LG956 Wheel Loader. Service manual - part 26

Operation & Maintenance Manual──LG956L Wheel Loader

103

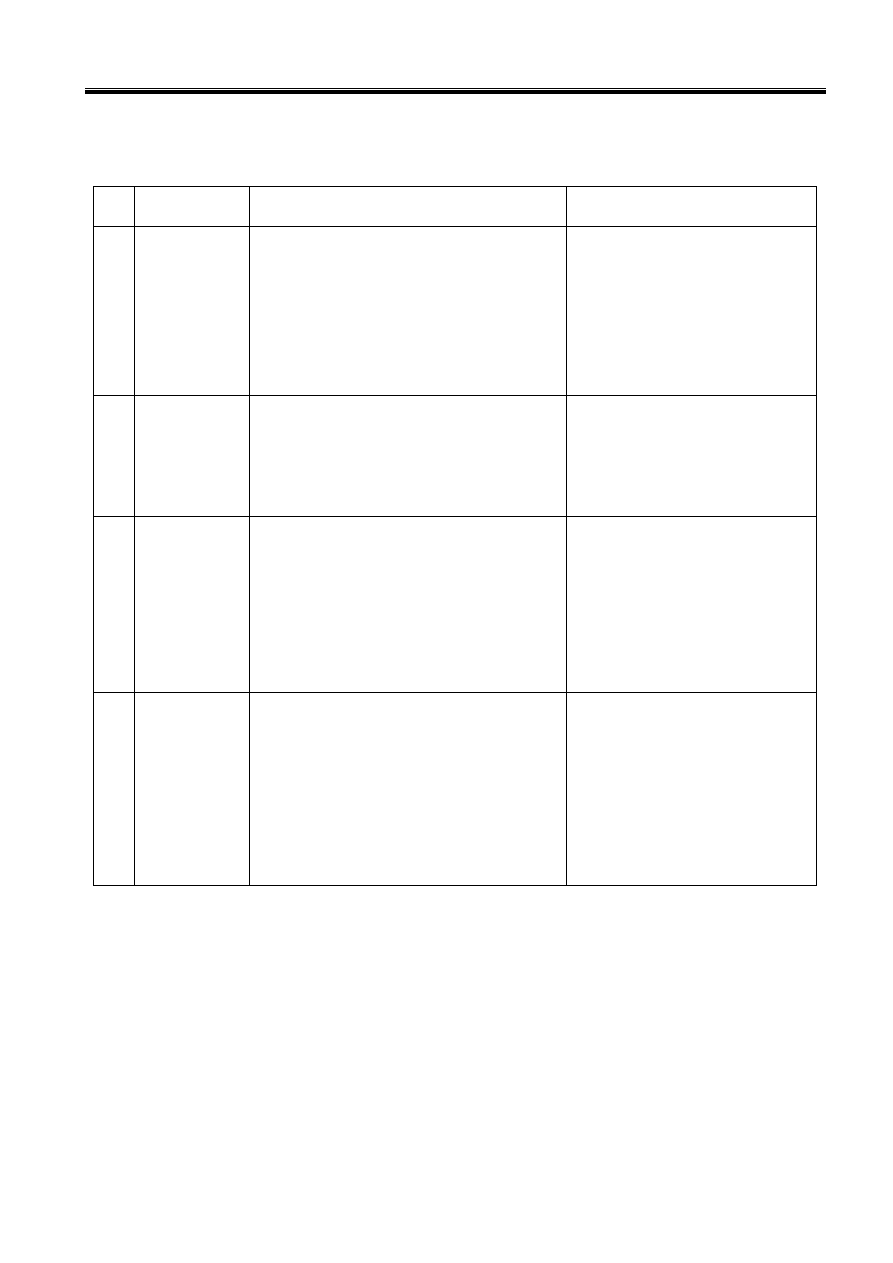

3.8.5 Steering System

No. Problems

Possible

Causes

Remedy

1

Heavy steering

1 Insufficient oil supply for working pump

and steering pump

2 Air in steering system

3 Faulty steel-ball in check valve body of

steering unit causes heavy steering and

little pressure during either slow or quick

turning of steering wheel

4 Faulty of piloted valve

5 Too low pressure of safety valve

1 Check oil pump

2 Discharge air from system and

check the suction lines

3 Check the valve. Clean if it is

blocked by dirt

4 Replace piloted valve

5 Readjust the pressure to

specified value

2

Increased

steering turns

1 Insufficient oil level in hydraulic reservoir

2 Leakage in oil lines, damaged oil seals

3 Internal leakage of steering cylinder

4 Worn steering unit

5 High viscosity of oil or wrong brand of oil

1 Fill oil to specified level

2 Change seals of oil circuits

3 Change seals of hydraulic tanks

4 Replace steering unit

5 Change by the specified oil

3

Inflexible or

failure of

steering system

1 Damaged spring plate of steering unit

2 Cracked, broken or deformed centre pin

and drive shaft

3 Faulty dual overload valve

4 Scuffed rotor and stator, scuffed valve

spool, valve body and sleeve

5 Faulty in steering pump or piloted valve

1 Change the damaged spring

plate

2 Change the center pin or drive

shaft

3 Check and repair the

bi-directional overload valve

4 Disassemble, check, clean and

assemble strictly or change parts

5 Change the damaged parts

4

Steering wheel

can not reset

1 No concentric steering column and valve

spool

2 Steering shaft axially locks the valve plug

3 Large axial resistance of steering column

4 Broken spring plate

Phenomena: medium pressure drop

increases or the relief of steering unit fails

when steering wheel stops (wheel loader

deflects from straight traveling line)

Remove the problems according to

the respective reasons.

3.8.6 Engine

Refer to

Operation and Maintenance Manual

of diesel engine for troubleshooting.