Dacia Pick-Up 1304/1305/1307. Service manual - part 21

10

10 - 50

ENGINE AND LOWER ENGINE UNITS

Take out the crankshaft pinion by means of

the MOT 49 device.

Dismount the engine flywhhe.

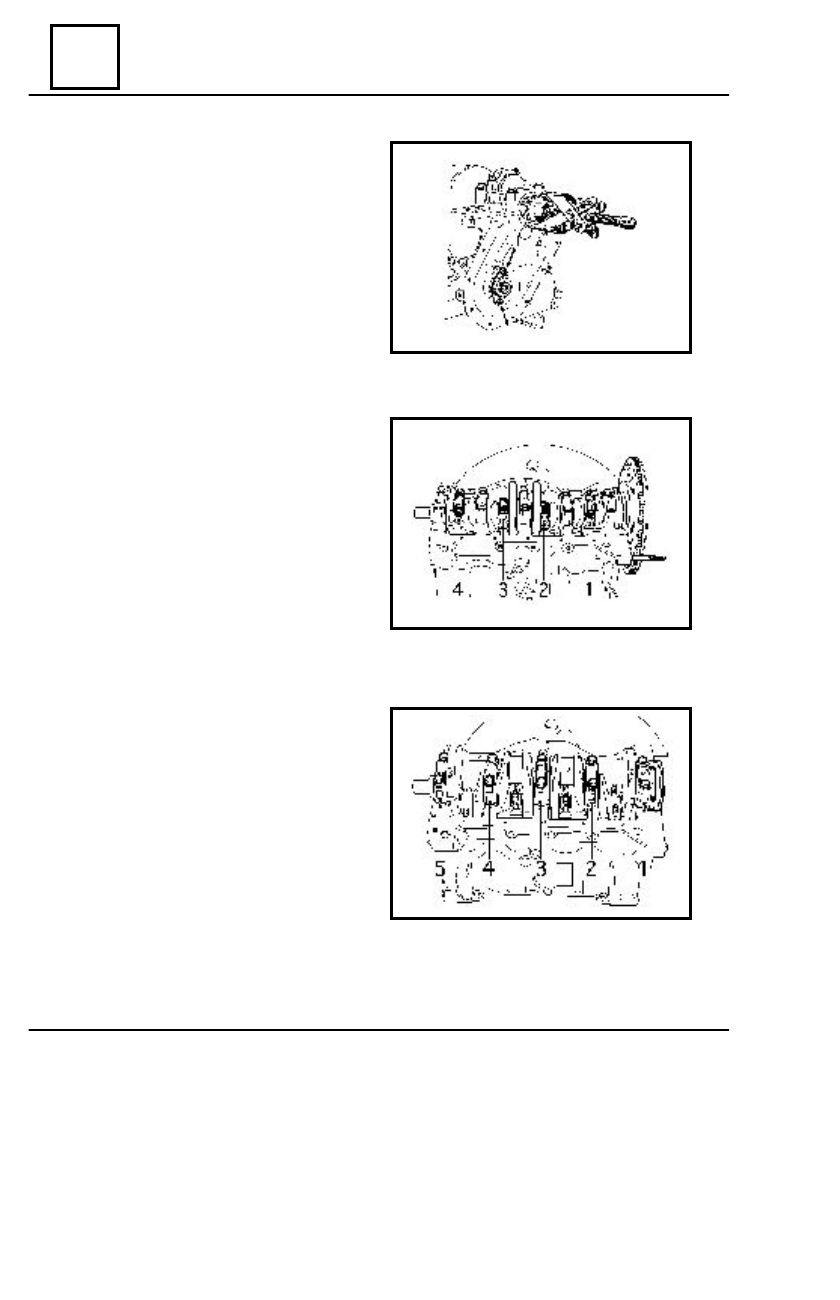

Check the marking of the connecting rods:

- no.1 towards the flywheel and opposite

to the camshaft.

Unscrew the connecting rod caps nuts.

Dismount the connecting rods cas and the half

bushings and place them in order.

Dismount the crankshaft.

Dismount the connecting bearing and the half

bushings and place them in order.

Dismount the crankshaft.

DISMOUNTING - MOUNTING