Lotus Elise / Lotus Exige. Instruction - part 43

Page 46

Lotus Service Notes

Section EMP

EMP.4 - MECHANICAL THROTTLE SETTING PROCEDURE (Prior '06 M.Y.)

To avoid throttle cable strain, and ensure correct idle control and pedal operation, the following adjustments

must be maintained. If the pedal downstop is incorrectly set, overloading of the throttle body cable quadrant

can occur, resulting in quadrant distortion, closed throttle position error and engine stalling:

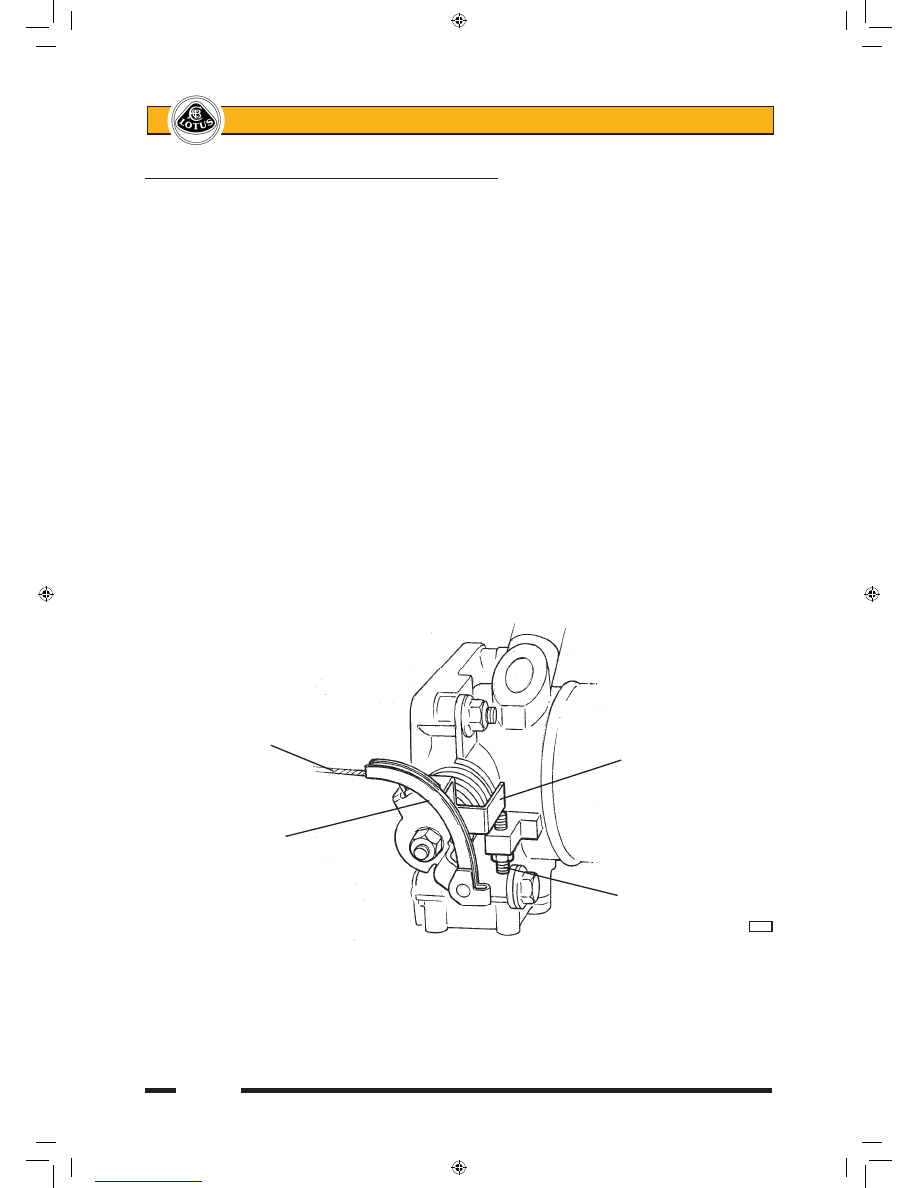

1. Check the throttle body cable quadrant for distortion and mis-alignment. If necessary, repair or replace

the quadrant.

2. Check that there is 2 - 3 mm free play at the throttle pedal, adjusting at the throttle body cable abutment

bracket if necessary.

3. If an idle control problem has been reported, reset the closed throttle stop screw on the throttle body:

With ignition off, use a hexagonal key in the bottom end of the throttle stop screw to allow the throttle but-

terfly valve to fully close, and introduce clearance between the screw and quadrant stop bracket. Screw

upwards until contact is just made, and then a further ½ turn upwards. Secure with the locknut. Recheck

cable adjustment as above.

4. Adjust the throttle pedal downstop such that vigorous full depression of the pedal achieves full opening of

the throttle butterfly without allowing the cable or mechanism to be strained.

5. If the throttle stop screw was adjusted, allow the engine to idle for 15 minutes to relearn settings.

6. An alternative pedal position which may be preferred for 'heel and toeing', may be achieved by replacing

the rubber upstop buffer with an M5x15 hex. head setscrew, with three flat washers beneath the head for

a total thickness of around 7mm. The cable must then be re-adjusted at the engine abutment as above.

The foopad downstop bolt should then be replaced by an M8x20 setscrew and reset as above.

Throttle cable

Closed throttle

stop bracket

Cable quadrant

Throttle stop screw

sb77

sn_emp_cyclone.indd 46

03/03/2006 11:03:41