Chery Tiggo 5 (T21). Service manual - part 170

15–

15

15

Starter Relay Inspection

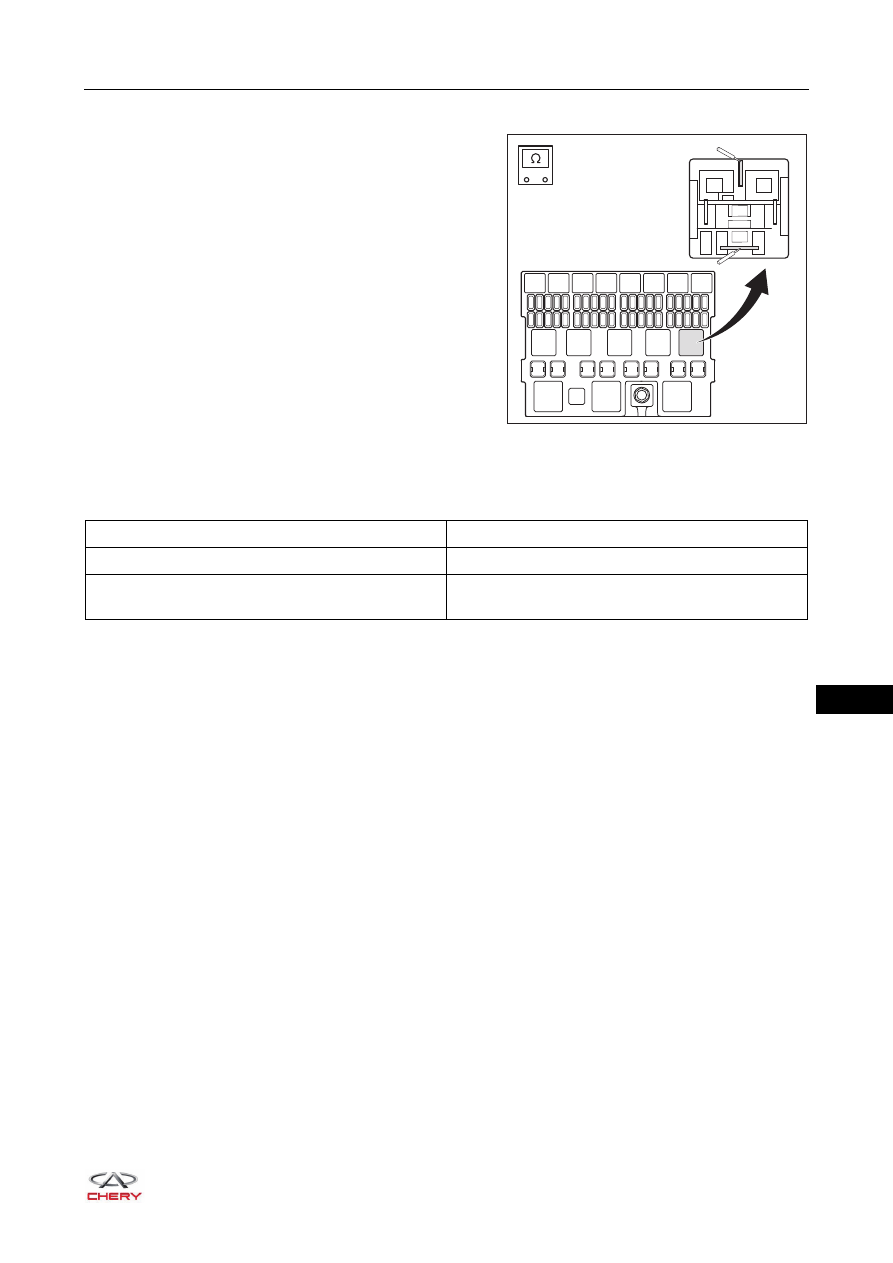

1. Remove the starter relay from engine compartment fuse

and relay box.

2. Check starter relay.

a. Using a digital multimeter, measure resistance according to the value(s) in the table below.

Standard Resistance

If result is not as specified, replace the starter relay.

RT21150040

-

+

30

85

86

87

Start relay

ERL Y09

Multimeter Connection

Specified Condition

30 - 87

10 kΩ or more

30 - 87

Below 1 Ω (when battery voltage is applied to

terminals 85 and 86)