Nissan Qashqai (2007-2010). Manual - part 640

ELECTRIC CONTROLLED COUPLING

DLN-133

< DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R145]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

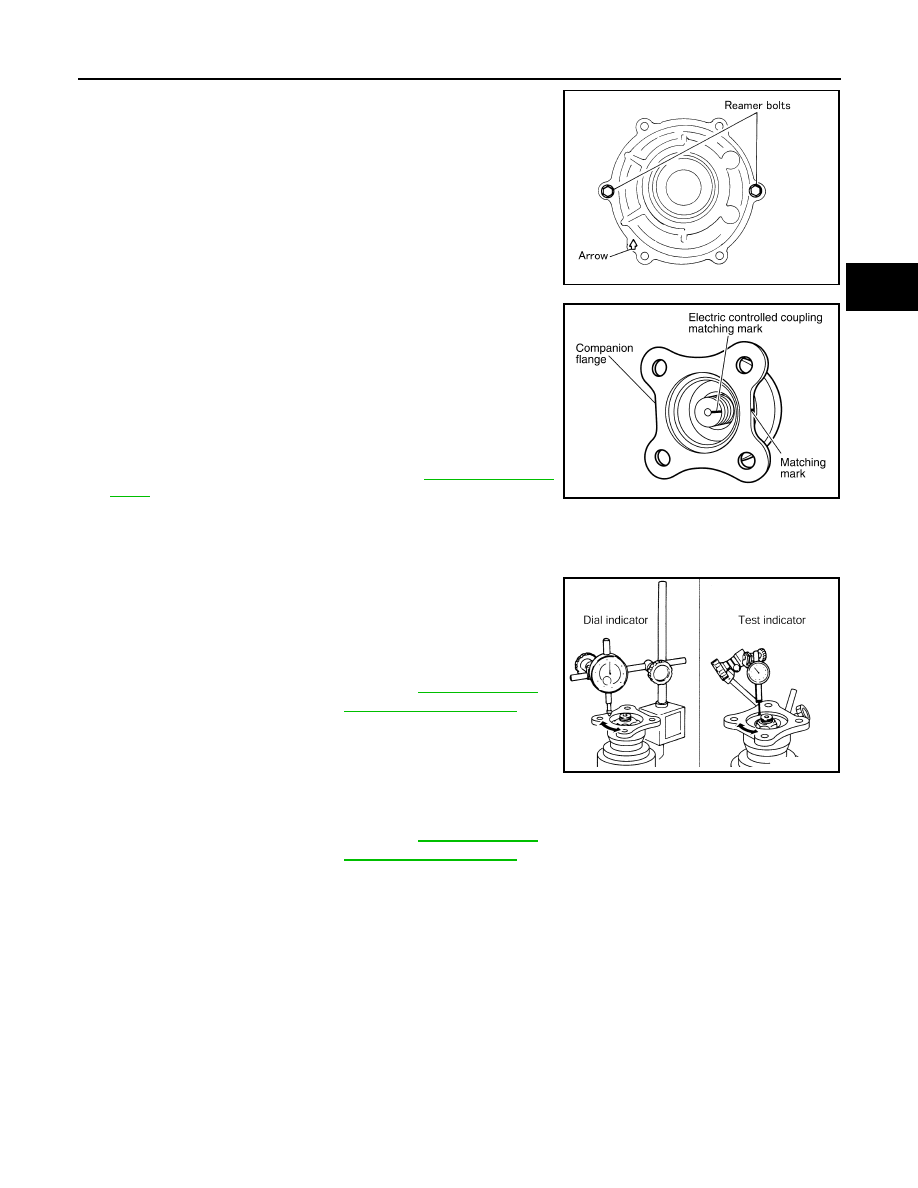

8.

Install coupling cover to gear carrier with arrow facing upward,

temporarily tighten reamer bolts to the positions shown in the

figure.

9.

Tighten reamer bolts and coupling cover mounting bolts to the

specified torque.

10. Install connector bracket, and tighten bolts to the specified

torque.

11. Install companion flange.

NOTE:

When reusing electric controlled coupling, align the matching

mark of electric controlled coupling with the matching mark of

companion flange, then install companion flange.

12. Install companion flange lock nut with flange wrench (commer-

cial service tool), tighten to the specified torque.

CAUTION:

Never reuse companion flange lock nut.

13. Check companion flange runout. Refer to

.

Adjustment

INFOID:0000000000972187

COMPANION FLANGE RUNOUT

1.

Fit a dial indicator onto the companion flange face (inner side of

the rear propeller shaft mounting bolt holes).

2.

Rotate companion flange to check for runout.

3.

Fit a test indicator to the inner side of companion flange (socket

diameter).

4.

Rotate companion flange to check for runout.

5.

If the runout value is outside the runout limit, follow the procedure below to adjust.

a.

Check for runout while changing the phase between companion flange and drive pinion by 90

°

step, and

search for the position where the runout is the minimum.

b.

If the runout value is still outside of the limit after the phase has been changed, replace companion flange.

c.

If the runout value is still outside of the limit after companion flange has been replaced, possible cause will

be an assembly malfunction of drive pinion and electric controlled coupling, malfunctioning coupling bear-

ing, or malfunctioning of electric controlled coupling.

Inspection After Disassembly

INFOID:0000000001077000

Clean up the disassembled parts. Then, inspect if the parts are worn or damaged. If so, follow the measures

below.

SDIA0587E

PDIA0455E

Limit

Companion flange runout

: Refer to

.

Limit

Companion flange runout

: Refer to

.

PDIA0439E