Snowmobile Polaris Two Stroke (2007 year). Instruction - part 62

9.31

REAR SUSPENSION

9

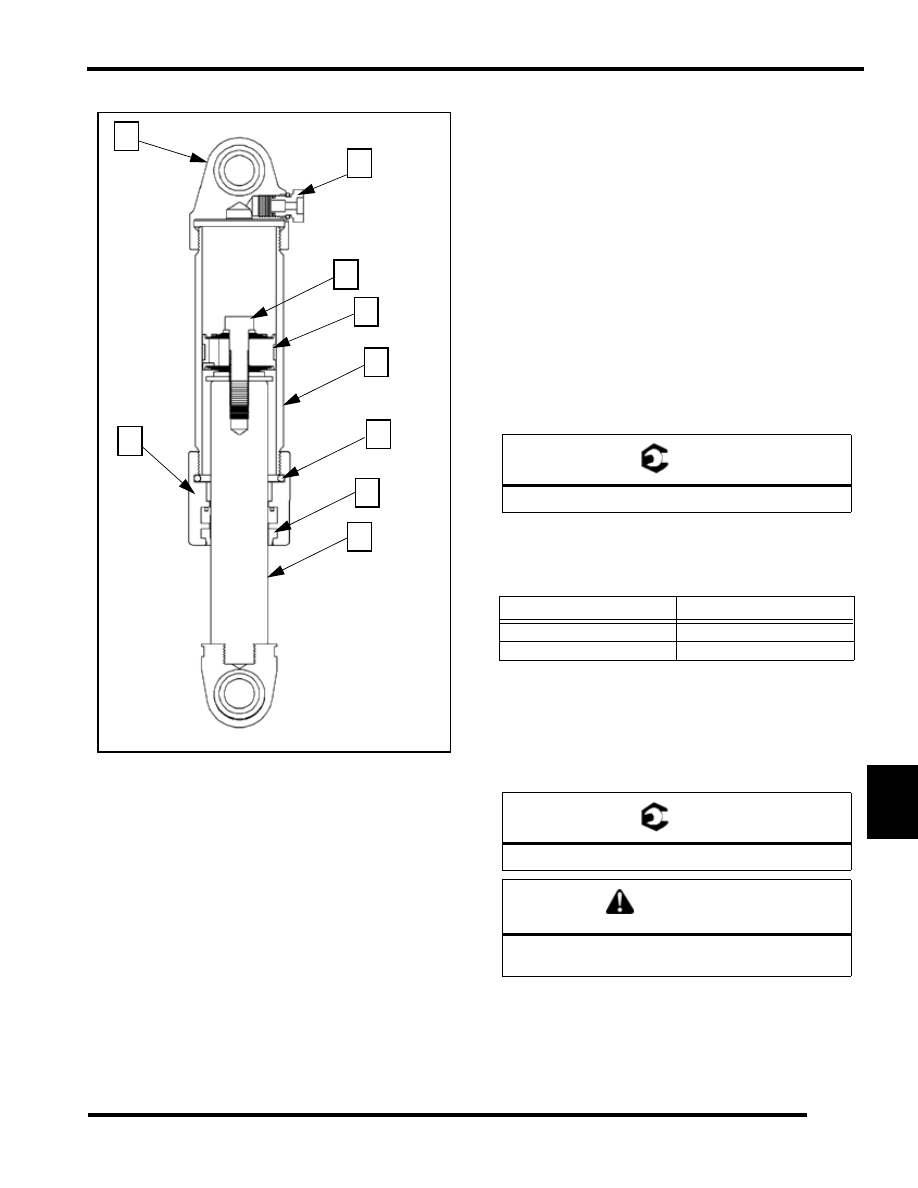

Walker Evans Shocks (7043234, 7043233)

This type of shock has some critical servicing items that you will

need to address when servicing these shocks. There are three

ways that you can adjust the performance of the shock; by

adjusting the shim stack, adjusting the fluid level and adjusting

the pressure.

Shim stacks can be adjusted just like any other shock.

Nitrogen pressure must be 215 psi (14.8 bar) for these shocks

(7043234, 7043233).

Fluid level must be at 70cc for the front track shock and 95 cc

for the IFS shock.

IMPORTANT: Some important notes when rebuilding

these shocks are listed in bullet points below.

• Protect the shock rod with supplied sleeve when

removing or installing the shock on the vehicle.

• When charging or discharging the shock always have

the shock rod facing downward.

• Fluid level and Nitrogen pressure are critical.

1.

Place the body cap (1) of the shock in the vise so that the

shock rod (2) is facing downward.

2.

Remove the service port screw (3) and release the pressure

with the shock charging needle.

3.

Make sure that all pressure is out of the shock or oil may

spray out in step 5.

4.

Place the body cap (1) in the vise, so that the shock rod (2)

is facing upward.

5.

Slowly loosen the shock rod bearing cap (4) and remove it

from the shock.

6.

Empty all the shock oil from the shock body and discard

the old oil.

7.

At this time you can service or adjust the valve stack (5) as

needed.

8.

If service or adjustment was done at this time torque the

piston retaining bolt (6) to 25-30 ft-lb (34-41 N-m).

9.

If needed remove the body cap and install a seal (7)/O-ring

(8) kit.

10. Place the specified amount of fluid into the shock body.

IMPORTANT: Be sure to only insert the required

amount of 5wt shock fluid -2cc / + 1cc. If more than the

specified amount is inserted shock damage will

occur.

11. Insert and torque down the shock rod assembly into the

shock body (9) to 85 ft-lb (115 N-m).

12. Flip shock over in the vice so that the shock rod is facing

downward.

13. Pressurize the shock to 215 psi (14.8 bar).

IMPORTANT: Fill shock with Nitrogen to 215 psi (14.8

bar). Do not fill the shock and re-check. The volume in

3

1

6

7

2

9

4

5

8

= T

Piston retaining bolt: 25-30 ft-lb (34-41 N-m)

S

HOCK

PN

F

LUID

L

EVEL

7043234 (FTS)

70cc

7043205 (RTS)

95cc

= T

Body Cap Torque: 85 ft-lb (115 N-m)

CAUTION

Do not over torque the shock rod bearing cap or

shock performance will be compromised.