Nissan Qashqai (2007-2010). Manual - part 538

TRANSAXLE ASSEMBLY

TM-87

< DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F94R]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

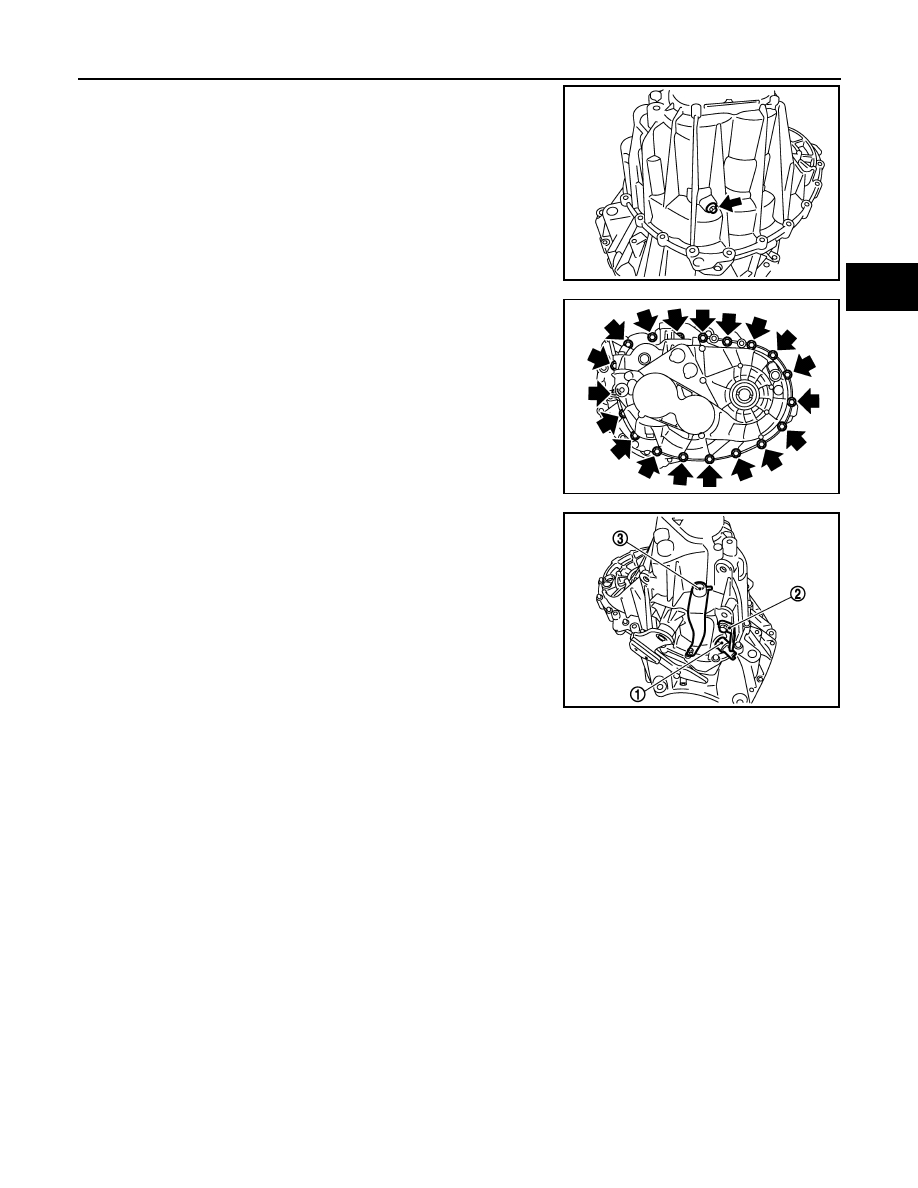

30. Install seal washer and reverse idler shaft mounting bolt, and

then tighten mounting bolt to the specified torque.

CAUTION:

Never reuse seal washer.

31. Tighten mounting bolts to the specified torque.

32. Apply recommended sealant to threads of position switch (1).

Then install it to transaxle case and tighten to the specified

torque.

• Use Genuine Liquid Gasket, Three Bond 1215 or an equiv-

alent.

33. Install bracket (2), and then mounting bolt to the specified

torque.

34. Install shifter lever (3), and then install retaining pin using a pin

punch.

CAUTION:

Never reuse retaining pin.

35. Install gasket onto drain plug, and then install it into clutch hous-

ing using the socket [Commercial service tool]. Tighten drain plug to the specified torque.

CAUTION:

Never reuse gasket.

36. Install gasket onto filler plug, and then install it into transaxle case. Tighten filler plug to the specified

torque.

CAUTION:

• Never reuse gasket.

• After gear oil is filled, tighten filler plug to specified torque.

PCIB1695E

PCIB1694E

SCIA7784E