Dacia Pick-Up 1304/1305/1307. Service manual - part 5

VALUES AND SETTINGS

07

07 - 2

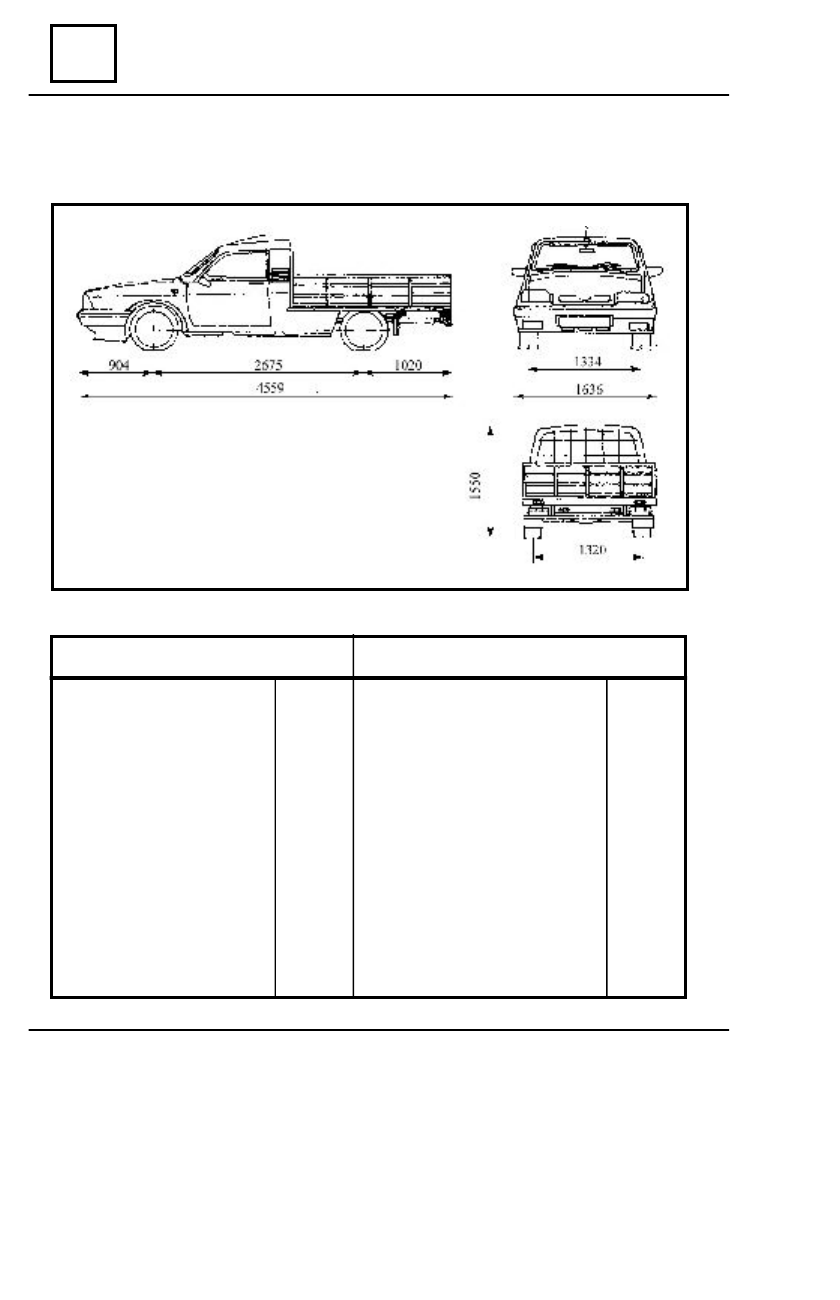

DIMENSIONS

DACIA 1304 PLATFORM

DACIA 1305 PLATFORM

D

IMENSIONS

( mm )

W

EIGHT

( kg )

Total length

Total width

Total height

Empty

Loaded

Axle base

Front wheel track width

Rear wheel track width

Ground clearance

Empty

Loaded

Turn radius

Between footways

Between walls

4599

1615

1550

1450

2675

1334

1320

-

165

5600

5800

595

520

1115

760

1550

2230

1000

3225

2630