LG956 Wheel Loader. Service manual - part 22

Operation & Maintenance Manual──LG956L Wheel Loader

87

z After dumping, use the bucket to level equipment (if assembled). Rear tilt bucket to level position,

and operate the working equipment control handle to allow the lift arm to lower to prepare for

next operation.

(5) Pushing Operation

Level the bucket to the ground, and push the accelerator to

move forward. If there is blockage during moving, raise the

lift arm a little and move forward continuously. When

operating the lift arm to lift or lower, operate the control

lever between lifting and lowering operation. Never use the

lever at the raising or lowering position to ensure pushing the bucket smoothly.

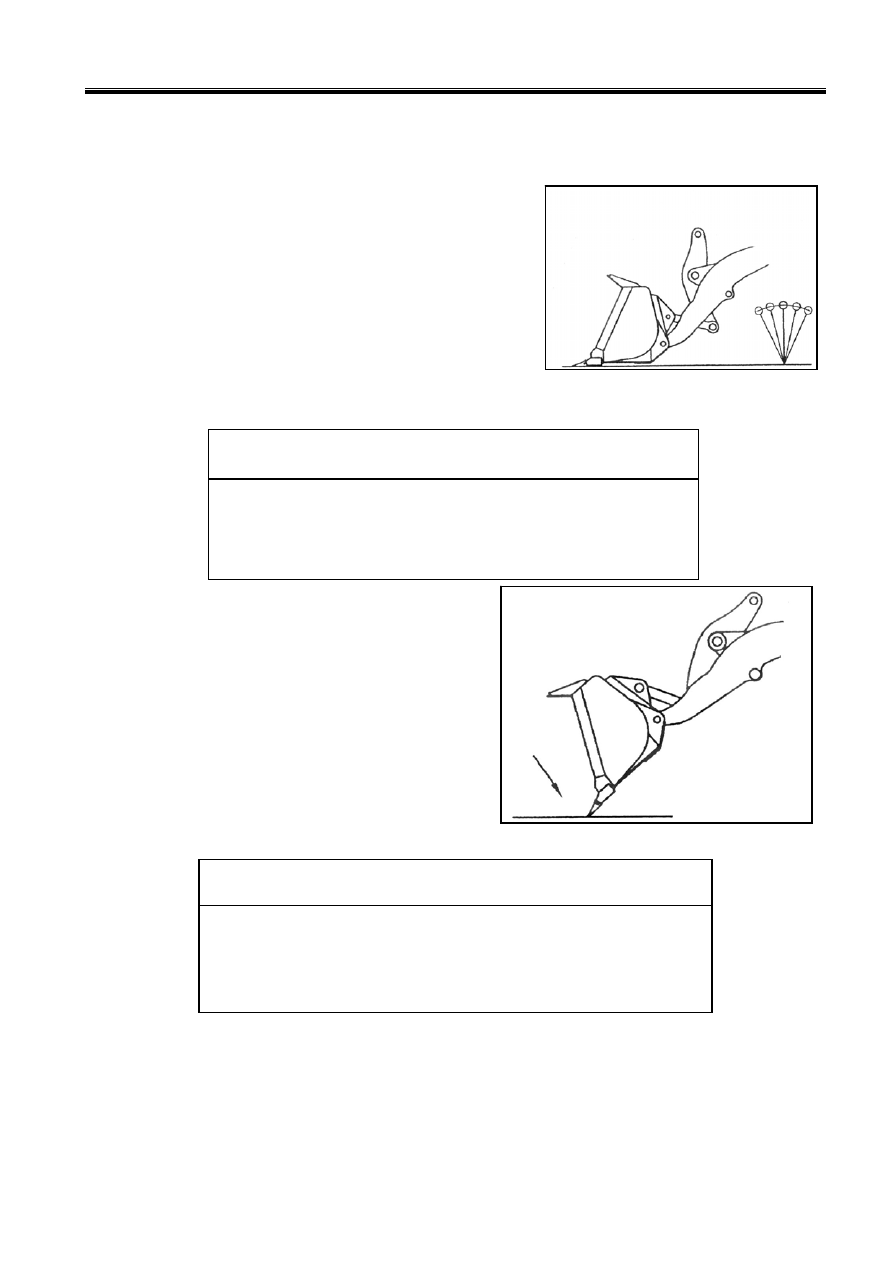

(6) Striking Operation

Tilt the bucket to let the blade touch the ground.

For hard ground, put the lift arm control lever in the

float position; for soft ground, put the lift arm control

lever in the neutral position.

Use reverse gear to strike the ground with blade.

(7) Towing Operation

△

!

WARNING

Before towing, the tires must be blocked by the parking brake to

prevent the machine from rolling.

During towing, be careful to prevent severe and fatal injury.

z If possible, the engine of the towed machine should keep the engine running to ensure braking

and turning is possible.

z If the towed machine engine can not start, disassemble the front and rear transmission axle. If the

machine can not turn, disassemble the steering cylinder.

z The connection hole of the rear frame at the inner side of the rear wheel can only be used for

△

!

NOTICE

Watch the torque converter oil temperature gauge all the time

during a pushing operation. If the temperature is too high, stop

the machine to let it cool down and then continue to work.