Snowmobile Arctic Cat (2002 year). Instruction - part 173

9-170

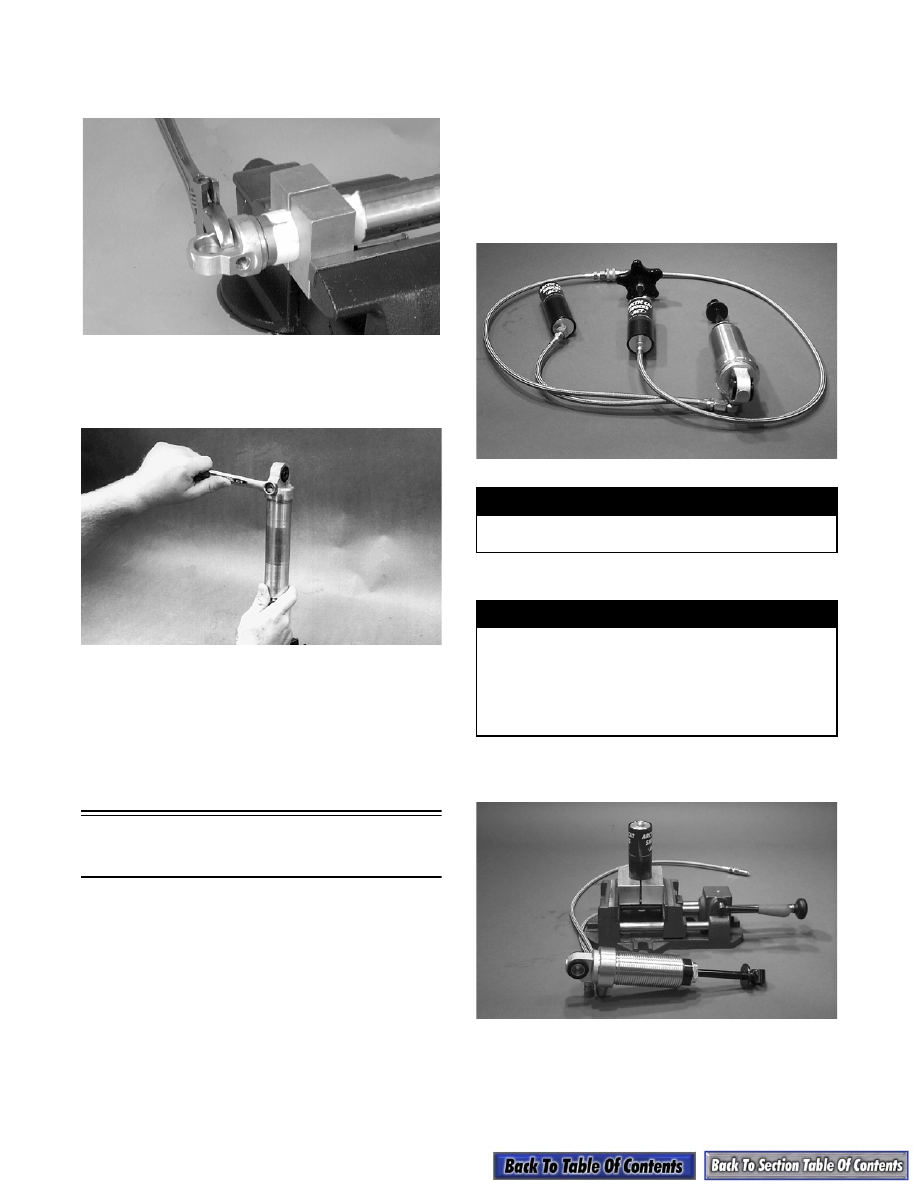

13. Using Shock Retaining Blocks (p/n 0644-142) to

hold the shock in place and using an adjustable

wrench, tighten the end cap securely.

AP016DA

14. Apply a light coat of oil on the bladder housing O-

ring; then install the brass bladder housing into the

lower end cap. Tighten securely.

AP014

15. Pressurize the shock (see Pressurizing Rebuildable

Shocks section). After shock has been pressurized,

install screw into bladder housing. Tighten

securely.

16. Install shock eyelet bushings and axle.

Servicing Front Arm

Quick-Adjust Shock

REMOVING

1. Remove the shock from the snowmobile.

NOTE: When removing the shock from the snow-

mobile, it will be necessary to disconnect the

adjuster assembly. Before disconnecting the

adjuster, the adjustment knob must be turned

completely open (counterclockwise) so there is no

pressure on the line. To prevent oil spillage, place

a protective cap on the hose end.

2. Wash the shock body in parts-cleaning solvent;

then dry with compressed air to remove sand and

dirt.

AG807

DISASSEMBLING

1. Using the Shock Retaining Blocks (p/n 0644-142),

place the remote reservoir in a vise.

AG808

2. Remove the valve screw from the pressure valve.

! WARNING

When using compressed air to dry components,

always wear safety glasses.

! WARNING

Before any work can be performed on the gas

shock absorber, first discharge all pressure from

the shock remote reservoir. Remove the valve

screw from the pressure valve and insert the Shock

Inflation Needle (p/n 0644-158). Open valve until all

pressure is released. Failure to do this may cause

personal injury.