Daewoo Nubira. Service manual - part 254

2E – 8

I

TIRES AND WHEELS

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

TIRE AND WHEEL BALANCING

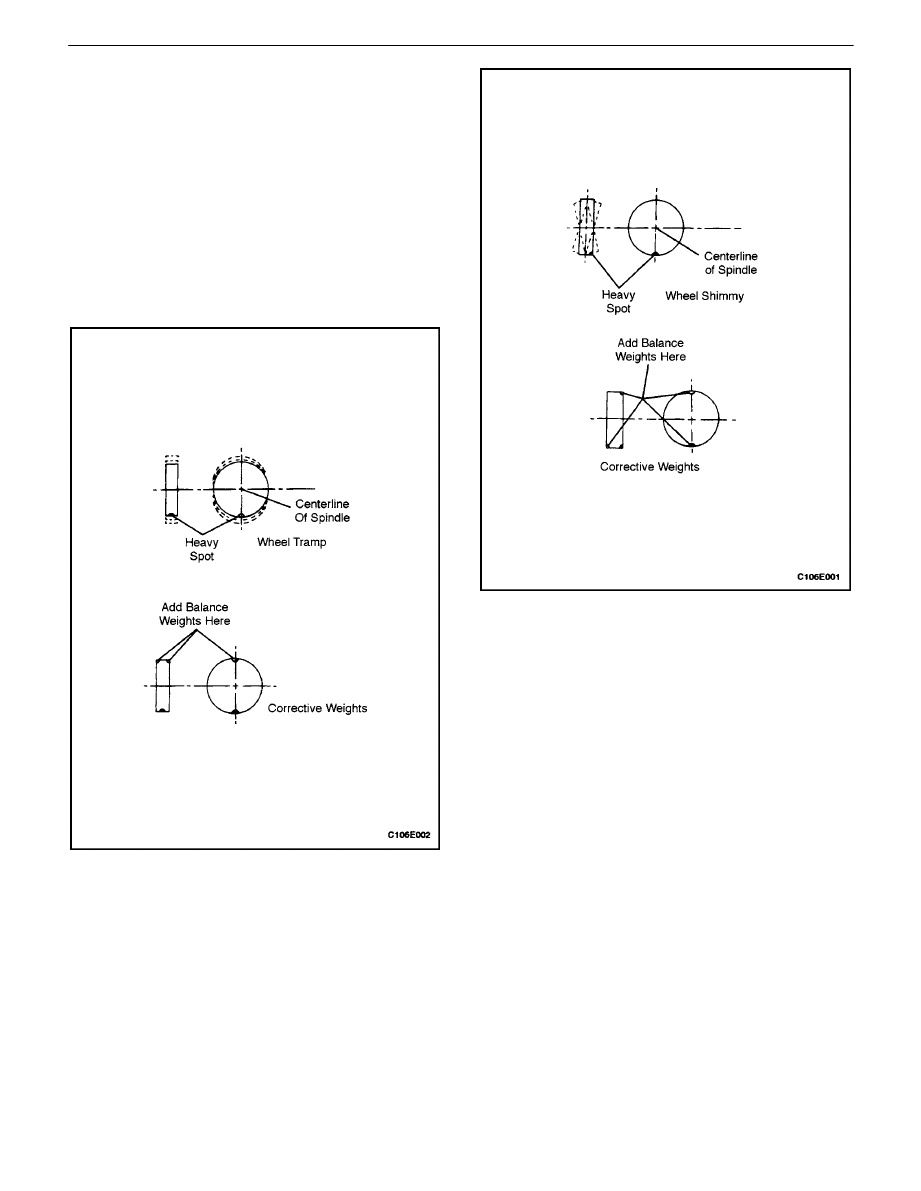

There are two types of tire and wheel balancing: static and

dynamic.

Static balance is the equal distribution of weight around

the wheel. Assemblies that are statically unbalanced

cause a bouncing action called wheel tramp. This condi-

tion may eventually cause uneven tire wear.

Dynamic balance is the equal distribution of weight on

each side of the centerline so that when the assembly

spins there is no tendency for it to move from side to side.

Assemblies that are dynamically unbalanced may cause

wheel shimmy.

General Balance Precautions

Remove all deposits of foreign material from the inside of

the wheel.

CAUTION : Remove stones from the tread in order to

avoid operator injury during spin balancing.

Inspect the tire for any damage. Balance the tire according

to the equipment manufacturer

’

s recommendations.

WheelWeights

If more than 85 grams (3.0 ounces) are needed to static

balance the wheel, split the wheel weights as equally as

possible between the inboard and the outboard flanges.

Balancing the assemblies with factory alloy wheels re-

quires the use of special nylon–coated, clip–on wheel

weights. These weights are designed to fit over the thicker

rim flange of the alloy wheel. Install these weights with a

plastic–tipped hammer.

Adhesive wheel weights are also available. Use the follow-

ing procedure to install adhesive wheel weights.