Nissan Qashqai (2007-2010). Manual - part 628

DRIVE PINION

DLN-85

< DISASSEMBLY AND ASSEMBLY >

[TRANSFER: TY30A]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

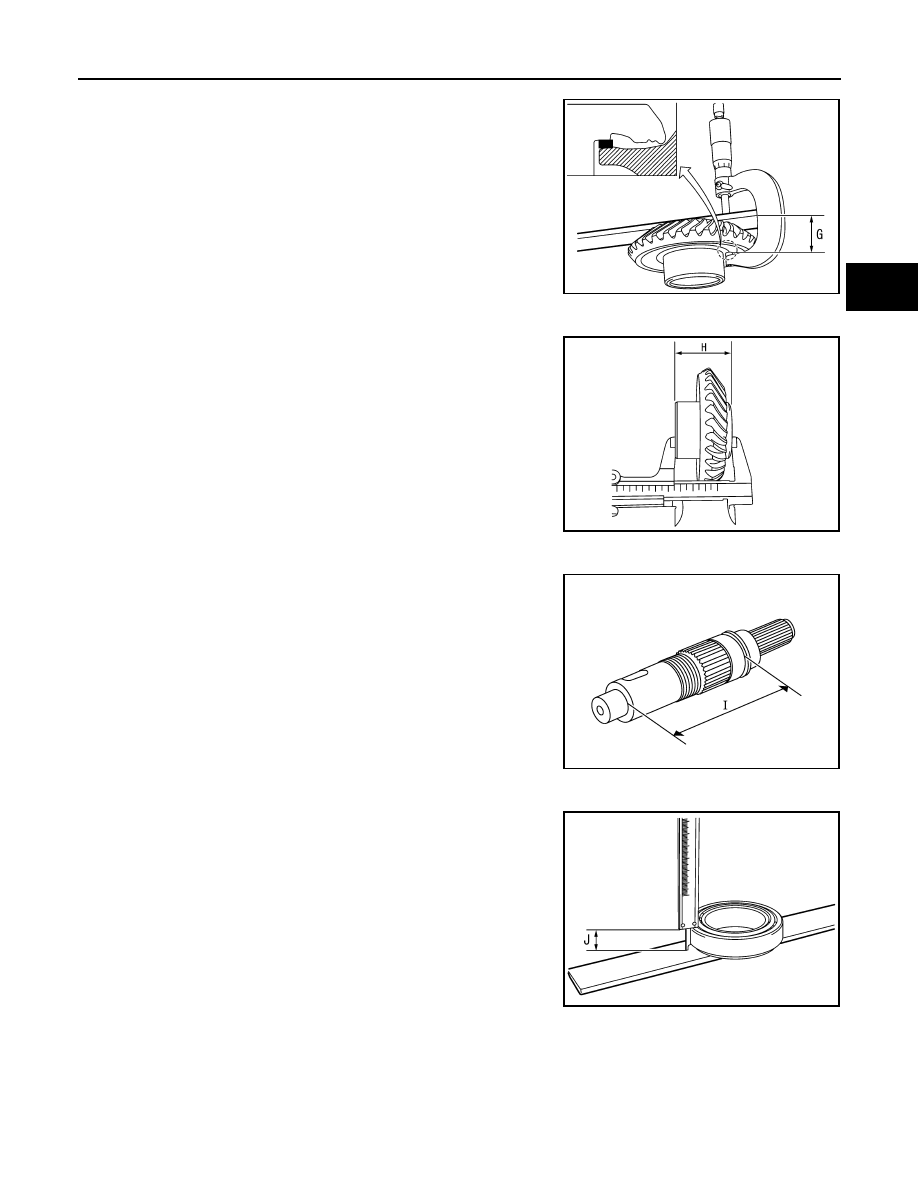

Dimension “G” measurement

• Measure dimension from ring gear shaft bearing mounting sur-

face of ring gear to transfer case side edge surface with a

micrometer and straightedge. Refer to “Measuring point”.

CAUTION:

Consider the thickness of a straightedge.

Dimension “H” measurement

• Measure dimension from transfer case side edge surface of

ring gear to adapter case side edge surface with a pair of ver-

nier calipers. Refer to “Measuring point”.

Dimension “I” measurement

• Measure dimension from ring gear mounting surface of ring

gear shaft to ring gear shaft bearing (transfer case side)

mounting surface with a pair of vernier calipers. Refer to “Mea-

suring point”.

Dimension “J” measurement

• Measure dimension from outer race edge surface of ring gear

shaft bearing (transfer case side) to inner race edge surface

with a pair of vernier calipers. Refer to “Measuring point”.

2.

Calculate dimension “N” by the formula below.

3.

Convert the dimensions “F”, “G”, “H”, “I”, “J” and “N” according to the standards below.

SDIA3111J

SDIA3112J

JSDIA0257ZZ

SDIA3128J

Dimension “N” = “C”

×

0.5 mm (0.020 in) + “D”