Jaguar XJ-S. Service manual - part 29

111

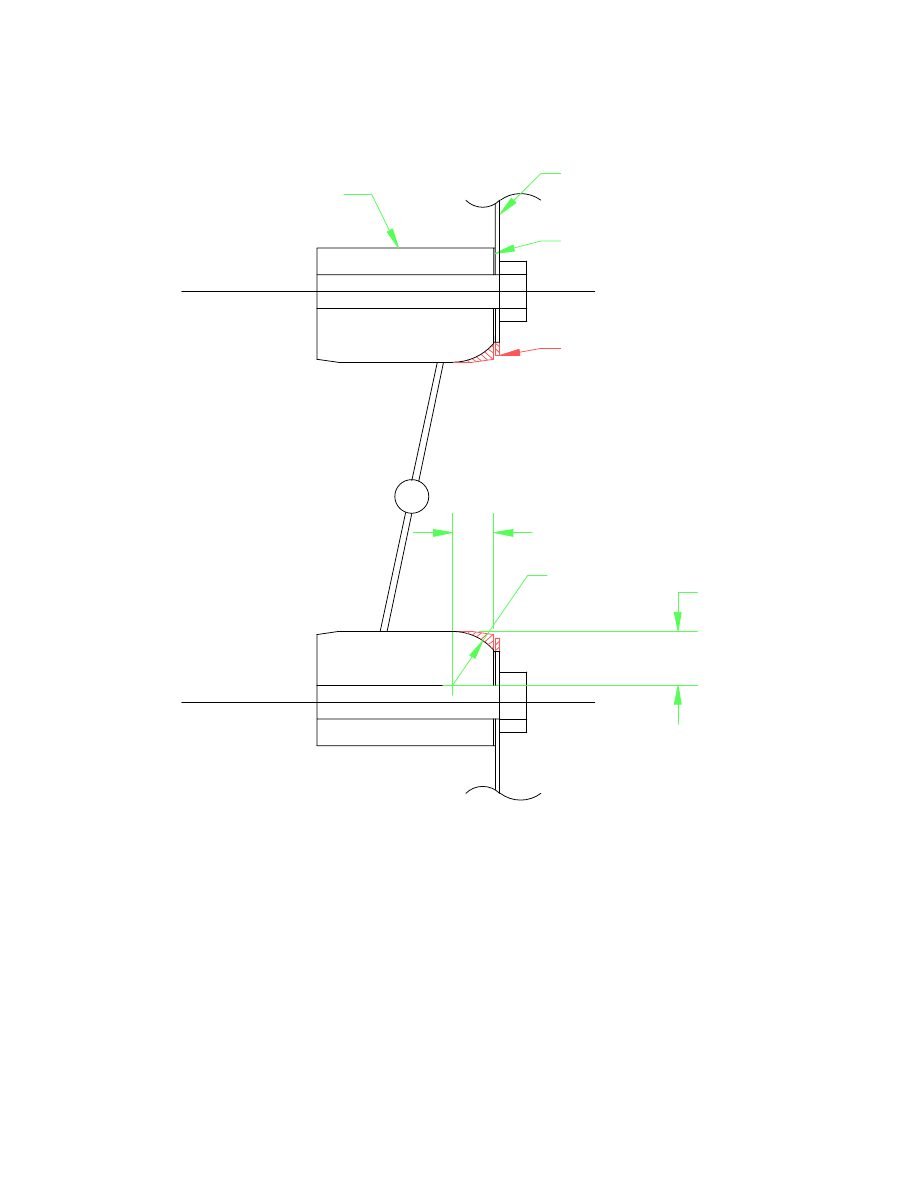

Enlarge the opening in the air filter housing to 2-13/16”. The gaskets typically are already this size, but final trimming

can be done after assembly by using a razor knife before installing the filter.

This modification has not yet been tried, so performance improvements are unquantified. In theory, this mod can

provide an airflow improvement (and hence a horsepower increase) of several percent. Considering the proximity of

the blanked-off section of the air filter, the improvement may be even more significant. There should be no change in

R1/2"

3/8"

1/2"

REMOVE MAT'L

AS SHOWN

GASKET

AIR FILTER

HOUSING

BUTTERFLY

HOUSING

Figure 8 - Butterfly Housing Airflow Improvement