SsangYong Rodius (2013 year). Service manual - part 180

01-14

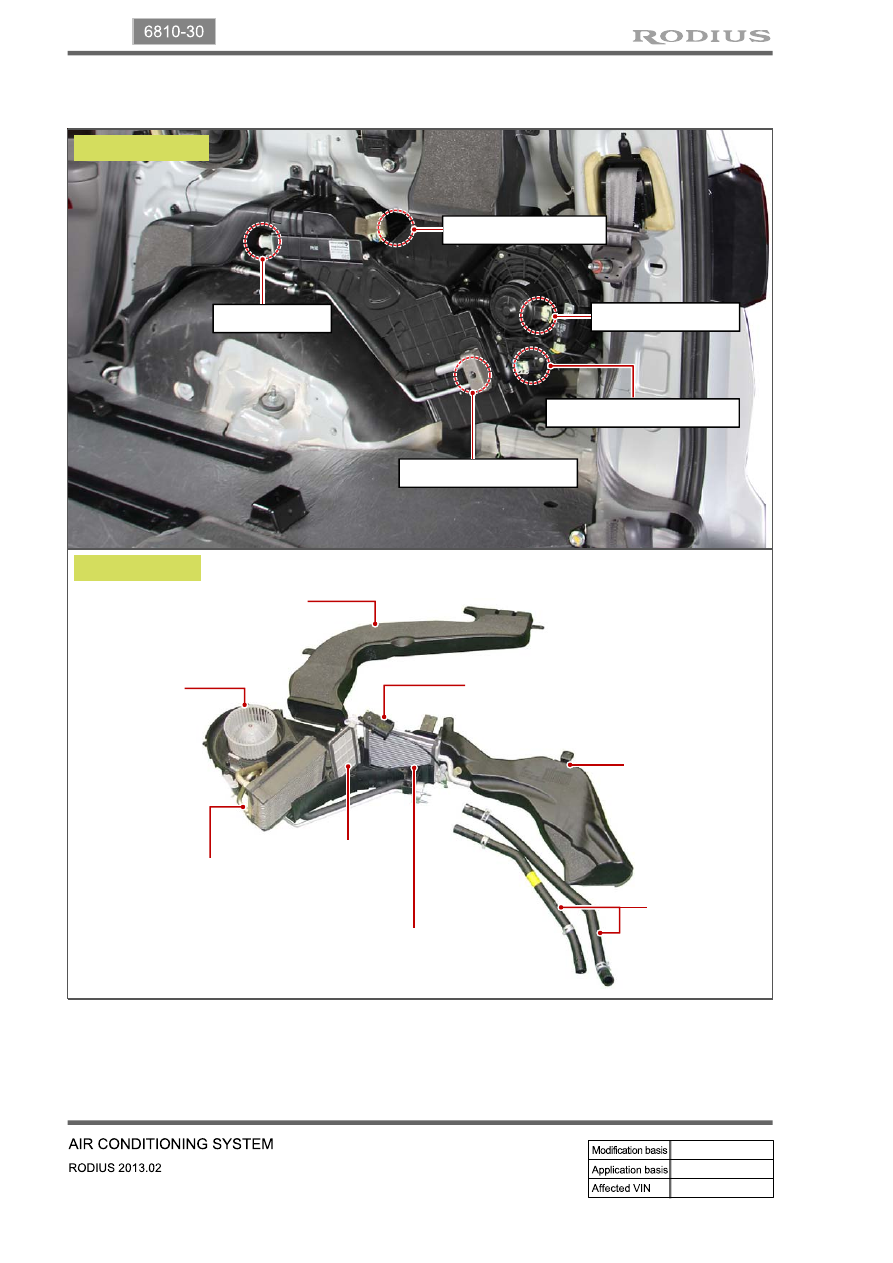

(2) Rear Air Conditioner Module

Roof air conditioner duct

Blower motor

Evaporator

Mixer door

Heater core

Air mixer door actuator

Rear floor

heater duct

Heater &

air conditioner

pipes

Wiring layout

Components

Rear mode actuator

Rear expansion valve

Rear blower motor

Heater valve

Rear blower resistance