Daewoo Korando. Service manual - part 260

AUTOMATIC TRANSMISSION 5A-83

Tightening Torque

70 - 80 Nm

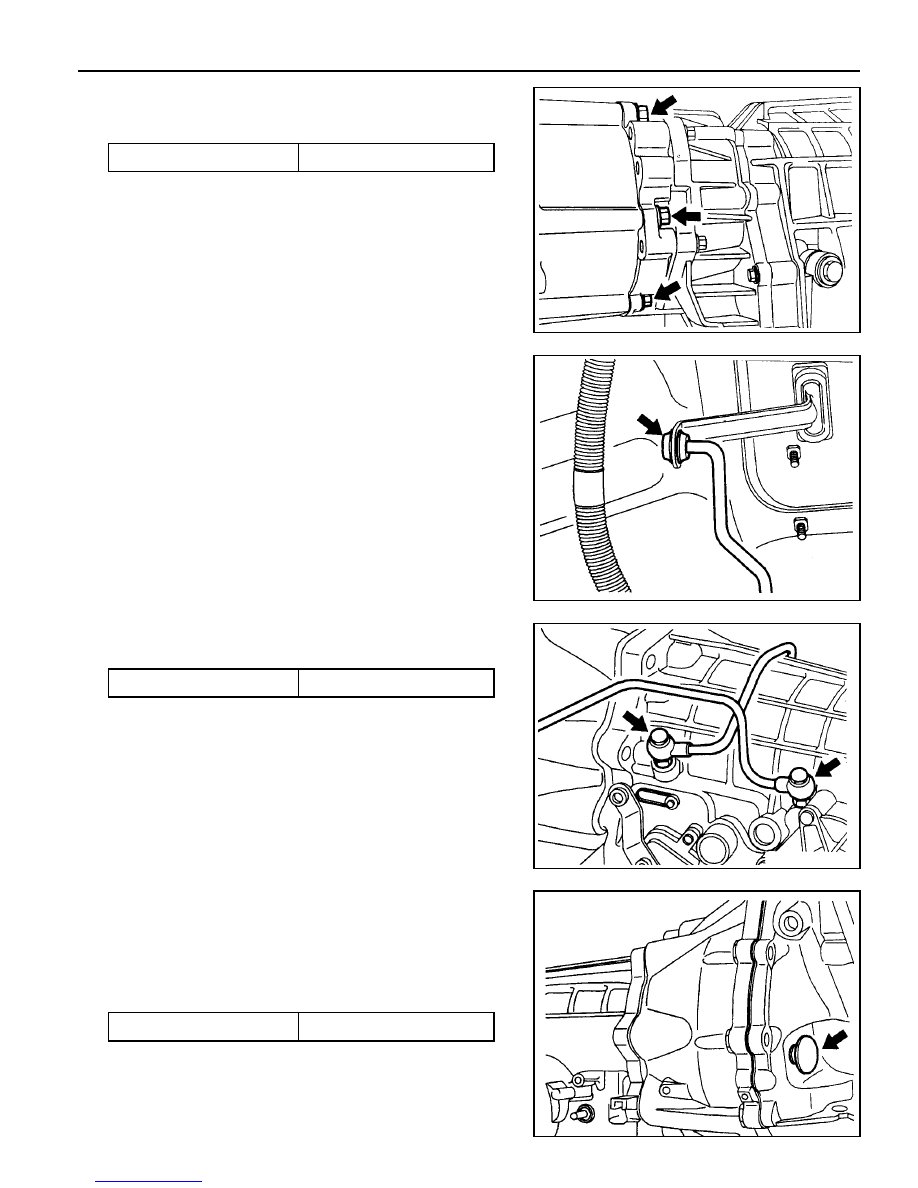

11. Remove the two pipes for oil cooler.

Installation Notice

Tightening Torque

24.5 - 34.3 Nm

12. Remove the service hall cover on torque converter.

13. Put the alignment mark for installation, and unscrew the

six mounting bolts for torque converter from drive plate

through the service hole (arrow) by rotating the engine

and remove the torque converter.

Installation Notice

Tightening Torque

42 Nm

7. Remove the rear propeller shaft.

Installation Notice

8. Unscrew the five bolts and remove the transfer case.

9. Disconnect the 10-Pins Plug connector from transmission.

10. Separate the locking clip on shift lever and remove the

shift rod.

Notice

Removal and installation performed when the shift

procedure should be lever is in “D” range.

Screw the six bolts mounting the torque converter through

the service hole by using a mirror and rotating the engine.