Snowmobile Arctic Cat (2002 year). Instruction - part 38

2-135

2

AP118C

AP117

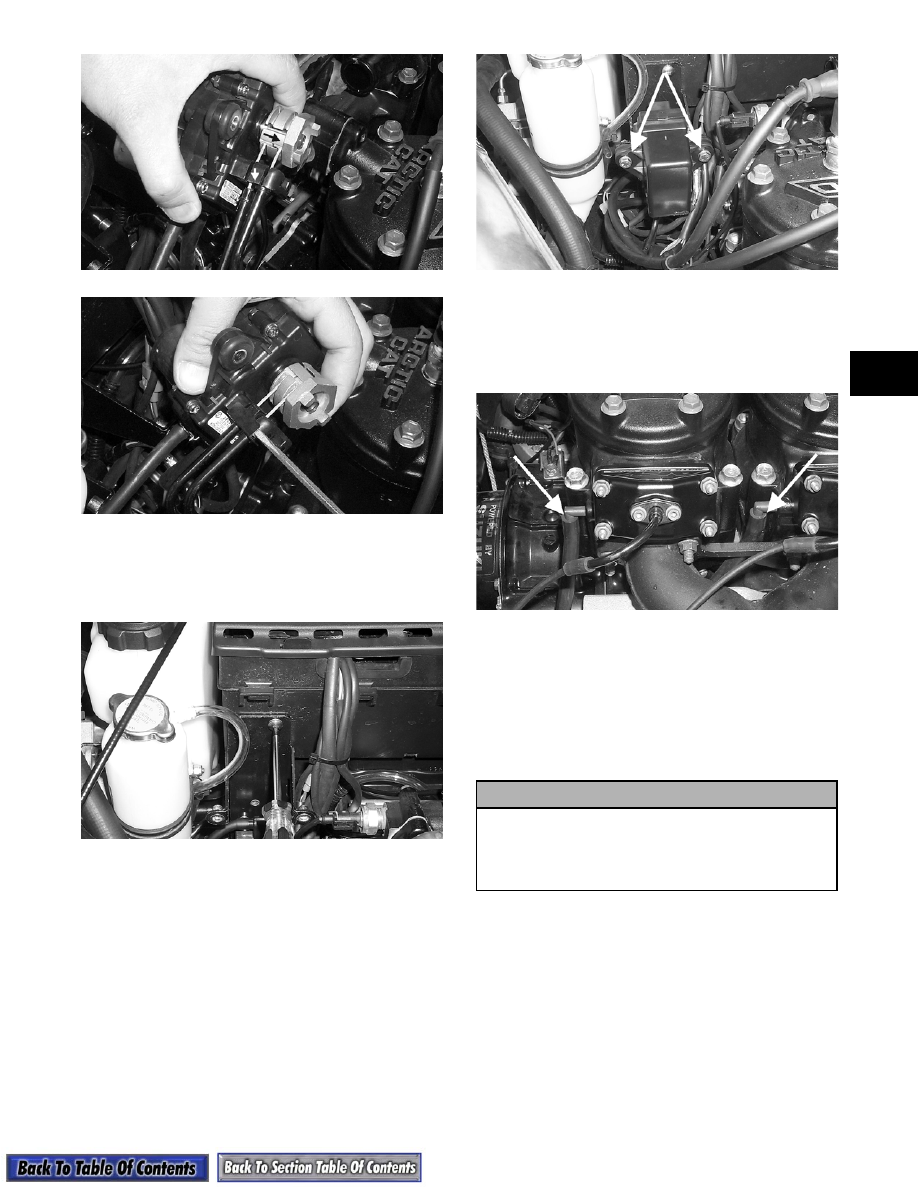

22. Position the tab (on the bottom of the servomotor

mounting plate) into the slot in the air-intake

silencer; then secure the mounting plate to the

silencer with a screw.

AP127

23. Place the servomotor with cover into position on

the mounting plate; then secure with two cap

screws.

AP116A

24. Check APV cable adjustment. See Arctic Power

Valve (APV) System in Section 3.

25. Connect the two APV drain hoses making sure

they are not in contact with hot or moving parts.

AP128A

26. Turn the gas tank shut-off valve to the OPEN

position.

27. Start engine and verify ignition timing.

28. Test drive or run the snowmobile and recheck the

coolant level after 5-6 minutes. Tighten the drive

clutch cap screw to 7.6 kg-m (55 ft-lb).

! CAUTION

If the engine had a major overhaul or if any major

component was replaced, proper engine break-in

procedures must be followed. If the proper

engine break-in procedures are not followed,

severe engine damage may result.