Snowmobile Arctic Cat (2002 year). Instruction - part 122

8-46

6. Compress the brake lever repeatedly to ensure

correct positioning of the brake pads; then release.

NOTE: When new brake pads are installed, a bur-

nishing process is required. Drive the snowmobile

slowly and compress the brake lever repeatedly

until the pads just start to heat up; then allow them

to cool down. This process stabilizes the pad

material and extends the life of the pads.

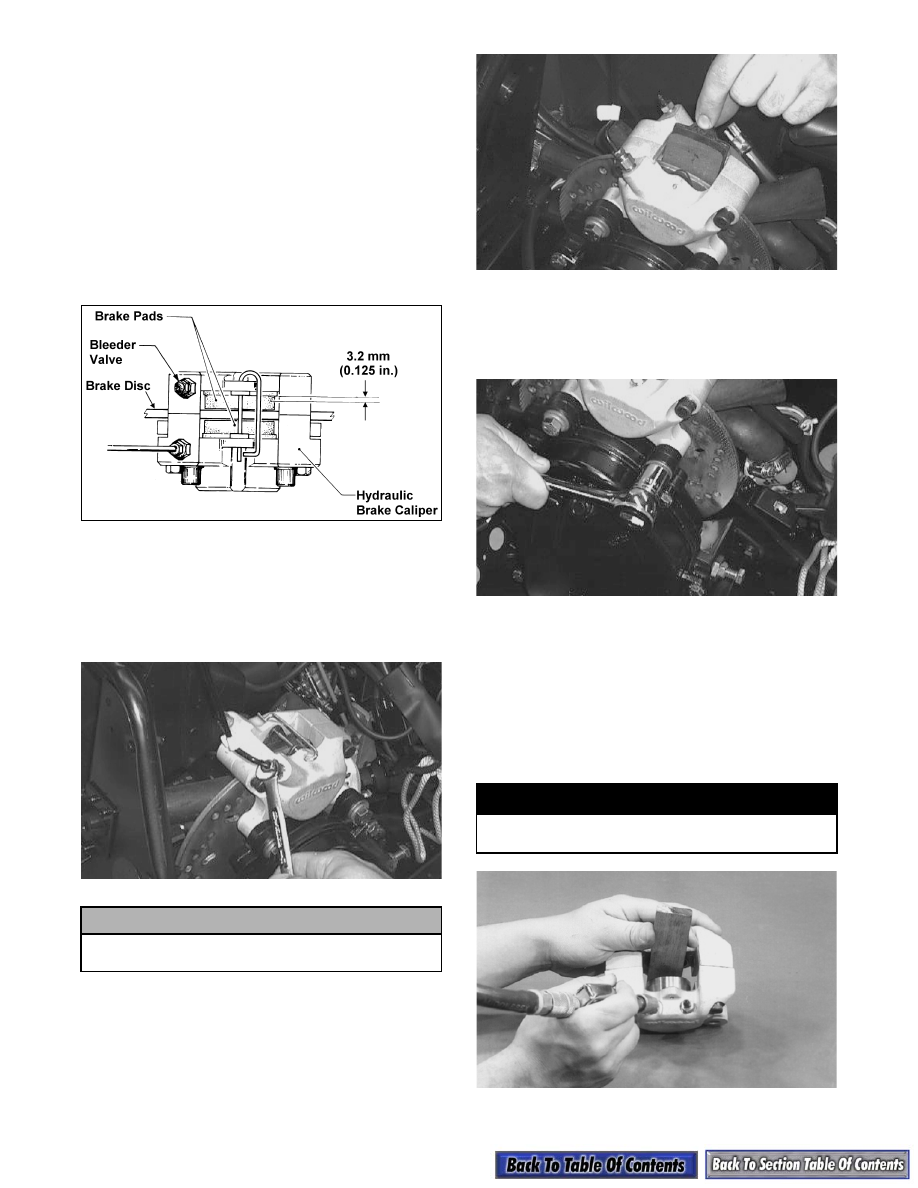

REMOVING CALIPER

1. Slide a piece of flexible tubing over the ball of the

bleeder valve and direct the other end into a

container.

0730-434

2. Open the bleeder valve and compress the brake

lever several times to drain the reservoir of fluid.

3. Remove the brake hose from the caliper. Use an

absorbent towel to collect any remaining brake

fluid.

AF262D

4. Remove the retaining pin securing the brake pads

to the caliper assembly; then remove the brake

pads.

AF255D

5. Loosen the upper cap screws securing the caliper

halves; then remove the two cap screws, lock

washers, and flat washers securing the brake

caliper to the chain case.

AF261D

6. Remove the caliper assembly from the engine

compartment.

DISASSEMBLING

1. Position a piece of wood between the pistons.

Using low-pressure compressed air, blow into the

caliper brake hose fitting to remove the brake

pistons.

AF248

! CAUTION

Brake fluid is highly corrosive. Do not spill brake

fluid on any surface of the snowmobile.

! WARNING

Always wear safety glasses when using com-

pressed air.