Snowmobile Yamaha FX10X, FX10RTX, FX10RTRX, FX10RTRAX, FX10MTX, FX10MTRX, FX10MTRAX. Instruction - part 80

8-14

–

+

ELEC

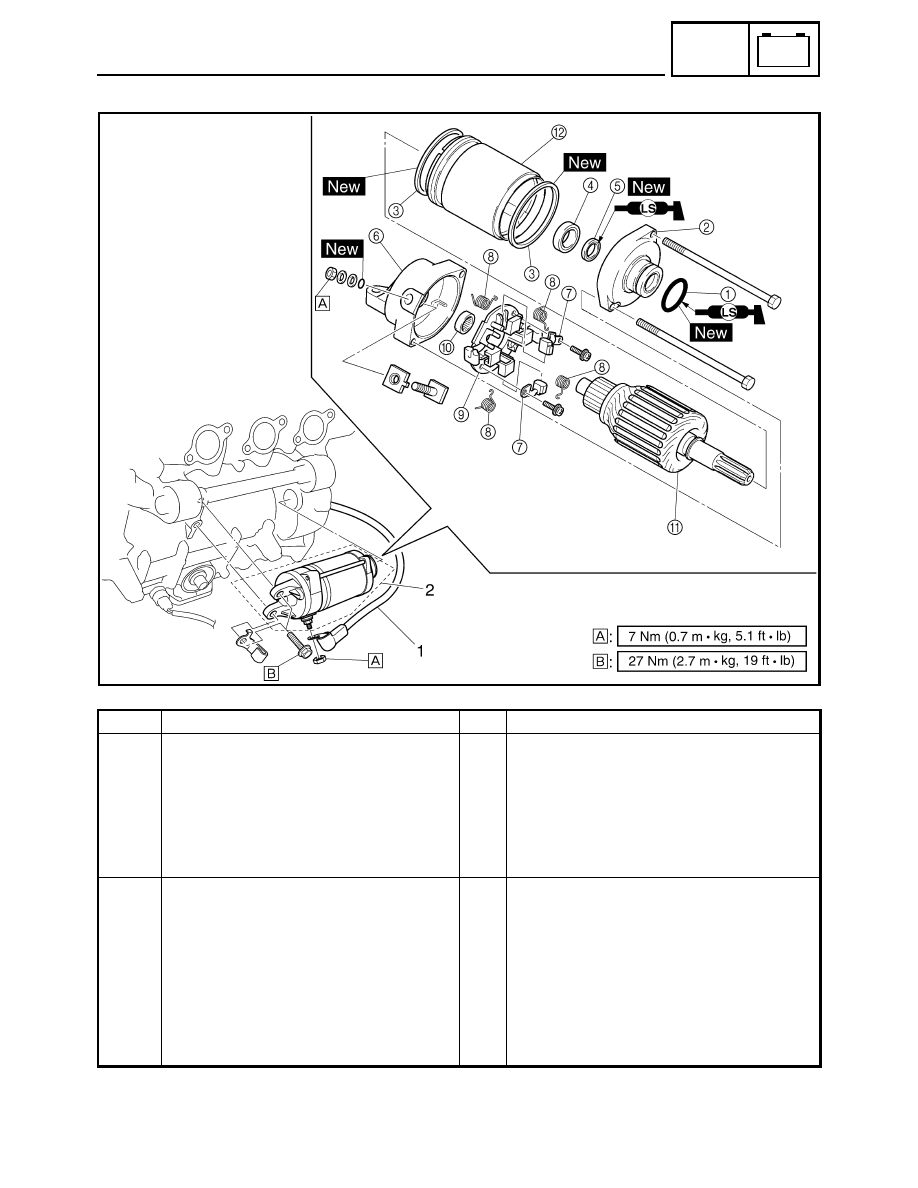

STARTER MOTOR

Order

Job name/Part name

Q’ty

Remarks

Starter motor removal

Remove the parts in the order listed below.

Engine assembly

Refer to “ENGINE ASSEMBLY” in CHAPTER

5.

1

Starter motor lead

1

2

Starter motor assembly

1

For installation, reverse the removal proce-

dure.

Starter motor disassembly

Remove the parts in the order listed below.

1 O-ring

1

2 Front

bracket

1

3 Gasket

2

4 Bearing

1

5 Oil

seal

1

6 Rear

bracket

1

7 Brush

2

8 Brush

spring

4