Lotus Evora. Instruction - part 50

Lotus Service Notes

Section JL

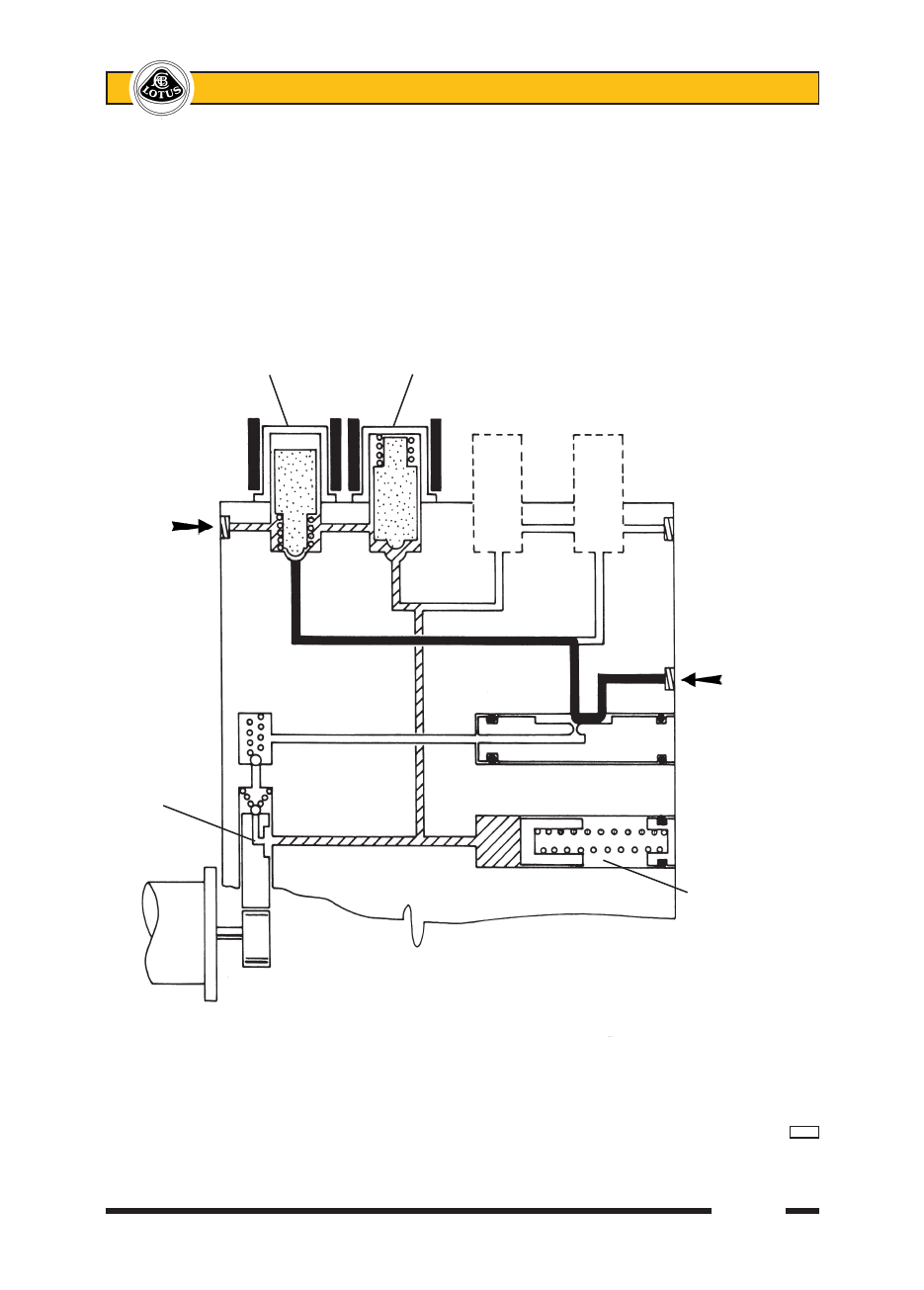

Pressure Reduction

Once the LH front wheel brake circuit has been isolated from the master cylinder, the pressure must be

reduced in order to allow wheel speed to be restored. This pressure reduction is achieved by the ECM energis-

ing the dump valve solenoid, which then opens against spring pressure and bleeds off some of the fluid into the

low pressure accumulator shared with the RH front circuit. Very short activation pulses are used to maintain

close control of the pressure reduction, and to limit the reduction to that required to restore wheel speed. Fluid

displaced from the wheel brake circuit is stored in the front brake accumulator against spring pressure, and is

also used to prime the hydraulic pump.

Isolation valve Dump valve

energised and energised and

closed open

Fluid

bleeds

off from

LHF circuit

Inlet from

master

cylinder

Pump is

primed

Low pressure

accumulator

charged

j149c