Jaguar XJ-S. Service manual - part 95

375

Besides providing lousy response when new, the OEM mounts are also known for a lack of durability, and of course

when they come apart they come apart all at once. Ray Johnson says, “everything was fine and then the next thing I

knew I was tacking a 4200# sailboat down the highway.”

On the XJ-S discussion list on the Internet, this author mentioned the possibility that this inconsistent response might

actually be dangerous, especially with drivers that never drive hard and therefore are taken by surprise in the first panic

situation they encounter. Of course, the first panic situation may rip the mounts apart -- but do you really care exactly

why the mounts don’t work right in the first panic situation? Jim Downes responded: “Many (too many) moons ago

when I was a student, I worked part-time at a Jag/Rolls dealership in Ireland. Occasionally, a customer's Jag would be

towed in after a very bad crash. Most customers complained of an apparent loss of directional control during (as Kirby

correctly identifies) a 'panic' situation. In almost every case, the bushings were worn and behaved exactly as described

above. Absolutely all of the senior mechanics there felt that the bushings were dangerous after a few months of use.”

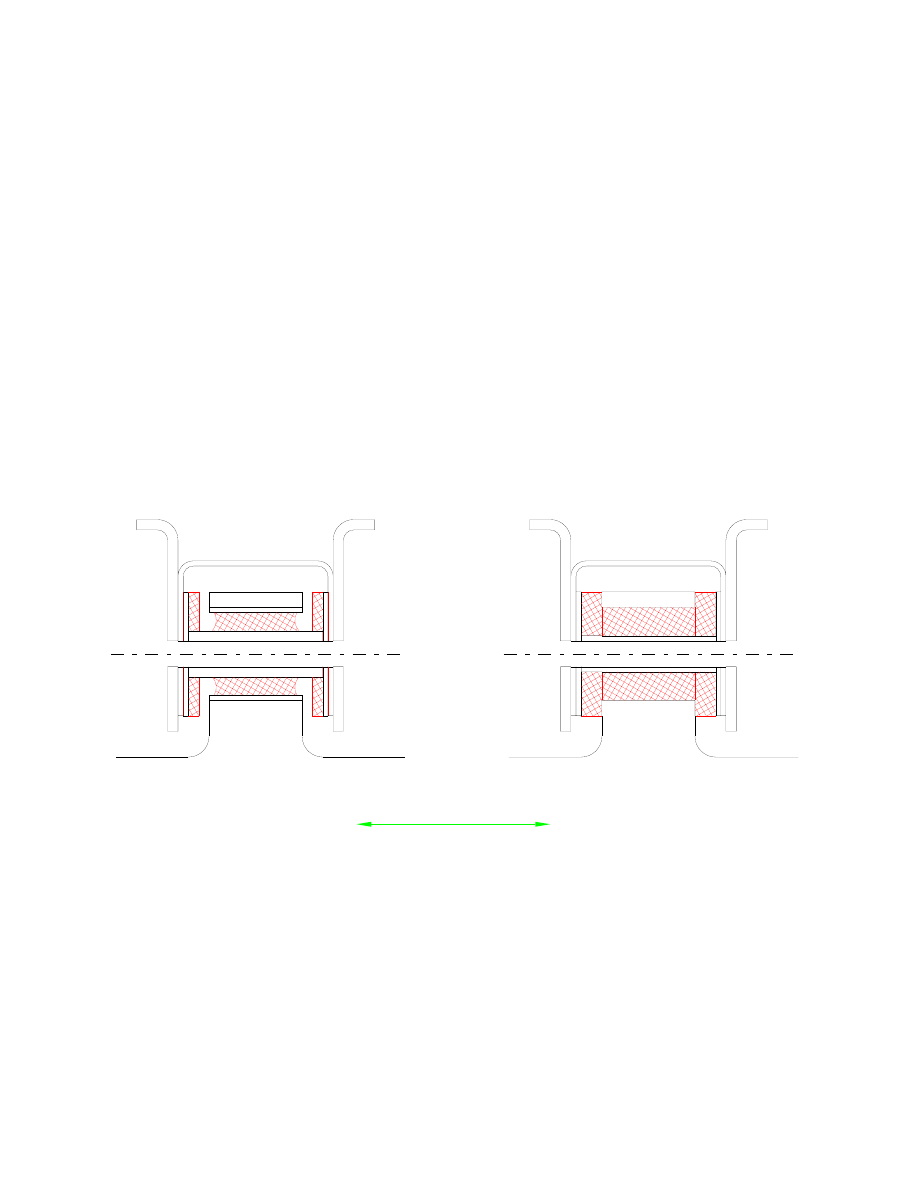

The solution is to replace the steering rack mount bushings with ones that are not merely stiffer but of a totally different

design. This modification is so common that virtually every aftermarket business dealing in Jaguar stuff offers a kit.

The John’s Cars design (see page 715) subjects the elastomers to compression only, and eliminates the inconsistency in

the steering response. They use polyurethane, making the mounts stiff but not totally rigid. The entire kit is about $50,

and well worth the money. A similar kit is the Mackay Sure Trak A1598U, available from BPI (see page 689). XK’s

unlimited (see page 694) offers a kit of slightly different design made of delrin, but the function is similar.

Folks, please take this recommendation seriously: even if the stock bushings have not yet failed, even if they are brand

new, replace them with aftermarket bushings as soon as possible. If you are determined to keep your car “original”,

please yank those original junk bushings out and carefully box them away for future concours events, and install some

good mounts for any actual driving you may do. Downes concurs: “Regardless of perceived 'quality' of feel, when I

move the wheel expecting a twenty degree turn, that's what I want, not fifteen or twenty five degrees depending on

side-loads, braking loads, road camber or any of the other variables that can influence the 'mood' of the original

bushings.”

STOCK

BUSHING

AFTERMARKET

BUSHING

DIRECTION OF

STEERING FORCES

Figure 18 - Original vs. Aftermarket Steering Rack Mounts