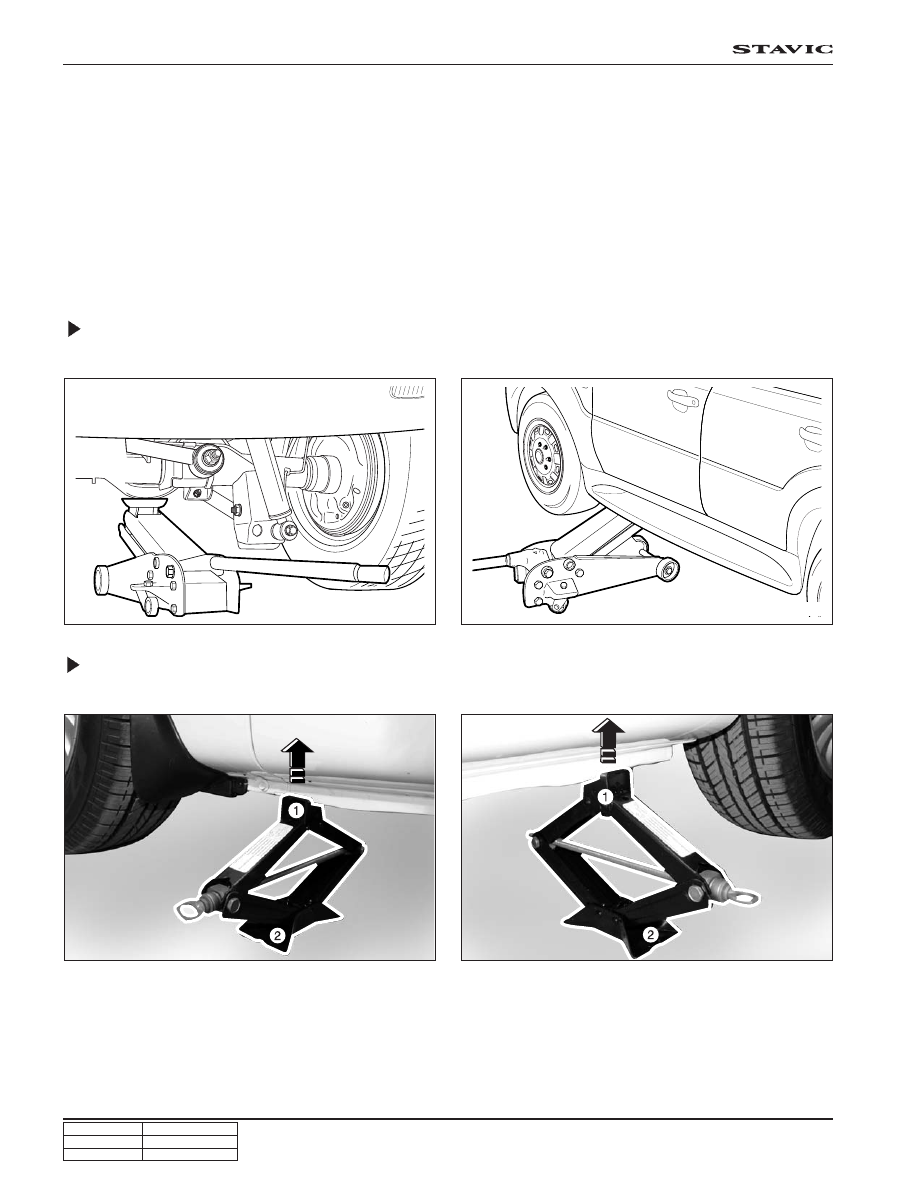

Using Floor Jack

Front Side

Rear Side

Front Jack Up Point

Using Jack

Rear Jack Up Point