Snowmobile Arctic Cat (2002 year). Instruction - part 15

2-43

2

AN233

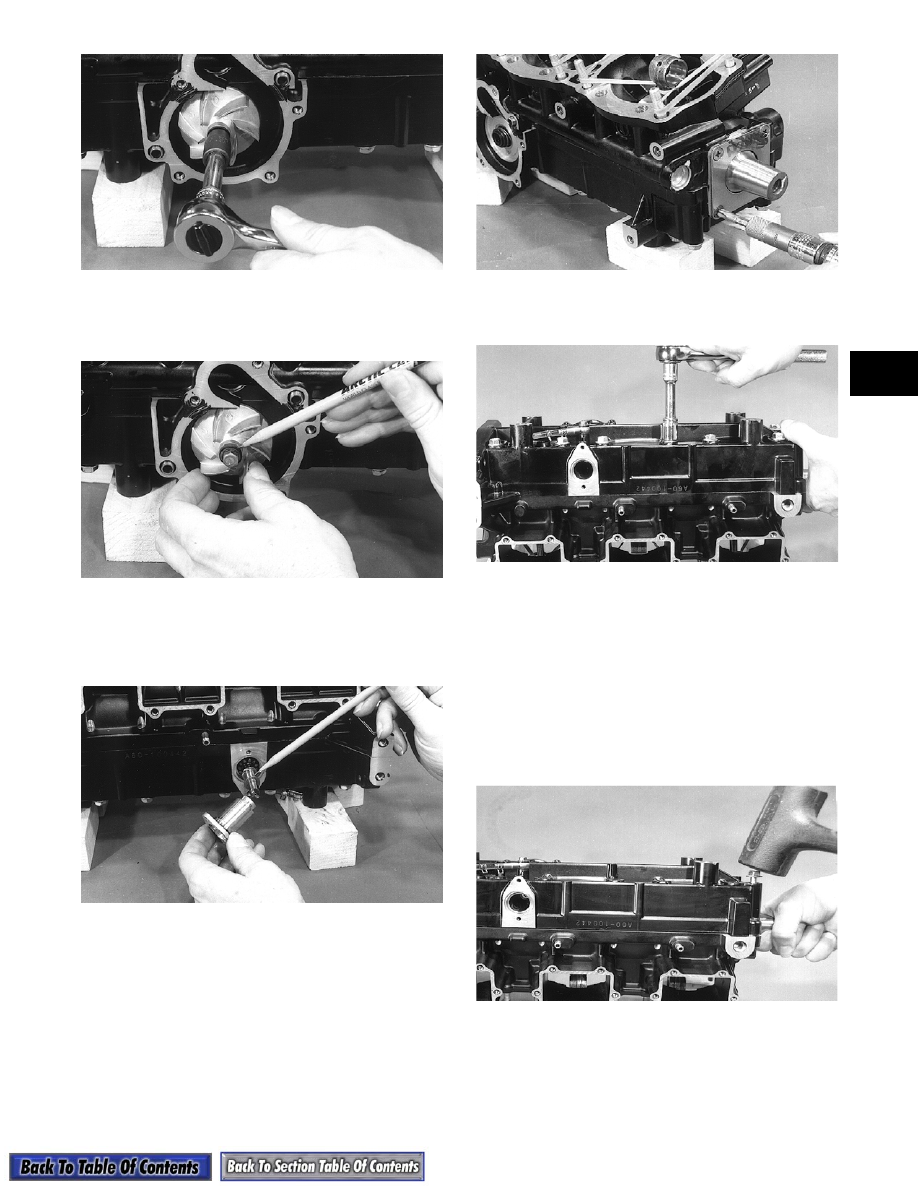

24. Using a plastic hammer, gently tap on the head of

the cap screw until the impeller is free of the shaft.

Remove the cap screw and impeller.

AN232

25. From the opposite side of the crankcase, remove

the oil pump retainer and shaft. Account for the

shaft thrust washer located between the retainer

and shaft flange.

AN231

26. Using an impact driver, remove the four screws

securing the seal protector plate to the end of the

crankcase; then slide the plate free of the

crankshaft.

AN230

27. Remove the 14 cap screws securing the two

crankcase halves together.

AN229

28. To separate the crankcase halves, start two of the

crankcase cap screws into the crankcase at

opposite corners. Thread the cap screws into the

crankcase until a 6.4 mm (1/4 in.) space remains

between the cap screw flange and the crankcase

surface.

29. Set the crankcase on its side with the flat reed

surfaces resting on the work bench. Using a

hammer, strike the heads of the two cap screws

alternately driving the two case halves apart.

AN227

30. Once there is a 6.4 mm (1/4 in.) space between the

two case halves, set the crankcase down on the

work bench with its bottom side up. Remove the

cap screws; then lift the bottom of the crankcase

free of the engine.