Snowmobile Arctic Cat (2002 year). Instruction - part 78

5-31

5

B170

4. Spark-plug cap resistance must be between 4000-

6000 ohms.

IGNITION SWITCH

1. Remove the main wiring harness connectors from

the ignition switch.

2. Rotate the key to the OFF position.

3. The meter must read less than 1 ohm of resistance

between the ignition switch terminals.

4. Rotate the key to the RUN position.

5. The meter must indicate OL (infinite resistance).

Testing Electrical

Resistances

(600 cc Triple Model)

NOTE: Resistance tests of the engine electrical

components should be made using the Fluke Mul-

timeter only. Analog-style multitesters may not be

accurate enough to use in these critical tests.

Replace any component that does not have a test

value within specifications.

IGNITION COIL (Primary)

1. Disconnect the spade connectors from the ignition

coil body.

2. Set the selector in the X1 position.

3. Connect the red meter lead to the positive spade

terminal; then connect the black meter lead to the

negative spade terminal.

AK051D

4. Ignition coil primary resistance must be between

0.29-0.39 ohm.

IGNITION COIL (Secondary)

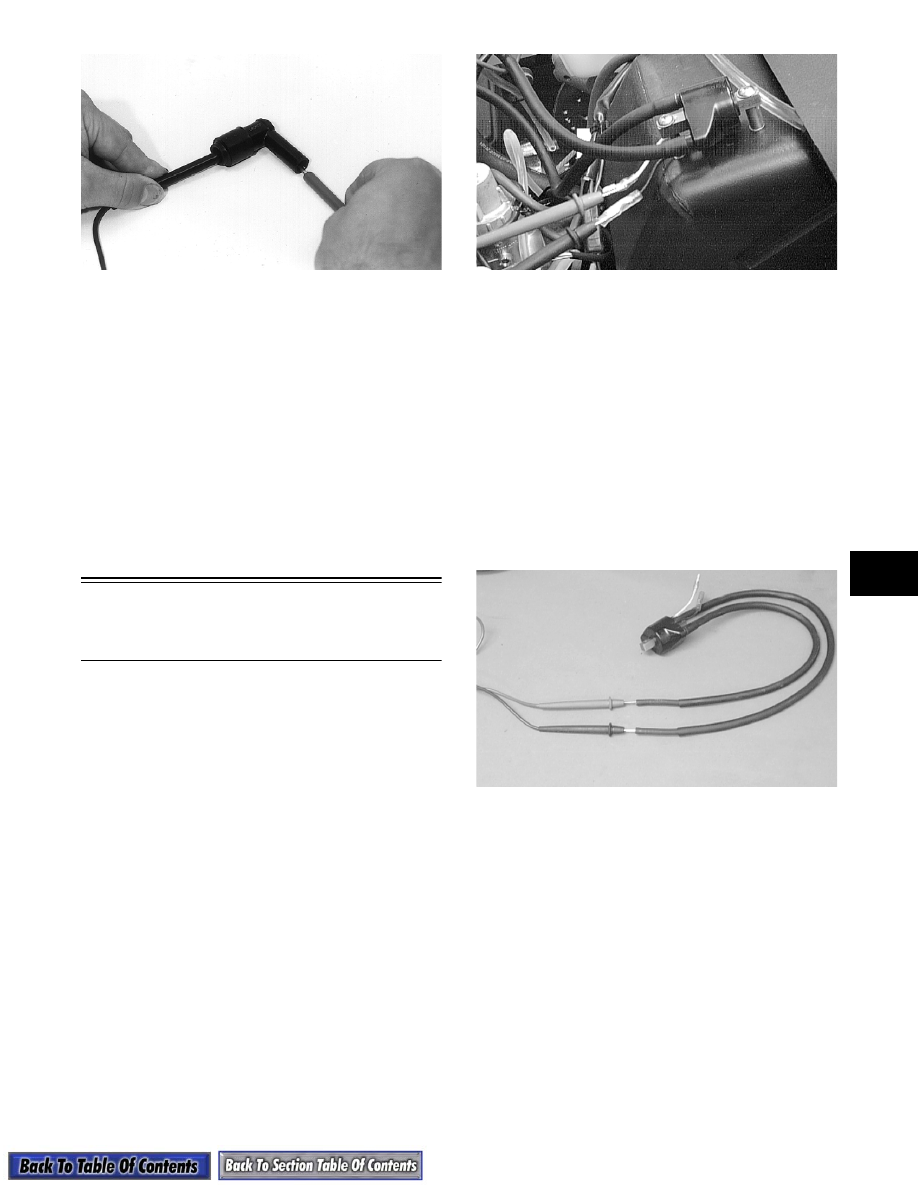

1. Remove the spark-plug caps from the high tension

wires.

2. Set the selector in the X1K position.

3. On the dual lead coil, connect the red meter lead to

one high tension wire; then connect the black

meter lead to the other high tension wire.

4. On the single lead coil, connect the red meter lead

to one high tension wire; then connect the black

meter lead to the positive spade terminal.

AK050D

5. Ignition coil secondary resistance must be between

6320-9480 ohms on both coils.

DC POWER COIL

NOTE: On APV-equipped carbureted models, the

traditional charge coil(s) have been replaced by a

single DC power coil on the stator.

1. Disconnect the two plugs (red/yellow and yellow/

red) from the CDI unit to the DC power coil.

2. Set the selector in the X1 position.

3. Connect the red meter lead to one wire; then

connect the black meter lead to the other wire.

4. DC power coil resistance must be between 0.71-

1.07 ohms.