Snowmobile Polaris Two Stroke (2007 year). Instruction - part 48

7.19

FINAL DRIVE/BRAKES

7

HYDRAULIC BRAKE SYSTEM

Overview

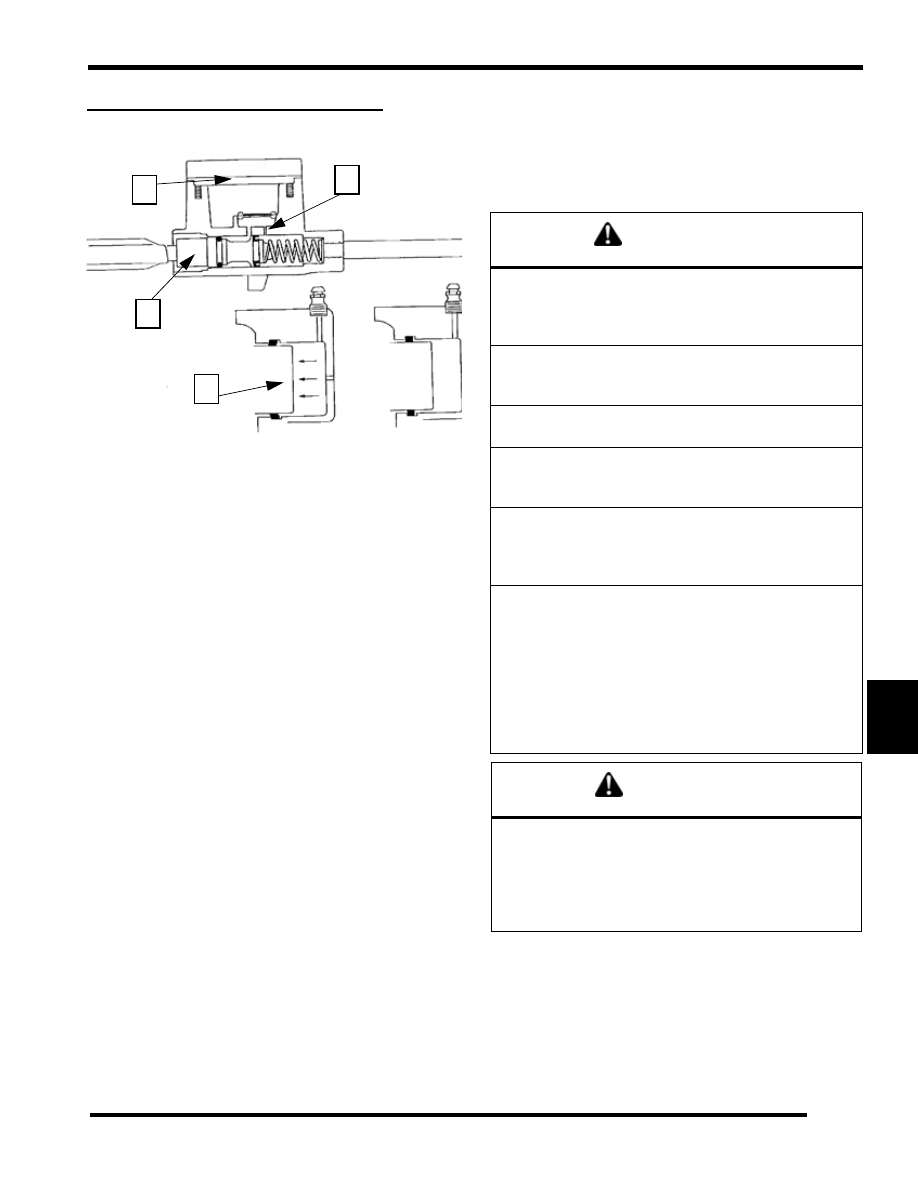

The Polaris snowmobile hydraulic brake system consists of the

following components or assemblies: brake lever, master

cylinder, hydraulic hose, brake caliper (slave cylinder), brake

pads, and a brake disc which is secured to the drive line.

When the hand activated brake lever (A) is applied, it contacts

a piston (B) within the master cylinder. As the master cylinder

piston moves inward it closes a small opening called a

compensating port (C) within the cylinder and starts to build

pressure within the brake system. As the pressure within the

system is increased, the pistons (D) located in the brake caliper

move toward the disc and applies pressure to the moveable

brake pads. As the lever pressure is increased, the braking effect

is increased.

The friction applied to the brake pads will cause the pads to

wear. As the pads wear, the piston within the caliper self-adjusts

and moves further outward.

Brake fluid level is critical to proper system operation. A low

fluid level allows air to enter the system causing the brakes to

feel spongy.

Compensating Port

Located within the master cylinder is a small compensating port

(C) which is opened and closed by the master cylinder piston

assembly. The port is open when the brake lever is released and

the piston is outward. As the temperature within the hydraulic

system changes, this port compensates for fluid expansion

caused by heat, or contraction caused by cooling. During system

service, be sure this port is open. Due to the high temperatures

created within the system during heavy braking, it is very

important that the master cylinder reservoir have adequate space

to allow for the brake fluid to expand. Master cylinder reservoirs

should be filled to the top of the fluid level mark on the inside

of the reservoir, 1/4" - 5/16" (.6 -.8 cm) below lip of reservoir

opening.

This system also incorporates a diaphragm (E) as part of the

cover gasket and a vent port (on cover) located between the

gasket and the cover. The combination diaphragm and vent

allow for the air above the fluid to equalize pressure as the fluid

expands or contracts. Be sure the vent is open and allowed to

function. If the reservoir is overfilled or the diaphragm vent is

plugged, the expanding fluid may build pressure in the brake

system and lead to brake failure.

General Guidelines

Keep these points in mind when bleeding hydraulic brakes:

• The master cylinder reservoirs have limited capacities.

It is easy to empty them during the bleeding procedure.

This introduces air into the system which you are trying

to purge. Watch the reservoir closely and add fluid

when necessary to prevent air from entering the system.

• Apply only light to moderate pressure to the lever or

pedal when bleeding the brake system. Extreme

B

E

C

D

WARNING

Contaminated brake discs or brake pads greatly reduce

braking performance and increase stopping distance.

Do not attempt to clean contaminated pads. Replace

them. Clean the brake disc with brake cleaner.

This brake system requires ethylene-glycol based fluid

(DOT 4). Do not use or mix different types of fluid such

as silicone-based or petroleum-based.

Do not use brake fluid taken from old, used or unsealed

containers. Never reuse brake fluid.

Keep brake fluid tightly sealed and out of reach of chil-

dren. Brake fluid can accumulate moisture, reducing it's

effectiveness.

A soft, spongy feeling in the brake lever and/or brake

pedal could indicate a hazardous condition in the brake

system. Do not operate the motorcycle until the failure

in the brake system is corrected.

An unsafe condition exists when air is trapped in the hy-

draulic brake system. Air in the brake hydraulic system

acts like a soft spring and absorbs a large percentage

of the pressure developed by the master cylinder. With-

out this pressure, the braking system cannot develop

full braking force to allow for safe, controlled stops. It is

extremely important to bleed the brakes properly after

any brake system work has been performed or when in-

spection reveals spongy brakes.

CAUTION

Pressure bleeding is not recommended. When fluid

surges through the fittings, it is possible to cavitate the

fluid and create air in the system. In addition, the fluid

stored in a pressure bleeder may be contaminated. Al-

ways use fresh DOT 4 brake fluid from a sealed con-

tainer.