Chery Tiggo 5 (T21). Service manual - part 113

07–

38

07

Installation

1. Install the camshaft oil seal.

HINT:

Use the same installation procedures for the exhaust camshaft oil seal and intake camshaft oil seal.

Procedures listed below are for intake camshaft oil seal.

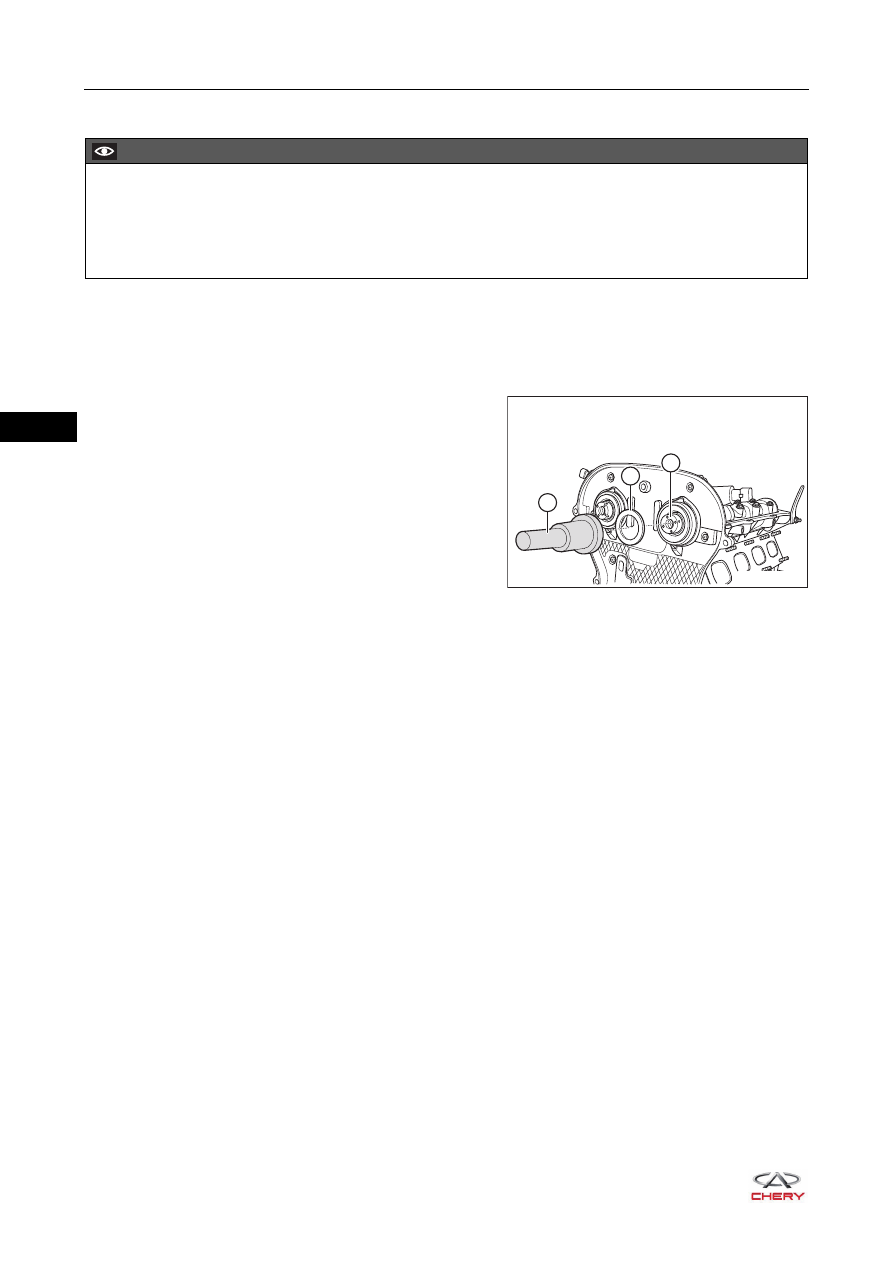

a. Using a special tool (camshaft oil seal installer) (1),

install the intake camshaft oil seal (2) to intake

camshaft (3).

2. Other installation procedures are in the reverse order of removal.

CAUTION

Remove the dirt on oil seal retainer and apply a coat of engine oil to the oil seal retainer and oil seal lip

before installation.

Be sure to prevent the lip of camshaft oil seal from being scratched during installation. If it is damaged,

replace immediately.

RT21070240

1

2

3