Chery Tiggo 5 (T21). Service manual - part 387

35–

23

35

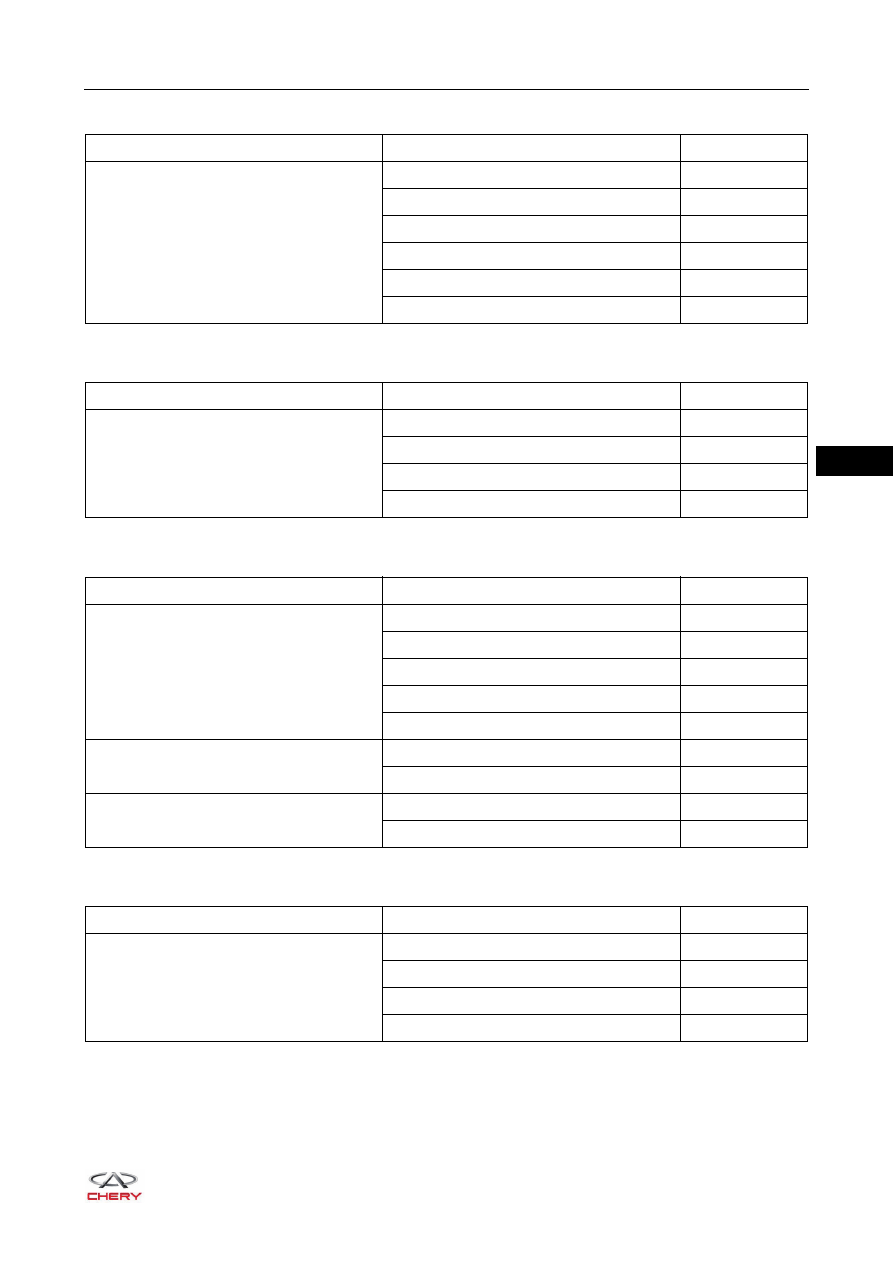

Front Fog Light

Rear Fog Light

Turn Signal Light and Hazard Warning Light

License Plate Light

Symptom

Suspected Area

See page

Front fog light does not come on

Fuse

Relay

Front fog light bulb

-

Headlight adjustment switch assembly

Wire harness or connector

-

Body Control Module (BCM)

-

Symptom

Suspected Area

See page

Rear fog light does not come on

Rear fog light bulb

-

Headlight adjustment switch assembly

Wire harness or connector

-

Body Control Module (BCM)

-

Symptom

Suspected Area

See page

Hazard warning light and turn signal light

do not come on

Bulb

-

Wire harness or connector

-

Hazard Warning Light Switch

Headlight adjustment switch assembly

Body Control Module (BCM)

-

Hazard warning light does not come on

(turn signal light is normal)

Hazard Warning Light Switch

Wire harness or connector

-

Turn signal light does not come on (hazard

warning light is normal)

Headlight adjustment switch assembly

Wire harness or connector

-

Symptom

Suspected Area

See page

License plate light does not come on

License plate light bulb

-

Headlight adjustment switch assembly

Wire harness or connector

-

Body Control Module (BCM)

-