Lotus Elise / Lotus Exige. Instruction - part 114

Page 5

Lotus Service Notes

2-Eleven

2-ELEVEN.A - CHASSIS

The 2-Eleven uses the basic chassis 'tub' of the Elise/Exige with minor revisions including;

-

Deletion of door hinge upright extrusions on each end of scuttle beam.

-

Full height side members (no cabin access cut down).

-

Revised pick up points for the roll over bar.

-

Addition of a body side attachment panel to the lower edge of each chassis rail sill extension.

The front crash structure is as Elise/Exige with minor fettling revisions, and the galvanised steel rear

subframe differs only in respect of incidental fixings.

Roll-Over Bar

The tubular steel roll-over bar is substantially cross-braced, including provision for shoulder harness

anchorage, and features integral bracing struts to both front and rear. The feet of the main hoop are bolted to

tapping plates riveted into the top surface of the chassis side rails, with the front bracing struts locating against

the joint between the side rail top and scuttle cross-beam and secured by similar riveted tapping plates. The

rear bracing struts use a single fixing bolt at each side to secure to the rear subframe.

The roll-over bar complies with FIA requirements for international motorsport, but note that any additions

or modifications to the 'bar may invalidate such compliance.

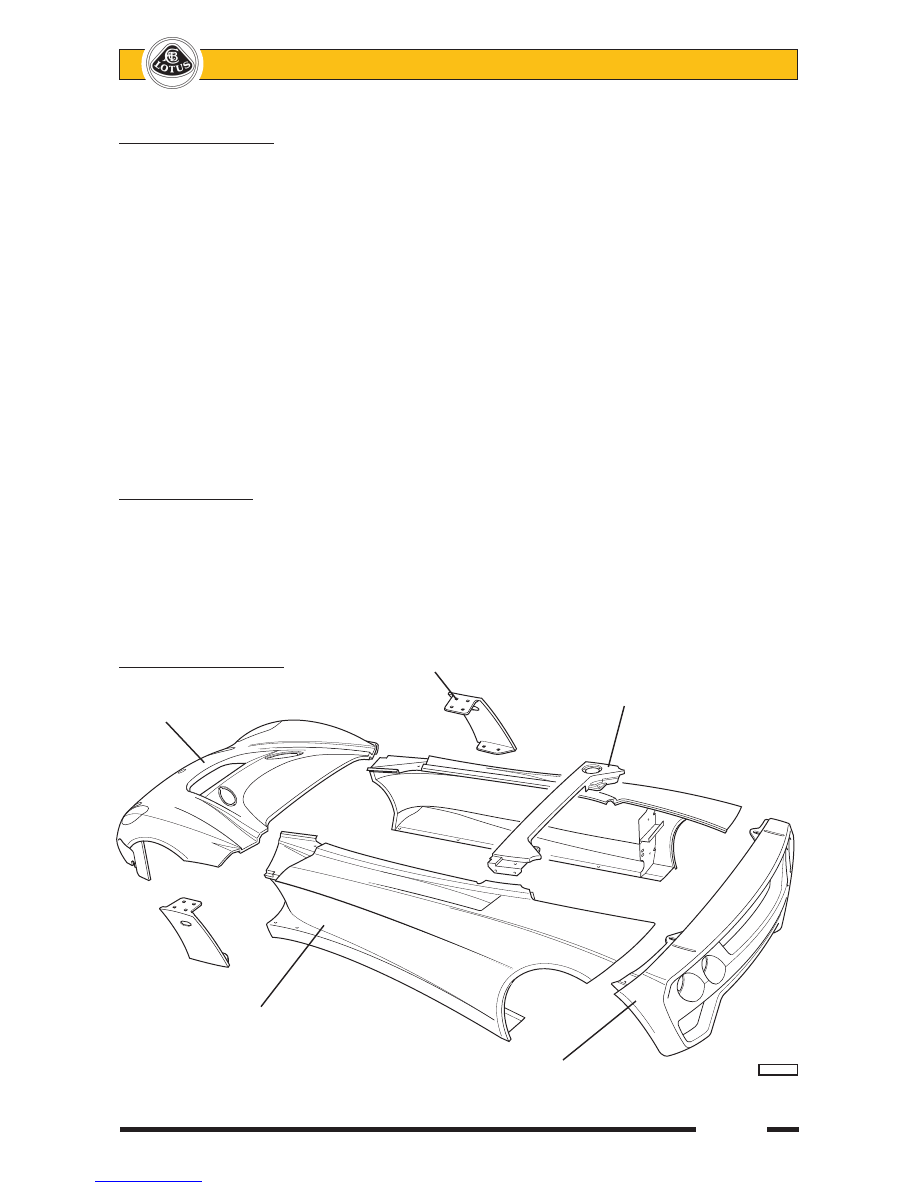

2-ELEVEN.B - BODY

On the 2-Eleven, the rear transom/bumper, body exterior side panels, ‘A’ panels, front splitter and splitter

end support panels and the single panel comprising the whole of the nose section and front wings, are secured

by threaded fasteners to permit easy removal for access to chassis or powertrain components, and allow simple

and economic accident repair. The composite body inner sides, together with the alloy sheet front and rear

cabin bulkheads and rear scuttle panel, are secured with an elastomeric adhesive.

Screw fixed body panels 'A' panel

Rear scuttle panel (also bonded)

Front body section

Body side

Rear transom/bumper

pl1001cc