Ford Orion. Manual - part 60

36.6 Long centre console retaining nut

and screw locations (arrowed) - automatic

transmission console shown

35 Facia -

removal and refitting

4

Warning: On vehicles fitted with a

passenger’s air bag, seek the

advice of a Ford dealer

concerning safety implications when

removing the facia assembly.

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5, Section 1).

2 Refer to Chapter 10 for details, and remove

the steering wheel.

3 Undo the two upper and four lower

retaining screws, and remove the upper and

lower steering column shrouds.

4 Refer to the appropriate Chapters

concerned for details, and remove the

following facia-associated items:

a)

Steering column multi-function switch

(Chapter 12).

b)

Instrument panel (Chapter 12).

c)

Choke cable (Chapter 4).

d)

Heating/ventilation controls and control

panel (Chapter 3).

e)

Cigar lighter and ashtray (Chapter 12).

f)

Radio/cassette player (Chapter 12).

g)

Clock (Chapter 12).

5 Undo the two retaining screws, and remove

the side vent panel from the facia on the

driver’s side. As it is withdrawn, disconnect

any wiring connections from the panel-

mounted switches (see illustration).

6 Undo the two hinge/retaining screws

securing the glovebox lid, and remove it. Undo

the two catch screws, and remove the lock/

catch. As the catch is withdrawn, disconnect

the bulbholder/switch wiring connector.

7 Where fitted, detach and remove the

footwell lights from the driver and passenger

side lower facia (Chapter 12).

8 Pull free the weatherstrip from the leading

edge of the door aperture each side to gain

access to the outboard mounting screws.

Unscrew and remove the retaining screws

from the points indicated (see illustrations).

9 Withdraw the facia from its mounting. As it

is withdrawn, note the routing of the cables

attached to the facia, then detach the

cable ties and remove the facia from the

vehicle.

10 The associated components of the facia

can (if required) be detached by undoing the

appropriate retaining screws.

Refitting

11 Refitting is a reversal of the removal

procedure. Ensure that all wiring and cables

are correctly routed and securely

reconnected. Refer to the appropriate

Chapters for details on refitting the associated

fittings to the facia panel.

12 When the facia panel is completely refitted,

reconnect the battery then test the various

facia and steering column switches to ensure

that they operate in a satisfactory manner.

36 Centre console -

removal and refitting

1

Removal

Short console (manual transmission)

1 Unscrew and remove the knob from the

gear lever, then prise free the lever gaiter and

bezel. Slide the gaiter and bezel up the lever,

and lift them off.

2 Unscrew the four retaining screws, and

remove the console (see illustration).

Long console (manual and automatic

transmission)

3 On manual transmission models, Unscrew

and remove the knob from the gear lever, then

prise free the lever gaiter and bezel. Slide the

gaiter and bezel up the lever, and lift them off.

4 On automatic transmission models, select

“P” (Park). Unscrew and remove the knob

from the lever, then prise free the lever

indicator panel, followed by the bezel (see

illustration).

5 On vehicles with electric windows or an

electrically-operated luggage compartment

lock, carefully prise out the switch panel or

switch, and disconnect the wiring connectors.

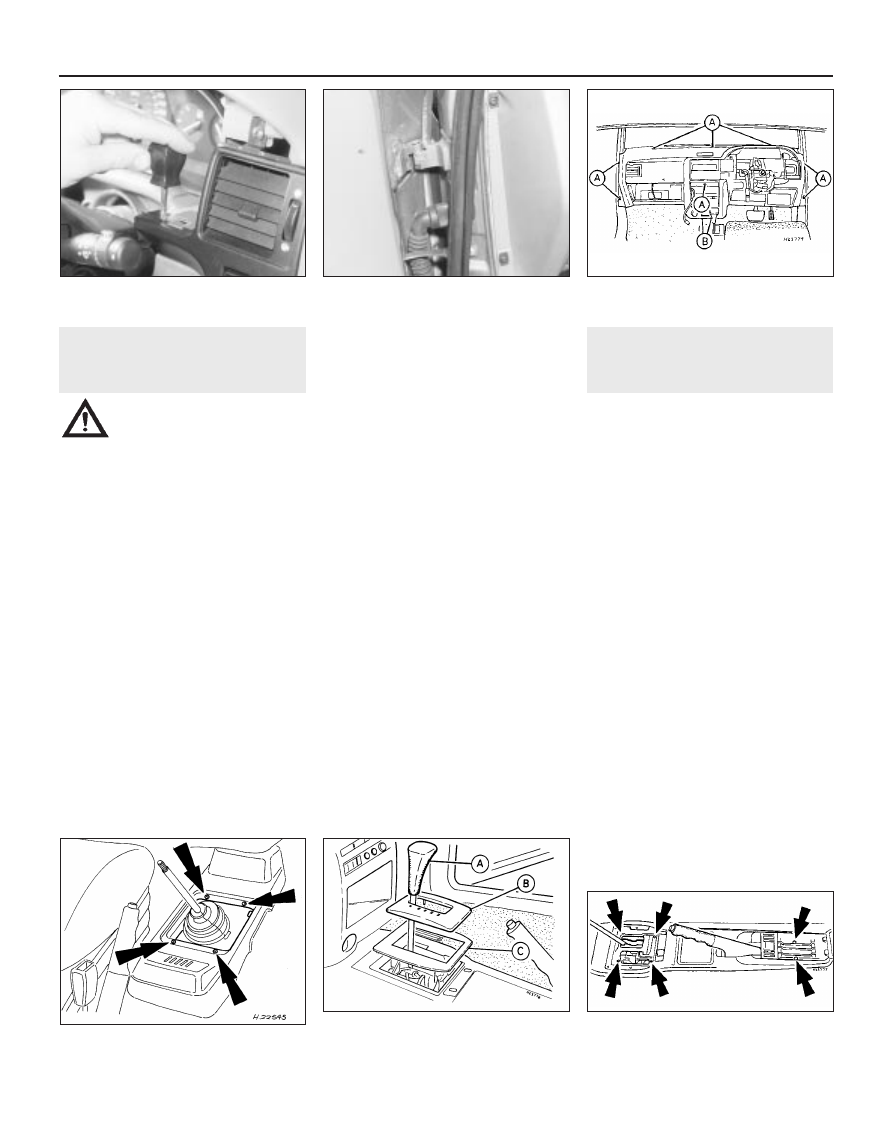

6 Undo the four console retaining nuts and

two screws (see illustration).

7 Pull up the handbrake lever as far as

possible, and manipulate the console over the

handbrake lever and gear lever. If insufficient

clearance exists, slacken the handbrake

adjuster as described in Chapter 1.

11•20 Bodywork and fittings

36.4 Automatic transmission selector

lever knob (A), lever indicator panel (B) and

panel bezel (C)

36.2 Short centre console retaining screw

locations (arrowed)

35.8B Facia retaining screw locations “A”

(screw only) and “B” (screw and washers)

35.8A Pull free the weatherstrip for access

to the outboard facia screws

35.5 Side vent panel removal on the

driver’s side