Chery Tiggo 5 (T21). Service manual - part 216

18–

53

18

DTC Confirmation Procedure:

Confirm that battery voltage is between 11 and 14 V before performing the following procedures.

Turn ignition switch to LOCK.

Connect X-431 3G diagnostic tester (the latest software) to Data Link Connector (DLC), and make it

communicate with vehicle electronic module by the data network.

Turn ignition switch to ON.

Using X-431 3G diagnostic tester to record and clear the DTCs stored in the TCU.

Turn ignition switch to LOCK and wait for a few seconds.

Turn ignition switch to ON, and then select "Read Code".

If DTC is detected, the malfunction indicated by the DTC is current. Go to the diagnosis procedure - Step 1.

If DTC is not detected, the malfunction indicated by the DTC is intermittent. Please refer to Intermittent

DTC Troubleshooting.

Diagnosis Procedure

HINT:

After the fault is eliminated, verify DTC and symptom again.

a. Turn ignition switch to LOCK.

b. Disconnect the secondary speed sensor connector.

c. Check if the secondary speed sensor connector is dirty, oxidized, loose or damaged.

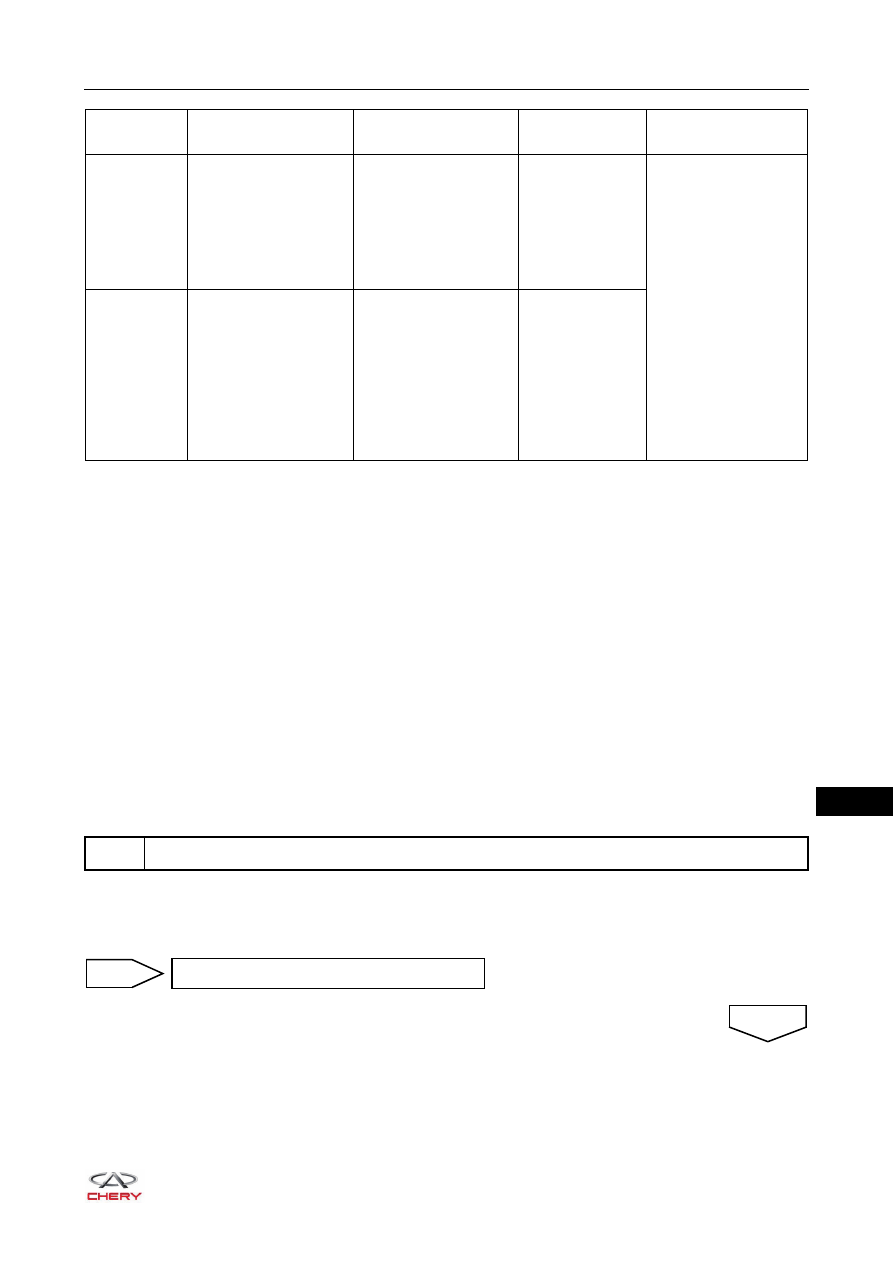

DTC Code

DTC Definition

DTC Detection

Condition

DTC Set

Condition

Possible Cause

P0720

Output Speed Sensor

Circuit

Start engine and keep

it at following status for

at least 1 min: throttle

opening not less than

10%, at D gear, engine

speed higher than 800

rpm

Output speed

signal is higher

than the

allowable value

within a period

Incorrect

installation of the

output speed

sensor

Signal circuit open

or short circuit

Output speed

sensor power

circuit poor contact

Output speed

sensor failure

TCU signal circuit

failure

P1745

Second Speed Sensor

Plausible

Start engine and keep

it at following status for

at least 30 seconds:

throttle opening higher

than 10%, at D gear,

vehicle speed higher

than 10 km/h

Difference

between output

speed after

conversing

vehicle speed

signal and actual

measured speed

is higher than

limit

1

Check wire harness connector

Repair fault

NG

OK