Daewoo Korando. Service manual - part 193

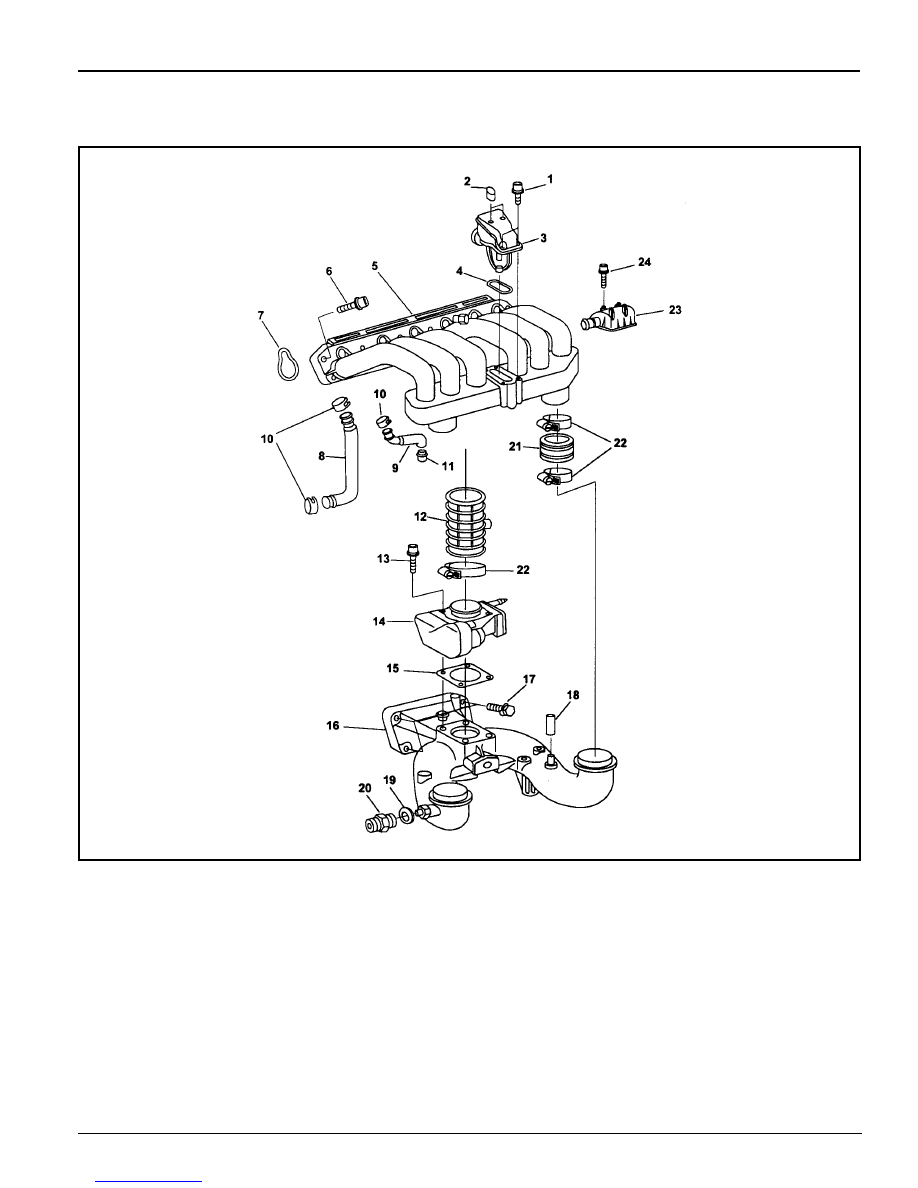

M162 ENGINE INTAKE & EXHAUST 1G1-5

INTAKE MANIFOLD

Preceding Work : Removal of fuel distributor and injection valve

1 Bolt (M6 X 40, 4 pieces) ......................... 9-11 Nm

2 Softcap

3 Resonance Flap

4 Gasket ................................................... Replace

5 Upper Intake Manifold

6 Bolt (M8 x 50, 9 pieces) ................. 22.5-27.5 Nm

7 Gasket ................................................... Replace

8 Blow-by Hose

9 Blow-by Hose

10 Clamp

11 Blow-by Nipple

12 Inlet Air Housing

13 Bolt (M6 x 40, 4 pieces) ......................... 9-11 Nm

14 Throttle Body - Electric

15 Gasket ................................................... Replace

16 Lower Intake Manifold .........................................

17 Bolt (M8 x 40, 4 pieces) ................. 22.5-27.5 Nm

18 Nipple .................................................... Replace

19 Seal Ring

20 Connection House

21 Clamp

22 Noise Damper Assembly

23 Tapping Screw