Nissan Qashqai (2007-2010). Manual - part 866

HA-34

< ON-VEHICLE MAINTENANCE >

[AUTOMATIC AIR CONDITIONER (HR/MR)]

ELECTRICAL LEAK DETECTOR

2.

Connect a suitable A/C manifold gauge set (SST: J-39183) to the A/C service valves.

3.

Check if the A/C refrigerant pressure is at least 345 kPa (3.52 kg/cm

2

, 50 psi) above 16

°

C (61

°

F). If less

than specification, recover/evacuate and recharge the system with the specified amount of refrigerant.

NOTE:

At temperatures below 16

°

C (61

°

F), leaks may not be detected since the system may not reach 345 kPa

(3.52 kg/cm

2

, 50 psi).

4.

Perform the leak test from the high-pressure side (compressor discharge a to evaporator inlet j) to the

low-pressure side (evaporator drain hose k to shaft seal p). Perform a leak check for the following areas

carefully. Clean the component to be checked and move the leak detected probe completely around the

connection/component.

Compressor

Check the fitting of high- and low-pressure flexible hoses, relief valve and shaft seal.

Condenser

Check the fitting of condenser pipe assembly, high-pressure flexible hose and pipe.

Liquid tank

Check the fitting of radiator & condenser assembly and refrigerant pressure sensor.

Service valves

Check all around the service valves. Ensure service valve caps are secured on the service valves (to pre-

vent leaks).

NOTE:

After removing A/C manifold gauge set from service valves, wipe any residue from valves to prevent any

false readings by leak detector.

Cooling unit (Evaporator)

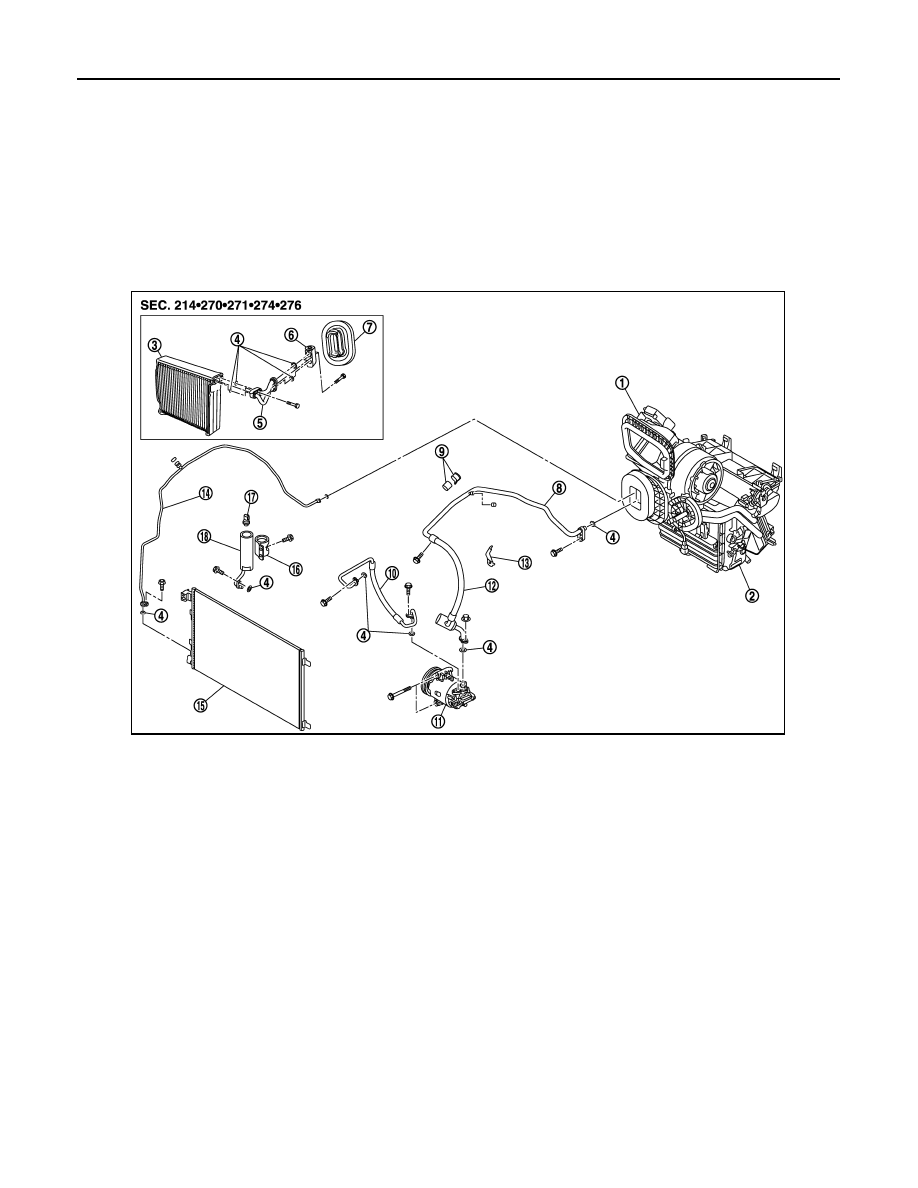

1.

Heater & blower unit assembly

2.

Heater & cooling unit assembly

3.

Evaporator

4.

O-ring

5.

Low pressure pipe 1 and high pres-

sure pipe 2 assembly

6.

Expansion valve

7.

Heater sealing

8.

Low pressure flexible hose and pipe

2

9.

Low pressure pipe 2 fixing clamp as-

sembly

10. High pressure flexible hose

11.

Compressor

12. Low pressure flexible hose

13. Low & high pipe bracket support

14. High pressure pipe 1

15. Condenser assembly

16. Liquid tank fixing bracket

17. Refrigerant pressure sensor

18. Liquid tank

E1KIA0037GB