Snowmobile Yamaha Phazer PZ50 (2007-2008 year). Instruction - part 29

4-11

POWR

TR

Order

Job name/Part name

Q’ty

Remarks

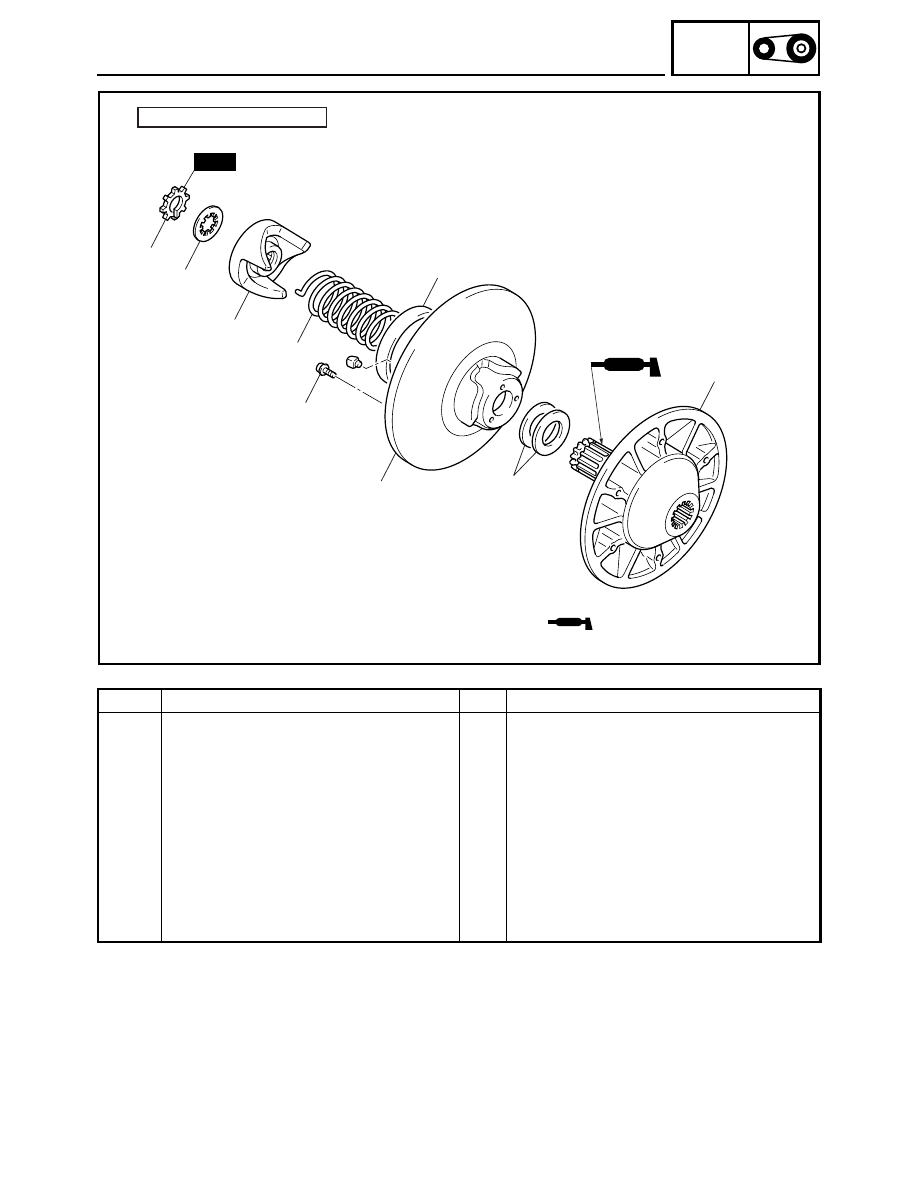

Secondary sheave disassembly

Remove the parts in the order listed below.

1 Circlip

1

2 Washer

1

3 Spring

seat

1

4 Secondary

sheave

spring

1

5 Sliding

sheave

1

6 Washer

2

7 Fixed

sheave

1

8 Bushing

1

For assembly, reverse the disassembly pro-

cedure.

1

2

3

4

8

7

5

6

7 Nm (0.7 m

•

kg, 5.1 ft

•

lb)

È:

È

: 1 ESSO beacon 325 grease

or Aeroshell grease #7A

New