SsangYong Stavic / SsangYong Rodius (2005 year). Service manual - part 31

1B-108

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

ENGINE MECHANICAL

M162 GSL ENG SM - 2005.7

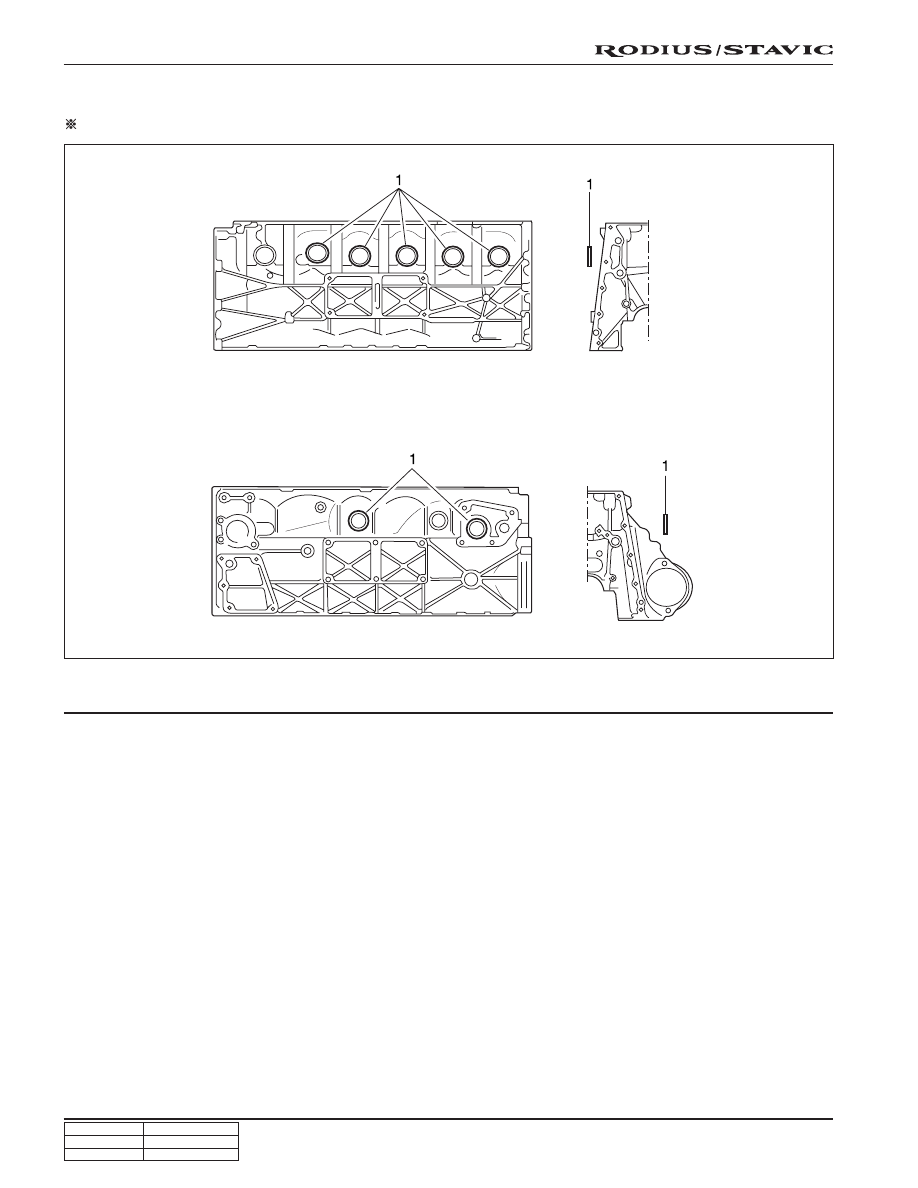

CORE PLUGS IN CRANKCASE

Preceding Work: Draining of the coolant

1. Core plug ................................................... replace