Nissan Qashqai (2007-2010). Manual - part 697

REAR DISC BRAKE

BR-87

< ON-VEHICLE REPAIR >

[RHD]

C

D

E

G

H

I

J

K

L

M

A

B

BR

N

O

P

BRAKE CALIPER ASSEMBLY : Removal and Installation

INFOID:0000000000938094

REMOVAL

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

1.

Remove tires.

2.

Fix the disc rotor using wheel nuts.

3.

Drain brake fluid. Refer to

CAUTION:

Never spill or splash brake fluid on the disc rotor.

4.

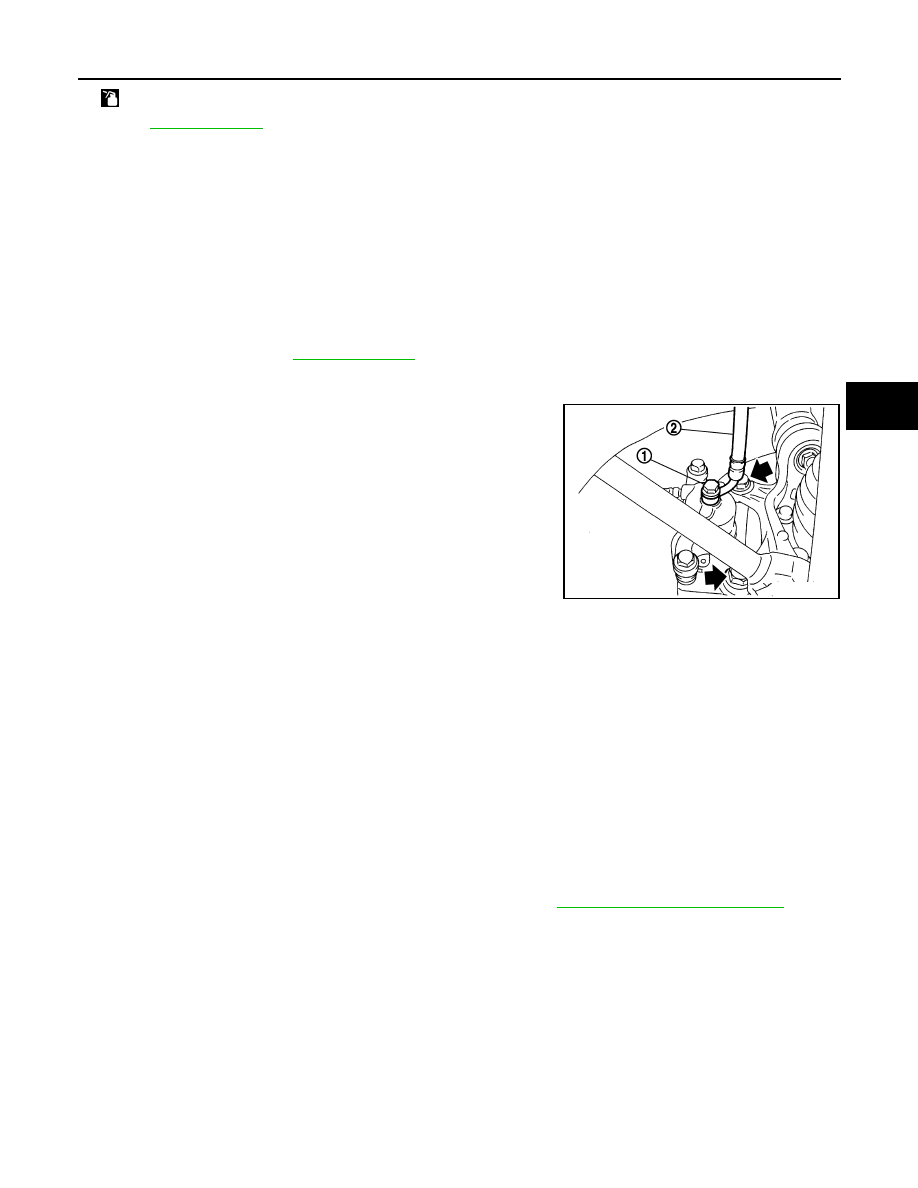

Remove union bolt (1) and then disconnect brake hose (2) from

caliper assembly.

5.

Remove torque member mounting bolts, and remove brake cali-

per assembly.

CAUTION:

Never drop brake pads and caliper assembly.

6.

Remove disc rotor.

CAUTION:

• Put matching marks on the wheel hub and bearing assem-

bly and the disc rotor before removing the disc rotor.

• Never drop disc rotor.

INSTALLATION

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

1.

Install disc rotor.

CAUTION:

Align the matching marks made during removal when reusing the disc rotor.

2.

Install the brake caliper assembly to the vehicle and tighten the torque member mounting bolts to the

specified torque.

CAUTION:

Never spill or splash any grease and moisture on the brake caliper assembly mounting face,

threads, mounting bolts, and washers. Wipe out any grease and moisture.

3.

Install brake hose to brake caliper assembly, and tighten union bolts to the specified torque.

4.

Refill with new brake fluid and perform the air bleeding. Refer to

BR-12, "Bleeding Brake System"

.

CAUTION:

• Never reuse drained brake fluid.

• Never spill or splash brake fluid on the disc rotor.

5.

Check that no drag feel is present for the rear disc brake.

6.

Install tires.

BRAKE CALIPER ASSEMBLY : Disassembly and Assembly

INFOID:0000000000938095

DISASSEMBLY

NOTE:

Never remove the torque member, brake pads, shims, shim cover and pad retainers disassembling and

assembling the cylinder body.

: Apply brake fluid.

Refer to

for symbols not described on the above.

JPFIA0036ZZ