Snowmobile Polaris EDGE / WIDETRAK (2007-2012 year). Instruction - part 35

5.38

Engine Systems

9923396 - 2007-2012 EDGE/Widetrak LX Service Manual

©2011 Polaris Sales Inc.

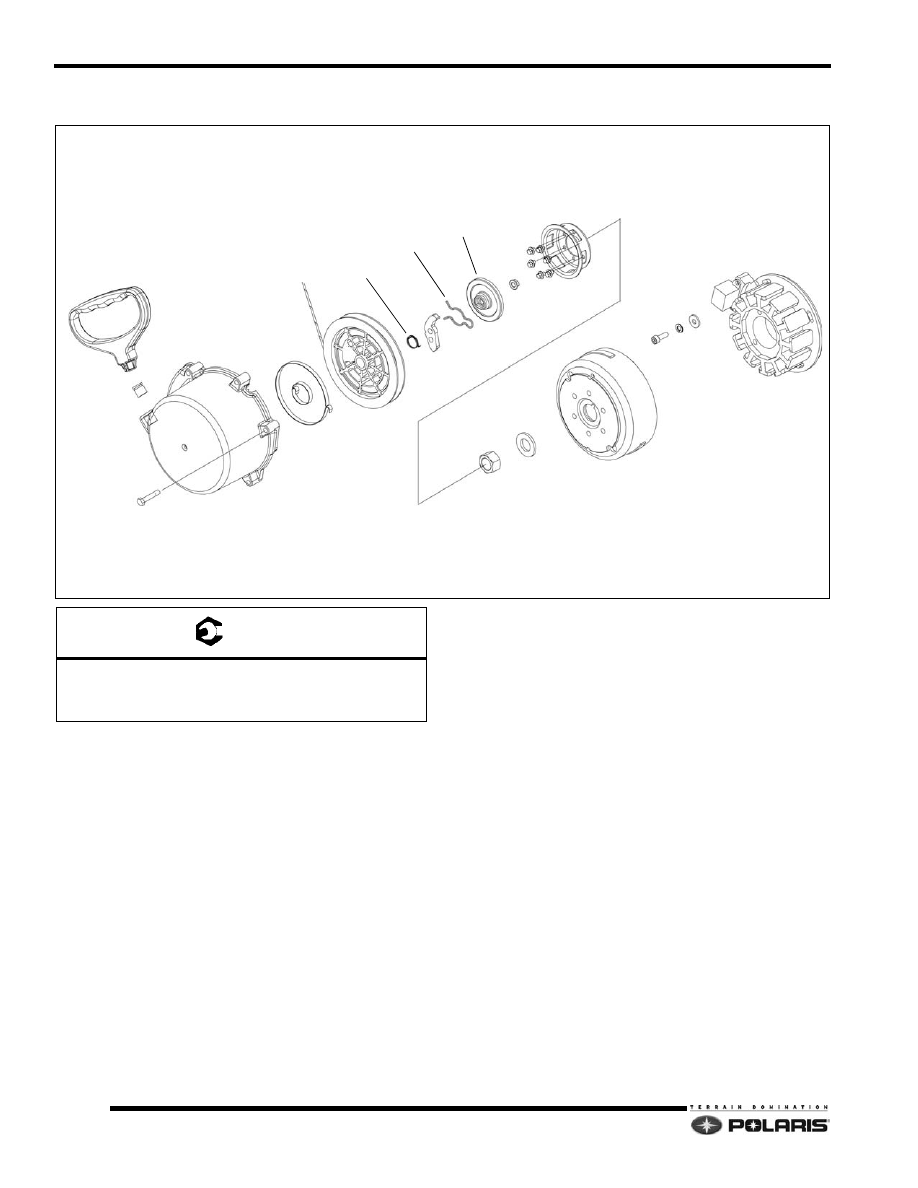

500EV Recoil / Magneto

Disassembly / Assembly Process

1.

Remove the exhaust pipe and resonator.

2.

If the recoil assembly does not require attention, the

recoil rope can remained attached to the handle. If

recoil component work is desired, reference the

Recoil Assembly section. See “Recoil Pulley” on

page 5.12.

3.

Remove the recoil / magneto housing cover. The

recoil assembly is located inside the housing.

4.

Remover the recoil hub from the flywheel. Secure the

flywheel with a strap wrench, PN PU-45419. Remove

the flywheel nut and washer.

5.

Using the flywheel puller tool, PN 2871043, insert the

puller’s three screws into the flywheel.

NOTE: Do not thread the puller screws into the

magneto/stator located behind the flywheel.

6.

Turn the puller center bolt in until the flywheel “pops”

off of the crankshaft.

7.

Mark the location of the magneto / stator plate in

several places using a scribe.

8.

Remove the magneto / stator from the crankcase.

9.

Clean the crankshaft and flywheel tapers with a

solvent such as clutch cleaner.

10. Assembly is reverse of disassembly. Reference the

fastener torque specifications at the beginning of the

chapter.

11. Do not use an impact wrench to install the flywheel

nut.

RECOIL HANDLE

ROPE GUIDE

RECOIL HOUSING

SPRING

ROPE REEL

RETURN SPRING

RATCHET

FRICTION SPRING

FRICTION PLATE

RECOIL HUB

FLYWHEEL NUT

FLYWHEEL

MAGNETO / STATOR

A

B

A

C

B

= T

A = 9 Ft.Lbs. (12 Nm)

B = 5 Ft.Lbs. (7 Nm) - Apply Loctite 242 (Stator)

C = 90 Ft.Lbs. (122 Nm) - Apply Loctite 242