Snowmobile Arctic Cat (2006 year). Instruction - part 7

24

GENERAL INFORMATION

NOTE: The measurements must

be equal and within the specifica-

tions from the chart. If the mea-

s u r e m e n t s a r e w i t h i n s p e c i -

fications, no adjustment is neces-

sary. If they are not within specifi-

cations, proceed to step 5.

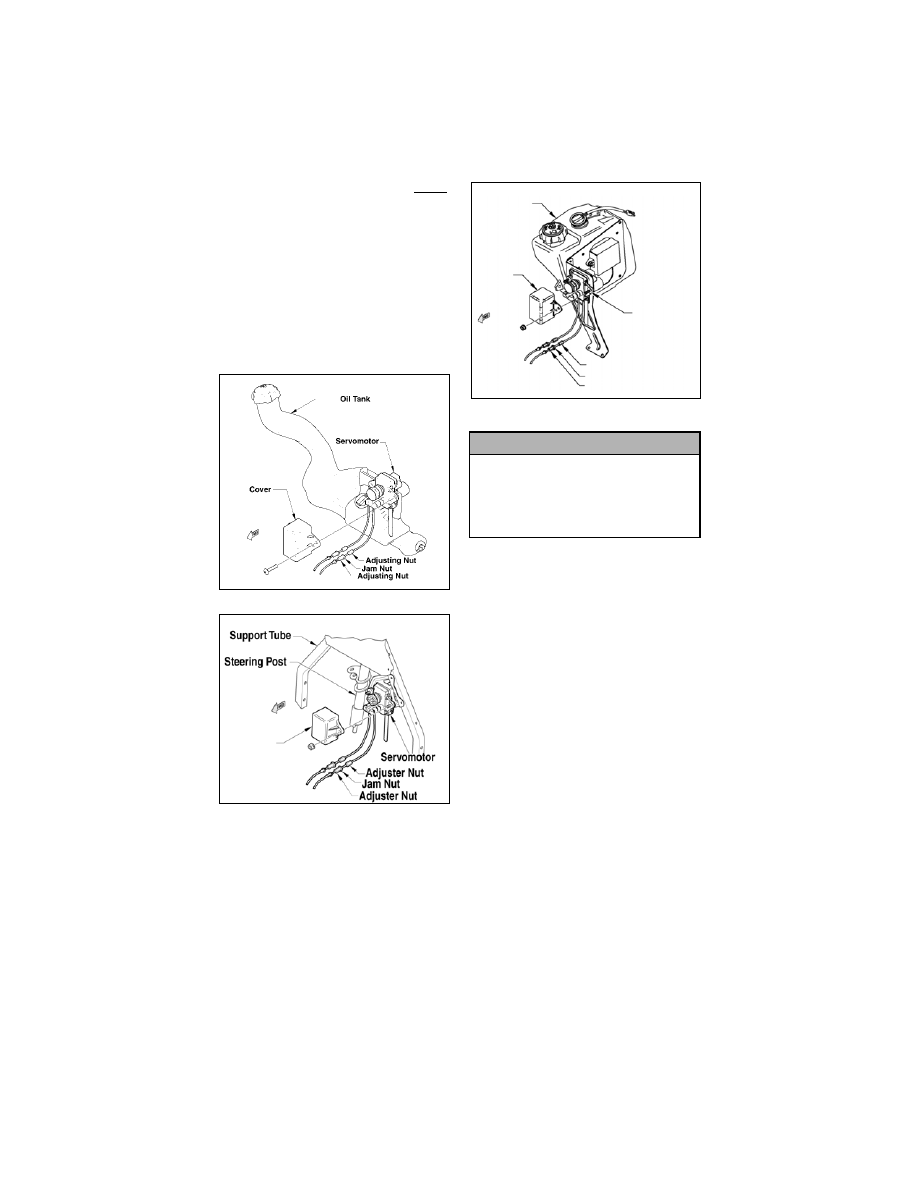

5. Loosen the jam nut on the cable

housing to be adjusted; then

u s i n g t h e a d j u s t i n g n u t s ,

lengthen or shorten the housing

as needed.

738-232B

0739-715

739-581A

6. While holding the adjusting nut

in place, tighten the jam nut

securely.

7. Install the actuating cables to

the servo; then install the servo

cover.

EXHAUST CONTROLLED

TIMING (ECT) SYSTEM (Firecat

500)

This system automatically adjusts

the ignition timing to provide maxi-

mum performance through a variety

of operating conditions. The CDI

unit receives input on engine RPM

(demand) and exhaust pipe tempera-

ture (engine condition) and adjusts

the ignition timing accordingly. This

system is not adjustable and is main-

tenance free.

Firecat/Sabercat

Crossfire/M-Series

! CAUTION

The correct engine oil to use is

Arctic Cat Synthetic APV 2-

Cycle Oil (p/n 2639-512). Any

substitute may cause an APV

malfunction.

King Cat/ZR