Content .. 1691 1692 1693 1694 ..

Nissan Qashqai (2007-2010). Manual - part 1693

LAN

ECM BRANCH LINE CIRCUIT

LAN-797

< COMPONENT DIAGNOSIS >

[CAN SYSTEM (TYPE 53)]

C

D

E

F

G

H

I

J

K

L

B

A

O

P

N

ECM BRANCH LINE CIRCUIT

Diagnosis Procedure

INFOID:0000000001057026

1.

CHECK CONNECTOR

1.

Turn the ignition switch OFF.

2.

Disconnect the battery cable from the negative terminal.

3.

Check the terminals and connectors of the ECM for damage, bend and loose connection (unit side and

connector side).

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair the terminal and connector.

2.

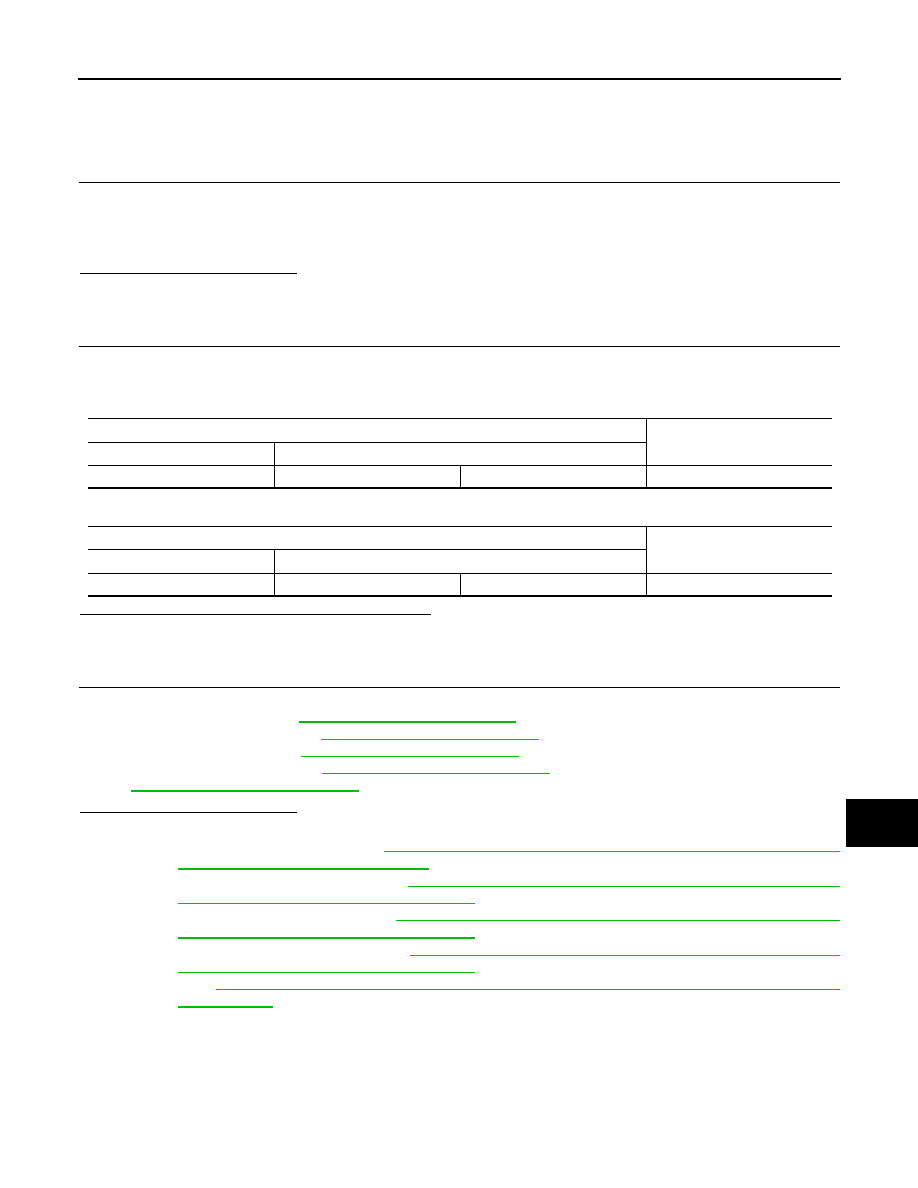

CHECK HARNESS FOR OPEN CIRCUIT

1.

Disconnect the connector of ECM.

2.

Check the resistance between the ECM harness connector terminals.

-

HR engine/MR engine models

-

K9K engine models

Is the measurement value within the specification?

YES

>> GO TO 3.

NO

>> Repair the ECM branch line.

3.

CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the ECM. Refer to the following.

• HR16DE (With EURO-OBD):

• HR16DE (Without EURO-OBD):

• MR20DE (With EURO-OBD):

• MR20DE (Without EURO-OBD):

EC-1069, "Diagnosis Procedure"

EC-1317, "Diagnosis Procedure"

Is the inspection result normal?

YES (Present error)>>•Replace the ECM. Refer to the following.

- HR16DE (With EURO-OBD):

EC-29, "ADDITIONAL SERVICE WHEN REPLACING CONTROL

UNIT : Special Repair Requirement"

EC-368, "ADDITIONAL SERVICE WHEN REPLACING CON-

TROL UNIT : Special Repair Requirement"

- MR20DE (With EURO-OBD):

EC-645, "ADDITIONAL SERVICE WHEN REPLACING CON-

TROL UNIT : Special Repair Requirement"

- MR20DE (Without EURO-OBD):

EC-989, "ADDITIONAL SERVICE WHEN REPLACING CON-

TROL UNIT : Special Repair Requirement"

EC-1273, "ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair

YES (Past error)>>Error was detected in the ECM branch line.

NO

>> Repair the power supply and the ground circuit.

ECM harness connector

Resistance (

Ω

)

Connector No.

Terminal No.

E16

84

83

Approx. 108 – 132

ECM harness connector

Resistance (

Ω

)

Connector No.

Terminal No.

E60

100

99

Approx. 108 – 132