Daewoo Nubira. Service manual - part 115

1F – 42

I

ENGINE CONTROLS

DAEWOO V–121 BL4

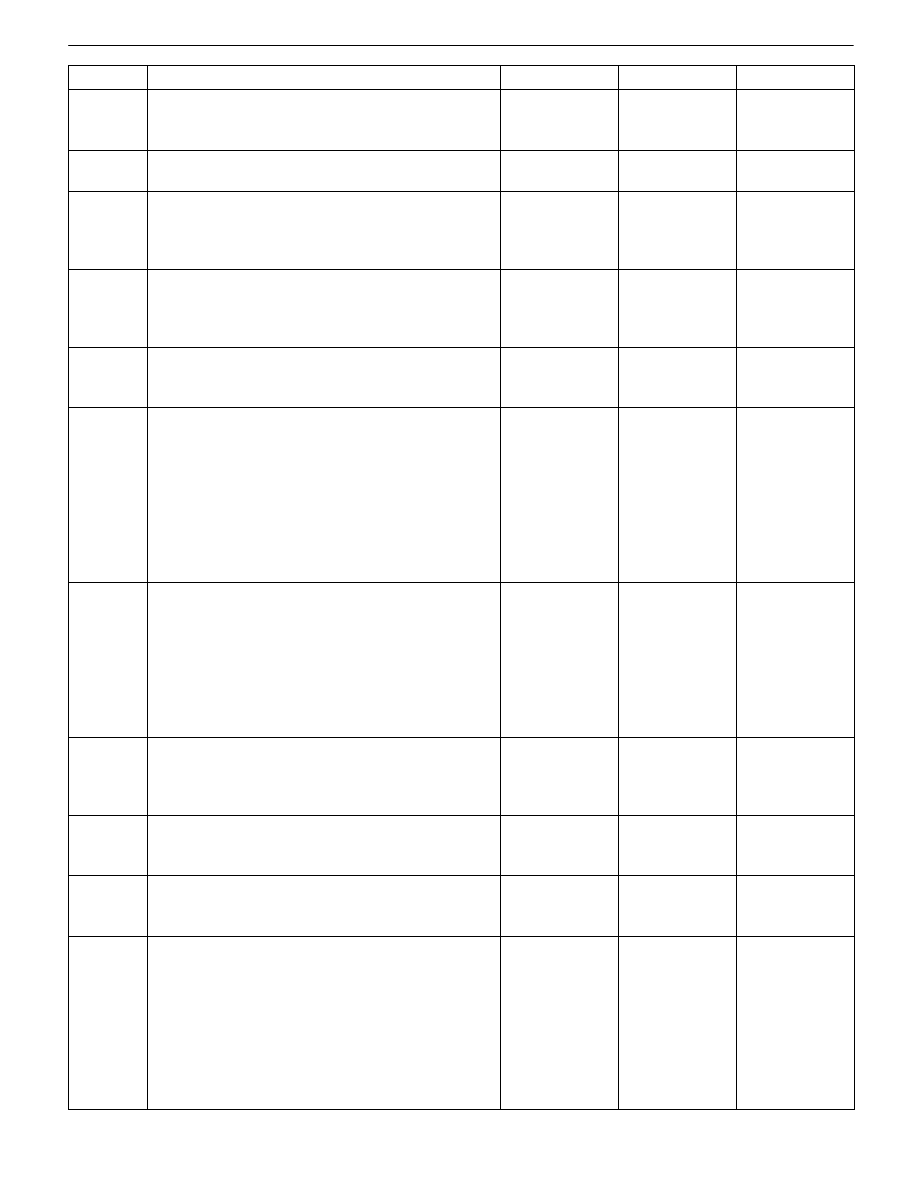

Step

No

Yes

Value(s)

Action

58

Repair the short or opening the circuit between the

fuel cutoff switch and the fuel pump.

Is the repair complete?

Go toStep 2

59

Replace the fuel cutoff switch.

Is the repair complete?

Go toStep 2

60

Check the wire between the fuel pump relay connec-

tor terminal 85 to the PCM/ECM connector terminal

E13 for an open.

Is the problem found?

Go toStep 61

Go toStep 33

61

Repair the wire between the fuel pump relay connec-

tor terminal 85 to the PCM/ECM connector terminal

E13.

Is the repair complete?

Go toStep 2

62

Repair the wire between the fuel pump relay connec-

tor terminal 30 and the battery.

Is the repair complete?

Go toStep 2

63

1. Turn the ignition OFF.

2. Disconnect the fuel injector harness connectors

from all of the fuel injectors.

3. Turn the ignition ON.

4. Connect a test light between the fuel injector

harness connector 1 and ground.

5. Repeat Step 4 for each of the remaining fuel

injectors.

Is the test light on at all of the fuel injectors?

Go toStep 64

Go toStep 67

64

1. Turn the ignition OFF.

2. Connect a test light between the fuel injector

harness connector terminal 2 and battery posi-

tive.

3. Crank the engine.

4. Repeat Steps 3 and 4 for each of the remain-

ing fuel injectors.

Does the test light flash for all of the fuel injectors?

Go toStep 65

Go toStep 68

65

Measure the resistance of each fuel injector.

Is the resistance within the value specified (the re-

sistance will increase slightly at higher tempera-

tures)?

11.6–12.4

W

System OK

Go toStep 66

66

Replace any of the fuel injectors with a resistance

out of specification.

Is the repair complete?

Go toStep 2

67

Repair the open wire(s) between the fuel injector

harness connector(s) terminal 1 and the battery.

Is the repair complete?

Go toStep 2

68

1. Check for an open between the fuel injector

harness connector terminal 2 and the PCM/

ECM connector terminal C4 for the fuel injec-

tors one and four.

2. Check for an open between the fuel injector

harness connector terminal 2 and the PCM/

ECM connector terminal C6 for the fuel injec-

tors two and three.

Is the problem found?

Go toStep 69

Go toStep 71